Home > Press > Carbon nanotube 'stitches' make stronger, lighter composites: Method to reinforce these materials could help make airplane frames lighter, more damage-resistant

|

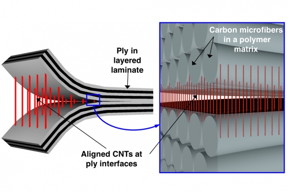

| The researchers’ technique integrates a scaffold of carbon nanotubes within a polymer glue. They first grew a forest of vertically-aligned carbon nanotubes and transferred it onto a sticky, uncured composite layer. Then they repeated the process to generate a stack of 16 composite plies, with carbon nanotubes glued between each layer.

Courtesy of the researchers |

Abstract:

The newest Airbus and Boeing passenger jets flying today are made primarily from advanced composite materials such as carbon fiber reinforced plastic -- extremely light, durable materials that reduce the overall weight of the plane by as much as 20 percent compared to aluminum-bodied planes. Such lightweight airframes translate directly to fuel savings, which is a major point in advanced composites' favor.

Carbon nanotube 'stitches' make stronger, lighter composites: Method to reinforce these materials could help make airplane frames lighter, more damage-resistant

Cambridge, MA | Posted on August 4th, 2016But composite materials are also surprisingly vulnerable: While aluminum can withstand relatively large impacts before cracking, the many layers in composites can break apart due to relatively small impacts -- a drawback that is considered the material's Achilles' heel.

Now MIT aerospace engineers have found a way to bond composite layers in such a way that the resulting material is substantially stronger and more resistant to damage than other advanced composites. Their results are published this week in the journal Composites Science and Technology.

The researchers fastened the layers of composite materials together using carbon nanotubes -- atom-thin rolls of carbon that, despite their microscopic stature, are incredibly strong. They embedded tiny "forests" of carbon nanotubes within a glue-like polymer matrix, then pressed the matrix between layers of carbon fiber composites. The nanotubes, resembling tiny, vertically-aligned stitches, worked themselves within the crevices of each composite layer, serving as a scaffold to hold the layers together.

In experiments to test the material's strength, the team found that, compared with existing composite materials, the stitched composites were 30 percent stronger, withstanding greater forces before breaking apart.

Roberto Guzman, who led the work as an MIT postdoc in the Department of Aeronautics and Astronautics (AeroAstro), says the improvement may lead to stronger, lighter airplane parts -- particularly those that require nails or bolts, which can crack conventional composites.

"More work needs to be done, but we are really positive that this will lead to stronger, lighter planes," says Guzman, who is now a researcher at the IMDEA Materials Institute, in Spain. "That means a lot of fuel saved, which is great for the environment and for our pockets."

The study's co-authors include AeroAstro professor Brian Wardle and researchers from the Swedish aerospace and defense company Saab AB.

"Size matters"

Today's composite materials are composed of layers, or plies, of horizontal carbon fibers, held together by a polymer glue, which Wardle describes as "a very, very weak, problematic area." Attempts to strengthen this glue region include Z-pinning and 3-D weaving -- methods that involve pinning or weaving bundles of carbon fibers through composite layers, similar to pushing nails through plywood, or thread through fabric.

"A stitch or nail is thousands of times bigger than carbon fibers," Wardle says. "So when you drive them through the composite, you break thousands of carbon fibers and damage the composite."

Carbon nanotubes, by contrast, are about 10 nanometers in diameter -- nearly a million times smaller than the carbon fibers.

"Size matters, because we're able to put these nanotubes in without disturbing the larger carbon fibers, and that's what maintains the composite's strength," Wardle says. "What helps us enhance strength is that carbon nanotubes have 1,000 times more surface area than carbon fibers, which lets them bond better with the polymer matrix."

Stacking up the competition

Guzman and Wardle came up with a technique to integrate a scaffold of carbon nanotubes within the polymer glue. They first grew a forest of vertically-aligned carbon nanotubes, following a procedure that Wardle's group previously developed. They then transferred the forest onto a sticky, uncured composite layer and repeated the process to generate a stack of 16 composite plies -- a typical composite laminate makeup -- with carbon nanotubes glued between each layer.

To test the material's strength, the team performed a tension-bearing test -- a standard test used to size aerospace parts -- where the researchers put a bolt through a hole in the composite, then ripped it out. While existing composites typically break under such tension, the team found the stitched composites were stronger, able to withstand 30 percent more force before cracking.

The researchers also performed an open-hole compression test, applying force to squeeze the bolt hole shut. In that case, the stitched composite withstood 14 percent more force before breaking, compared to existing composites.

"The strength enhancements suggest this material will be more resistant to any type of damaging events or features," Wardle says. "And since the majority of the newest planes are more than 50 percent composite by weight, improving these state-of-the art composites has very positive implications for aircraft structural performance."

###

This work was supported by Airbus Group, Boeing, Embraer, Lockheed Martin, Saab AB, Spirit AeroSystems Inc., Textron Systems, ANSYS, Hexcel, and TohoTenax through MIT's Nano-Engineered Composite aerospace STructures (NECST) Consortium and, in part, by the U.S. Army.

####

For more information, please click here

Contacts:

Karl-Lydie Jean-Baptiste

617-253-1682

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() New discovery aims to improve the design of microelectronic devices September 13th, 2024

New discovery aims to improve the design of microelectronic devices September 13th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||