Home > Press > New surface treatment could improve refrigeration efficiency: A slippery surface for liquids with very low surface tension promotes droplet formation, facilitating heat transfer

|

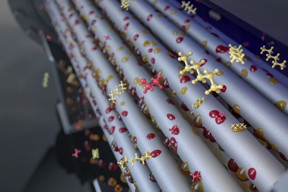

| Artistic rendition of a dropwise condensing shell and tube heat exchanger, where vapor molecules condense onto heat exchange tubes and form drops that shed from the surface. The different colors and shapes represent different vapor materials. Illustration by Demin Liu |

Abstract:

Unlike water, liquid refrigerants and other fluids that have a low surface tension tend to spread quickly into a sheet when they come into contact with a surface. But for many industrial processes it would be better if the fluids formed droplets, which could roll or fall off the surface and carry heat away with them.

New surface treatment could improve refrigeration efficiency: A slippery surface for liquids with very low surface tension promotes droplet formation, facilitating heat transfer

Cambridge, MA | Posted on May 17th, 2019Now, researchers at MIT have made significant progress in promoting droplet formation and shedding in such fluids. This approach could lead to efficiency improvements in many large-scale industrial processes including refrigeration, thus saving energy and reducing greenhouse gas emissions.

The new findings are described in the journal Joule, in a paper by recent graduate and postdoc Karim Khalil PhD '18, professor of mechanical engineering Kripa Varanasi, professor of chemical engineering and Associate Provost Karen Gleason, and four others.

Over the years, Varanasi and his collaborators have made great progress in improving the efficiency of condensation systems that use water, such as the cooling systems used for fossil-fuel or nuclear power generation. But other kinds of fluids — such as those used in refrigeration systems, liquification, waste heat recovery, and distillation plants, or materials such as methane in oil and gas liquifaction plants — often have very low surface tension compared to water, meaning that it is very hard to get them to form droplets on a surface. Instead, they tend to spread out in a sheet, a property known as wetting.

But when these sheets of liquid coat a surface, they provide an insulating layer that inhibits heat transfer, and easy heat transfer is crucial to making these processes work efficiently. “If it forms a film, it becomes a barrier to heat transfer,” Varanasi says. But that heat transfer is enhanced when the liquid quickly forms droplets, which then coalesce and grow and fall away under the force of gravity. Getting low-surface-tension liquids to form droplets and shed them easily has been a serious challenge.

In condensing systems that use water, the overall efficiency of the process can be around 40 percent, but with low-surface-tension fluids, the efficiency can be limited to about 20 percent. Because these processes are so widespread in industry, even a tiny improvement in that efficiency could lead to dramatic savings in fuel, and therefore in greenhouse gas emissions, Varanasi says.

By promoting droplet formation, he says, it’s possible to achieve a four- to eightfold improvement in heat transfer. Because the condensation is just one part of a complex cycle, that translates into an overall efficiency improvement of about 2 percent. That may not sound like much, but in these huge industrial processes even a fraction of a percent improvement is considered a major achievement with great potential impact. “In this field, you’re fighting for tenths of a percent,” Khalil says.

Unlike the surface treatments Varanasi and his team have developed for other kinds of fluids, which rely on a liquid material held in place by a surface texture, in this case they were able to accomplish the fluid-repelling effect using a very thin solid coating — less than a micron thick (one millionth of a meter). That thinness is important, to ensure that the coating itself doesn’t contribute to blocking heat transfer, Khalil explains.

The coating, made of a specially formulated polymer, is deposited on the surface using a process called initiated chemical vapor deposition (iCVD), in which the coating material is vaporized and grafts onto the surface to be treated, such as a metal pipe, to form a thin coating. This process was developed at MIT by Gleason and is now widely used.

The authors optimized the iCVD process by tuning the grafting of coating molecules onto the surface, in order to minimize the pinning of condensing droplets and facilitate their easy shedding. The process could be carried out on location in industrial-scale equipment, and could be retrofitted into existing installations to provide a boost in efficiency. The process is “materials agnostic,” Khalil says, and can be applied on either flat surfaces or tubing made of stainless steel, titanium, or other metals commonly used in condensation heat-transfer processes that involve these low-surface-tension fluids. “Whatever materials are used in your facility's heat exchanger, it tends to be scalable with this process,” he adds.

The net result is that on these surfaces, condensing fluids like the hydrocarbons pentane or liquid methane, or alcohols like ethanol, will readily form small droplets that quickly fall off the surface, making room for more to form, and in the process shedding heat from the metal to the droplets that fall away.

One area where such coatings could play a useful role, Varanasi says, is in organic Rankine cycle systems, which are widely used for generating power from waste heat in a variety of industrial processes. “These are inherently inefficient systems,” he says, “but this could make them more efficient.”

“This new approach to condensation is significant because it promotes drop formation (rather than film formation) even for low-surface-tension fluids, which significantly improves the heat transfer efficiency,” says Jonathan Boreyko, an assistant professor of mechanical engineering at Virginia Tech, who was not connected to this research. While the iCVD process itself is not new, he says, “showing here that it can be used even for the condensation of low-surface-tension fluids is of significant practical importance, as many real-life phase-change systems do not use water.”

Saying the work is “of very high quality,” Boreyko adds that “simply showing for the first time that a thin, durable, and dry coating can promote the dropwise condensation of low-surface-tension fluids is very important for a wide variety of practical condenser systems.”

The research was supported by the Shell-MIT Energy Initiative partnership. The team included former MIT graduate students Taylor Farnham and Adam Paxson, and former postdocs Dan Soto and Asli Ugur Katmis.

####

For more information, please click here

Contacts:

Karl-Lydie Jean-Baptiste

Phone: (617) 253-1682

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Environment

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Home

![]() Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

![]() Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

![]() Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Iran Develops Water-Repellent Nano-Paint December 5th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||