Home > Press > Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels

|

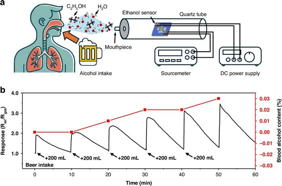

| Real-time monitoring of exhaled breath ethanol concentration using the sensor. a Schematic illustration of the experimental setup. The subject consumed 200 mL of beer every 10 min, with BrAC measurements taken prior to each intake. Breath ethanol concentration was measured using two devices: a commercial breathalyzer (Alcoscan AL8800, Sentech Korea Corp.) as a reference, and the developed ethanol sensor integrated with a measurement system. b BrAC response recorded over time. The developed ethanol sensor demonstrated a strong correlation with the reference breathalyzer, effectively tracking changes in breath ethanol concentration. The sensor successfully captured transient ethanol spikes and exhibited a rapid response to alcohol intake, confirming its potential for real-time breath alcohol monitoring applications. Credit Microsystems & Nanoengineering |

Abstract:

Accurate detection of ethanol at extremely low concentrations is essential for applications ranging from industrial safety to health monitoring, yet existing sensors often struggle to balance sensitivity, selectivity, and power efficiency. In this study, researchers developed a chemiresistive gas sensor that dramatically improves ethanol detection by integrating ultrathin catalytic nanosheets onto a conventional metal-oxide sensing film. The resulting device responds strongly to ethanol at concentrations spanning from parts per million down to a few parts per billion, representing a substantial performance gain over unmodified sensors. By combining enhanced surface reactions with amplified electronic signal transduction, the new sensor achieves exceptional sensitivity while maintaining stable, low-power operation, opening new opportunities for compact and reliable ethanol monitoring technologies.

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels

Beijing, China | Posted on January 30th, 2026Ethanol is widely used in industrial processing, food production, medical diagnostics, and transportation, but its volatility and potential health risks demand reliable monitoring at low concentrations. Conventional metal-oxide gas sensors are attractive because of their simplicity and low cost, yet they typically require high operating temperatures and show limited sensitivity or poor selectivity at trace ethanol levels. Environmental humidity and signal instability further complicate real-world deployment. Improving sensor performance therefore requires new material strategies that can accelerate surface reactions while amplifying electrical responses without increasing power consumption. Based on these challenges, it is necessary to conduct in-depth research into advanced functional materials that can fundamentally enhance ethanol gas sensing performance.

Researchers from Yonsei University and collaborating institutions reported (DOI: 10.1038/s41378-025-01055-6) this advance on November 7, 2025, in Microsystems & Nanoengineering. The team designed a microheater-integrated gas sensor in which ultrathin ruthenium dioxide nanosheets were deposited onto a tin dioxide thin film. This hybrid structure enabled ultra-sensitive ethanol detection across a wide concentration range, including parts-per-billion levels, while operating at low power. Beyond laboratory testing, the sensor also demonstrated real-time tracking of breath alcohol concentration, highlighting its potential for practical safety and health-related applications.

The core innovation lies in functionalizing a traditional tin-oxide sensing layer with monolayer-scale ruthenium dioxide nanosheets. These nanosheets provide an exceptionally high surface-to-volume ratio and strong catalytic activity, which together accelerate ethanol oxidation reactions on the sensor surface. At the same time, electronic interactions at the interface between the two materials create an expanded electron depletion layer, amplifying resistance changes when ethanol is present. As a result, the sensor’s response to ethanol increased by more than threefold compared with an unmodified device.

The sensor was fabricated on a suspended membrane platform incorporating a microheater, minimizing heat loss and enabling continuous operation below 30 milliwatts. Systematic testing showed reliable detection from 10 parts per million down to approximately 5 parts per billion, placing the device among the most sensitive chemiresistive ethanol sensors reported to date. The sensor also exhibited improved selectivity against common interfering gases, stable operation over nearly a month, and reproducible performance across repeated sensing cycles. Importantly, controlled experiments demonstrated that the device could track dynamic changes in breath alcohol concentration in real time, closely matching readings from a commercial breathalyzer.

“This work shows how nanoscale material engineering can fundamentally change the performance limits of conventional gas sensors,” the researchers noted. By leveraging both catalytic and electronic sensitization effects, the design achieves a rare combination of ultra-high sensitivity, low power consumption, and operational stability. They emphasized that the integration of nanosheets onto a scalable thin-film platform makes the approach compatible with existing microfabrication technologies, which is essential for translating laboratory advances into practical sensing devices.

The ultra-sensitive ethanol sensor has implications well beyond laboratory demonstrations. In industrial environments, it could provide early warnings of ethanol leaks or vapor buildup, improving fire prevention and worker safety. In healthcare and transportation, compact and low-power sensors could enable next-generation breath analyzers for real-time alcohol monitoring, supporting medical diagnostics and drunk-driving prevention systems. More broadly, the nanosheet-functionalization strategy can be extended to other target gases, offering a versatile pathway for developing high-performance sensors for environmental monitoring, smart infrastructure, and wearable health technologies.

####

About Microsystems & Nanoengineering

Microsystems & Nanoengineering is an online-only, open access international journal devoted to publishing original research results and reviews on all aspects of Micro and Nano Electro Mechanical Systems from fundamental to applied research. The journal is published by Springer Nature in partnership with the Aerospace Information Research Institute, Chinese Academy of Sciences, supported by the State Key Laboratory of Transducer Technology.

For more information, please click here

Contacts:

Na Li

Microsystems & Nanoengineering

Copyright © Microsystems & Nanoengineering

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

![]() Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Sensors

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Industrial

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Safety-Nanoparticles/Risk management

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

![]() Closing the gaps — MXene-coating filters can enhance performance and reusability February 28th, 2025

Closing the gaps — MXene-coating filters can enhance performance and reusability February 28th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||