Home > Press > Veeco Introduces “FastLine” Glass Coating Platform: For Production of CIGS Thin Film Solar Cells

|

Abstract:

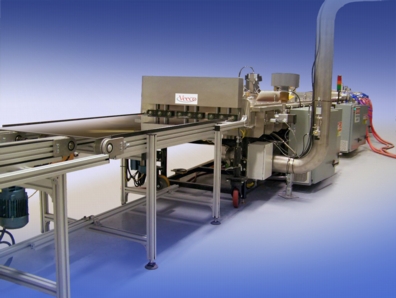

Veeco Instruments Inc. (Nasdaq: VECO), announced the introduction of its FastLine™ platform of Glass Coating Systems, leveraging Veeco's proven PV-Series™ Thermal Deposition Sources. Veeco's new FastLine platform is designed for high throughput, low cost of ownership production of CIGS (copper, indium, gallium and selenium) solar cells.

Veeco Introduces “FastLine” Glass Coating Platform: For Production of CIGS Thin Film Solar Cells

Plainview, NY | Posted on April 27th, 2009Piero Sferlazzo, Ph.D., Senior Vice President of Veeco's Solar Equipment business, commented, "Veeco is now the only equipment company offering integrated production-scale solutions for CIGS manufacturing on glass using thermal evaporation sources for the CIGS/absorber layer. Customers can now choose Veeco to provide comprehensive, fully integrated equipment to manufacture CIGS solar cells, whether they choose to use our FastLine systems for glass or our FastFlex™ systems for flexible substrates."

Thermal evaporation, as compared to other deposition methods, produces the highest efficiency thin film solar cells and has the lowest materials costs with high material utilization driving down the manufacturing cost per watt. Veeco's FastLine systems can handle up to thirty 1.1m x 1.4m glass panels/hour. The modular architecture of the system allows customers to scale their output according to their needs.

The U.S. Department of Energy's National Renewable Energy Laboratory (NREL) has claimed a world record for CIGS thin-film solar cell conversion efficiency of 19.9 percent. The conversion efficiency for CIGS is now close to that of multi-crystalline silicon-based solar cells, according to NREL. This achievement was hailed as an important milestone because the efficiency of thin film solar cells is now achieving its goal of matching silicon in performance.

####

About Veeco Instruments Inc.

Veeco Instruments Inc. manufactures enabling solutions for customers in the HB-LED, solar, data storage, semiconductor, scientific research and industrial markets. We have leading technology positions in our three businesses: LED & Solar Process Equipment, Data Storage Process Equipment, and Metrology Instruments. Veeco’s manufacturing and engineering facilities are located in New York, New Jersey, California, Colorado, Arizona, Massachusetts and Minnesota. Global sales and service offices are located throughout the U.S., Europe, Japan and APAC.

To the extent that this news release discusses expectations or otherwise makes statements about the future, such statements are forward-looking and are subject to a number of risks and uncertainties that could cause actual results to differ materially from the statements made. These factors include the risks discussed in the Business Description and Management's Discussion and Analysis sections of Veeco's Annual Report on Form 10-K for the year ended December 31, 2008 and in our subsequent quarterly reports on Form 10-Q, current reports on Form 8-K and press releases. Veeco does not undertake any obligation to update any forward-looking statements to reflect future events or circumstances after the date of such statements.

For more information, please click here

Contacts:

Investor Contact:

Deb Wasser

SVP

Investor Relations

1-516-677-0200 x 1472

Trade Media Contact:

Fran Brennen

Senior Director of Marcom

1-516-677-0200 x1222

Copyright © Veeco Instruments Inc.

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||