Home > Press > UBCO researchers change the game when it comes to activity tracking: Flexible, highly sensitive motion device created by extrusion printing

|

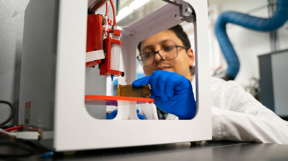

| UBC Okanagan doctoral student Ahmadreza Ghaffarkhah uses a 3D printer to create small and highly-accurate sensors that can be integrated into clothing and equipment. CREDIT UBC Okanagan photo |

Abstract:

The creation of high-resolution extrusion printing—think 3D printing but with ink that conducts electricity—has enabled UBC researchers to explore the potential of wearable human motion devices.

UBCO researchers change the game when it comes to activity tracking: Flexible, highly sensitive motion device created by extrusion printing

Kelowna, BC Canada | Posted on June 17th, 2022Wearable technology—smartwatches, heart monitors, sleep aid devices, even step counters—have become part of everyday life. And researchers with UBC Okanagan’s Nanomaterials and Polymer Nanocomposites Laboratory, have created even smaller, lighter and highly-accurate sensors that can be integrated into clothing and equipment.

In collaboration with Drexel University and the University of Toronto, the UBCO research team is exploring a high-resolution extrusion printing approach to develop tiny devices with dual functionality—electromagnetic interference (EMI) shields and a body motion sensor.

Tiny and lightweight, these EMI shields can have applications in the health care, aerospace and automotive industries, explains Dr. Mohammad Arjmand, Assistant Professor and Canada Research Chair in Advanced Materials and Polymer Engineering at UBC Okanagan's School of Engineering.

Using a two-dimensional inorganic nanomaterial called MXene, alongside a conductive polymer, Dr. Arjmand’s team has customized a conductive ink with a number of properties that make it easier to adapt into wearable technologies.

“Advanced or smart materials that provide electrical conductivity and flexibility are highly sought-after,” he says. “Extrusion printing of these conductive materials will allow for macro-scale patterning, meaning we can produce different shapes or geometries, and the product will have outstanding architecture flexibility.”

Currently, manufacturing technologies of these functional materials are mostly limited to laminated and unsophisticated structures that don’t enable the integration of monitoring technologies, explains doctoral student Ahmadreza Ghaffarkhah.

“These printed structures can be seeded with micro-cracks to develop highly sensitive sensors. Tiny cracks in their structures are used to track small vibrations in their surroundings,” says Ghaffarkhah. “These vibrations can monitor a multitude of human activities, including breathing, facial movements, talking as well as the contraction and relaxation of a muscle.”

By going back to the drawing board, the UBCO researchers were able to address a major challenge encountered by extrusion printing. Previously, the technology didn't allow for high-enough printing resolution, so it was difficult to manufacture highly precise structures.

“Compared to conventional manufacturing technologies, extrusion printing offers customization, reduction in materials waste, and rapid production, while opening up numerous opportunities for wearable and smart electronics,” explains Dr. Arjmand. “As extrusion printing techniques improve, it is opening the door to many unique innovations.”

The researchers continue to investigate additional applications for extrusion printing inks that go beyond EMI shields and wearable electronics.

The research was published in Carbon, with financial support from a Natural Sciences and Engineering Research Council of Canada Alliance Grant and Zentek Limited.

####

For more information, please click here

Contacts:

Patty Wellborn

University of British Columbia Okanagan campus

Cell: 250-317-0293

Copyright © University of British Columbia Okanagan campus

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

2 Dimensional Materials

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Water

![]() Taking salt out of the water equation October 7th, 2022

Taking salt out of the water equation October 7th, 2022

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() New discovery aims to improve the design of microelectronic devices September 13th, 2024

New discovery aims to improve the design of microelectronic devices September 13th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||