Home > Press > Break-through Carbon Nanotube Assembly on Polymer Surface

|

Abstract:

MicroDysis developed a straightforward and effective technique to entrap single-walled carbon nanotubes upright onto a polymer surface, which provides an ideal matrix for maximum detection sensitivity in (bio)chemical applications.

Break-through Carbon Nanotube Assembly on Polymer Surface

Bordentown, NJ | Posted on July 30th, 2009MicroDysis develops and markets biomedical and environmental devices and systems that use embedded carbon nanotubes to solve a wide variety of real-world problems. The Company's patented micro-molding fabrication and nanotube assembly techniques are able to embed vertically oriented carbon nanotubes into a polymer matrix. Recently, MicroDysis demonstrated this technique to entrap single-walled carbon nanotubes (SWNTs) onto a polymer surface, such as elastomer or silicone rubber, and plastics. This approach increases the functionalized surface of a device by 10,000 times and provides an ideal matrix for attaching molecular probes and other chemically active absorbers for maximum detection sensitivity. MicroDysis further developed an 8-well strip microplate with the bottom surface entrapped SWNTs for pharmaceutical and biomedical applications.

Assembly of carbon nanotubes from as-grown randomly tangled states into well-ordered and uniform manner has attracted considerable attentions worldwide due to specific properties of the carbon nanotubes and its importance for chemical, biomedical and engineering applications. Carbon nanotubes show their superior properties for immobilizing biomolecules with a three-dimensional nano-architecture and highly dense functional groups on the surfaces. For sensors, biochips, and many other applications, the well-ordered and functionalized carbon nanotubes are greatly desirable. However, the creation of properly oriented nanotubes remains a big challenge due to their fragility and that technology has not been broadly commercialized.

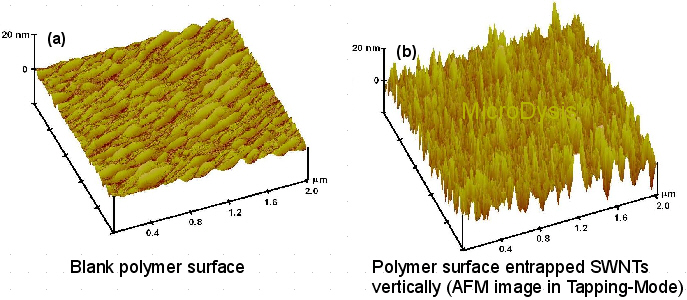

Atomic Force Microscope (AFM ) images (in Tapping-Mode) shows that SWNTs are vertically assembled on polymer surface. The average height of the entrapped SWNTs is around 40 nm. The nanotubular features of the nanotubes on the surface significantly enhance the surface area to about 10,000 times greater than a blank surface. With the functionalized surface feature (-COOH groups) on the nanotubes, this technique will find broad wide application in immobilizing sensing molecules for DNA assays, protein analysis, and chemical compound and ion detection.

Advantages of this technique:

1. Vertical assembled single-walled carbon nanotubes on polymer matrix.

2. Surface area increased about 10,000 times.

3. Highly dense-COOH groups for chemically binding sensing molecules.

4. Versatile sensing platform.

####

About MicroDysis

MicroDysis designs and manufactures a wide variety of microfluidic devices and instrumentation. The Company focuses on enhancing test sensitivity using its patented micro-fabrication technology for embedding functionalized carbon nanotubes onto surfaces of channels and micro-wells.

For more information, please click here

Contacts:

Joseph Huang

MicroDysis, Inc.

Copyright © MicroDysis

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Chemistry

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Homeland Security

![]() The picture of health: Virginia Tech researchers enhance bioimaging and sensing with quantum photonics June 30th, 2023

The picture of health: Virginia Tech researchers enhance bioimaging and sensing with quantum photonics June 30th, 2023

![]() Sensors developed at URI can identify threats at the molecular level: More sensitive than a dog's nose and the sensors don't get tired May 21st, 2021

Sensors developed at URI can identify threats at the molecular level: More sensitive than a dog's nose and the sensors don't get tired May 21st, 2021

![]() Highly sensitive dopamine detector uses 2D materials August 7th, 2020

Highly sensitive dopamine detector uses 2D materials August 7th, 2020

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||