Home > Press > A new take on the Midas touch - changing the colour of gold

|

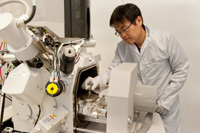

| The tiny patterns are formed on the gold surface using a process called ion beam milling (the focused ion beam system is used to create nanoscale intaglio metamaterial patterns on the metal surface. Here we can see the gold substrate being loaded. |

Abstract:

Red gold, green gold - a ground-breaking initiative has found a way of changing the colour of the world's most iconic precious metal.

A University of Southampton team have discovered that by embossing tiny raised or indented patterns onto the metal's surface they can change the way it absorbs and reflects light - ensuring our eyes don't see it as ‘golden' in colour at all.

A new take on the Midas touch - changing the colour of gold

Southampton, UK | Posted on October 24th, 2012The finding results from a major initiative funded by the Engineering and Physical Sciences Research Council (EPSRC) targeting the development of a new generation of nanotechnology-enabled materials.

Equally applicable to other metals such as silver and aluminium, this breakthrough opens up the prospect of colouring metals without having to coat or chemically treat them. This could deliver valuable economic, environmental and other benefits.

The technique could be harnessed in a wide range of industries for anything from manufacturing jewellery to making banknotes and documents harder to forge.

"This is the first time the visible colour of metal has been changed in this way," says Professor Nikolay Zheludev, Deputy Director of Southampton's Optoelectronics Research Centre, who led the project.

"The colours of the objects we see all around us are determined by the way light interacts with those objects. For instance, an object that reflects red light but absorbs other wavelengths will appear red to the human eye.

"This is the fundamental principle we have exploited in this project. By embossing metals with patterns only around 100 nanometres across, we've found that we can control which wavelengths of light the metal absorbs and which it reflects." *

The precise shape and height or depth of the patterns determine exactly how light behaves when it strikes the metal and therefore what colour is created. The technique can be used to produce a wide range of colours on a given metal.

A silver ring, for example, could be decorated with a number of different patterns, making one part of it appear red, another part green and so on; metal features with sophisticated optical properties that would be almost impossible to imitate could be incorporated into documents as security features.

The nano-patterning is carried out at the research level using well-established techniques such as ion beam milling, which may be envisaged as sand-blasting on the atomic scale.

However, the concept may be scaled for industrial production using such processes as nano-imprint, whereby large areas are stamped out from a master template in a manner comparable to CD/DVD production.

"We've filed a patent application to cover our work," Professor Zheludev says, "and we're currently talking to a number of organisations about taking our breakthrough towards commercialisation."

####

About EPSRC

EPSRC is the main UK government agency for funding research and training in engineering and the physical sciences, investing more than £850 million a year in a broad range of subjects – from mathematics to materials science, and from information technology to structural engineering.

About the University of Southampton

The University of Southampton is a leading UK teaching and research institution with a global reputation for leading-edge research and scholarship across a wide range of subjects in engineering, science, social sciences, health and humanities.

With over 22,000 students, around 5000 staff, and an annual turnover of over £350 million, the University of Southampton is acknowledged as one of the country's top institutions for engineering, computer science and medicine. We combine academic excellence with an innovative and entrepreneurial approach to research, supporting a culture that engages and challenges students and staff in their pursuit of learning.

The University is also home to a number of world-leading research centres, including the National Oceanography Centre, Southampton, the Institute of Sound and Vibration Research, the Optoelectronics Research Centre, the Centre for the Developmental Origins of Health and Disease, the Mountbatten Centre for International Studies and the Southampton Statistical Sciences Research Institute

About the Optoelectronics Research Centre

The Optoelectronics Research Centre at the University of Southampton is one of the largest university-based research groups entirely devoted to optoelectronics in the world, and has maintained a position at the forefront of photonics research for over four decades. Its long and well established track record in the fields of optical fibre, lasers, waveguides, devices and optoelectronic materials has fostered innovation, enterprise, cross-boundary and multi-disciplinary activities.

It has built strong links with industry, research institutions and universities around the world, from informal collaborations to large-scale funding. Several spin out companies, including Southampton Photonics Inc, Stratophase Ltd, Mesophotonics Ltd and ChG Southampton Ltd, have commercialised the fruits of ORC research; while its extensive outreach programme has brought lasers and optical fibres into schools across the country.

For more information, please click here

Contacts:

Kevin MacDonald

Tel: 023 8059 3085

ORC media contact:

Deanna Standen

University of Southampton

Te: 023 8059 4509

Copyright © EPSRC

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Patents/IP/Tech Transfer/Licensing

![]() Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

![]() Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

![]() Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||