Home > Press > NRL reveals novel uniform coating process of p-ALD

|

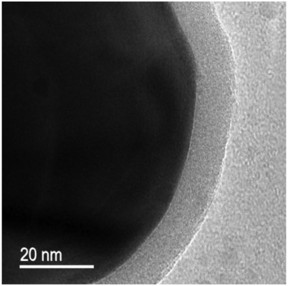

| Image shows high magnification bright field transmission electron microscopy (TEM) image showing obvious delineation of alumina film and surface of particle. In this work, performed by NRL researchers, the growth per cycle (GPC) during atomic layer deposition is compared for different batches of powder with average particle sizes ranging from nanometer (nm) to micrometer (μm). Samples prepared after depositing thin alumina films (from 10 to15 nm) on tungsten powders using particle atomic layer deposition (p-ALD) were investigated with x-ray photoelectron spectroscopy (XPS), scanning and transmission electron microscopy (SEM), and TEM. CREDIT: US Naval Research Laboratory |

Abstract:

Scientists at the U.S. Naval Research Laboratory (NRL) have devised a clever combination of materials -- when used during the thin-film growth process -- to reveal that particle atomic layer deposition, or p-ALD, deposits a uniform nanometer-thick shell on core particles regardless of core size, a discovery having significant impacts for many applications since most large scale powder production techniques form powder batches that are made up of a range of particles sizes.

NRL reveals novel uniform coating process of p-ALD

Washington, DC | Posted on April 21st, 2016"Particle atomic layer deposition is highlighted as a technology that can create new and exciting designer core/shell particles to be used as building blocks for the next generation of complex multifunctional nanocomposites," said Dr. Boris Feygelson, research engineer, NRL Electronics Science and Technology Division. "Our work is important because shell-thickness is most often a crucial parameter in applications where core-shell materials can be used to enhance performance of future materials."

Atomic layer deposition is a layer-by-layer chemical vapor deposition-based thin-film growth technique used extensively in the electronics industry to deposit nanometer-thick films of dielectric materials on devices. Combined with other deposition and shadowing masking techniques, ALD is an integral part of electronic chip and device manufacturing. The same gas-phase process can be applied in a rotary or fluidizing powder bed reactor to grow nanometer-thick films that are highly conformal and uniformly thick on individual particles.

Previous research on p-ALD, patented by ALD NanoSolutions, Inc., has shown that growth of each layer during the deposition process varies with particle size, with the underlying assumption that larger particles will always have less growth. To observe this growth phenomenon, the NRL team grew alumina on nano- and micron-sized particles of tungsten and measured the shell thickness in a transmission electron microscope. Because of the huge mass/density difference of the two materials, this pairing provides maximum contrast in the electron microscope and delineation was easily distinguishable between the particle core and shell.

In their research, the scientists created core and shell powders consisting of a tungsten particle core and thin alumina shell that were then synthesized using atomic layer deposition in a rotary reactor. Standard atomic layer deposition of trimethylaluminum and water was performed on varying batches of powder with different average particle sizes.

"Amazingly, we found that the growth per cycle of the alumina film on an individual particle in a batch was shown to be independent of the size of an individual particle, and therefore, a powder batch -- which consists of particles sizes spanning orders of magnitude -- has constant shell thicknesses on all particles. This result upsets the current understanding of ALD on particles," said Dr. Kedar Manandhar, ASEE postdoc, NRL Electronics Science and Technology Division and leading author of the research paper.

The work, published recently in the Journal of Vacuum Science and Technology A, suggests that water, a reactant in the ALD process, is reason for the same rate of growth on different particles. This uniformity of thickness on different particle sizes in a particular batch is determined to be due to the difficulty of removing residual water molecules from the powder during the purging cycle of the atomic layer deposition (ALD) process. "Water is very sticky and it is very difficult to remove the last mono-layer from surfaces," Feygelson says. "And when you have a tumbling bed of powders, the water sticks around between the particles and results in consistent shell growth in the tumbling powder.

Applications for this research demonstrate implications for use in materials like abrasion resistant paints, high surface area catalyst, electron tunneling barriers, ultra-violet adsorption or capture in sunscreens or solar cells and even beyond when core-shell nanoparticles are used as buildings blocks for making new artificial nanostructured solids with unprecedented properties.

###

This research is a cross-disciplinary effort at NRL between the Materials Science and Technology Division and Electronics Science and Technology Division. The authors of the paper gratefully acknowledge Drs. Dev Palmer (Defense Advanced Research Projects Agency), Baruch Levush (NRL), and Fritz Kub (NRL).

####

For more information, please click here

Contacts:

Daniel Parry

202-767-2326

Copyright © Naval Research Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

Chemistry

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Single-atom catalysts change spin state when boosted by a magnetic field June 4th, 2025

Single-atom catalysts change spin state when boosted by a magnetic field June 4th, 2025

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Laboratories

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Powders

![]() Graphene nanotubes offer an efficient replacement for carbon additives in conductive electrical heating paints November 3rd, 2021

Graphene nanotubes offer an efficient replacement for carbon additives in conductive electrical heating paints November 3rd, 2021

![]() Ceramics and Nanoceramic Powders Market To 2015: Acute Market Reports July 20th, 2015

Ceramics and Nanoceramic Powders Market To 2015: Acute Market Reports July 20th, 2015

![]() Global Nanoclays Market Analysis, Size, Growth, Trends And Segment Forecasts, 2015 To 2022: Grand View Research, Inc June 15th, 2015

Global Nanoclays Market Analysis, Size, Growth, Trends And Segment Forecasts, 2015 To 2022: Grand View Research, Inc June 15th, 2015

![]() Reducing energy usage with nano-coatings April 9th, 2015

Reducing energy usage with nano-coatings April 9th, 2015

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Water

![]() Taking salt out of the water equation October 7th, 2022

Taking salt out of the water equation October 7th, 2022

Personal Care/Cosmetics

![]() DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

![]() A Comprehensive Guide: The Future of Nanotechnology September 13th, 2018

A Comprehensive Guide: The Future of Nanotechnology September 13th, 2018

![]() Graphene finds new application as anti-static hair dye: New formula works as well as commercial permanent dyes without chemically altering hairs March 22nd, 2018

Graphene finds new application as anti-static hair dye: New formula works as well as commercial permanent dyes without chemically altering hairs March 22nd, 2018

![]() Programmable materials find strength in molecular repetition May 23rd, 2016

Programmable materials find strength in molecular repetition May 23rd, 2016

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||