Home > Press > Fitter Frames: Nanotubes Boost Structural Integrity of Composites

|

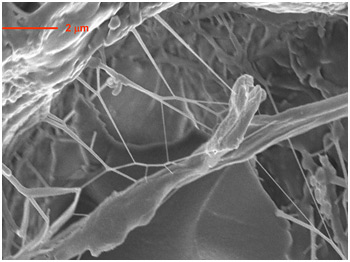

| Researchers at Rensselaer have discovered a new technique for provoking unusual crazing behavior in epoxy composites. The crazing, which causes the composite to deform into a network of nanoscale pillar-like fibers that bridge together both sides of a crack and slow its growth, could lead to tougher, more durable components for aircraft and automobiles. |

Abstract:

New research finding could lead to more durable aircraft, automotive components

Fitter Frames: Nanotubes Boost Structural Integrity of Composites

Troy, NY | Posted on March 27th, 2009A new research discovery at Rensselaer Polytechnic Institute could lead to tougher, more durable composite frames for aircraft, watercraft, and automobiles.

Epoxy composites are increasingly being incorporated into the design of new jets, planes, and other vehicles. Composite material frames are extremely lightweight, which lowers the overall weight of the vehicle and boosts fuel efficiency. The downside is that epoxy composites can be brittle, which is detrimental to its structural integrity.

Professor Nikhil Koratkar, of Rensselaer's Department of Mechanical, Aerospace, and Nuclear Engineering, has demonstrated that incorporating chemically treated carbon nanotubes into an epoxy composite can significantly improve the overall toughness, fatigue resistance, and durability of a composite frame.

When subjected to repetitive stress, a composite frame infused with treated nanotubes exhibited a five-fold reduction in crack growth rate as compared to a frame infused with untreated nanotubes, and a 20-fold reduction when compared to a composite frame made without nanotubes.

This newfound toughness and crack resistance is due to the treated nanotubes, which enhance the molecular mobility of the epoxy at the interface where the two materials touch. When stressed, this enhanced mobility enables the epoxy to craze - or result in the formation of a network of pillar-like fibers that bridge together both sides of the crack and slow its growth.

"This crazing behavior, and the bridging fibers it produces, dramatically slows the growth rate of a crack," Koratkar said. "In order for the crack to grow, those fibers have to first stretch, deform plastically, and then break. It takes a lot of energy to stretch and break those fibers, energy that would have otherwise gone toward enlarging the crack."

Results of the study were published this week in the journal Small.

Epoxy composites infused with carbon nanotubes are known to be more resistant to cracks than pure epoxy composites, as the nanotubes stitch, or bridge, the two sides of the crack together. Infusing an epoxy with carbon nanotubes that have been functionalized, or treated, with the chemical group amidoamine, however, results in a completely different bridging phenomenon.

At the interface of the functionalized nanotubes and the epoxy, the epoxy starts to craze, which is a highly unusual behavior for this particular type of composite, Koratkar said. The epoxy deforms, becomes more fluid, and creates connective fibers up to 10 microns in length and with a diameter between 100 nanometers and 1,000 nanometers.

"We didn't expect this at all. Crazing is common in certain types of thermoplastic polymers, but very unusual in the type of epoxy composite we used," Koratkar said. "In addition to improved fatigue resistance and toughness, the treated nanotubes also enhanced the stiffness, hardness, and strength of the epoxy composite, which is very important for structural applications."

Koratkar said the aircraft, boat, and automobile industries are increasingly looking to composites as a building material to make vehicle frames and components lighter. His research group plans to further investigate crazing behavior in epoxy composites, in order to better understand why the chemical treatment of nanotubes initiates crazing.

Co-authors of the paper include Rensselaer Associate Professor Catalin Picu, of the Department of Mechanical, Aerospace, and Nuclear Engineering; Rensselaer doctoral students Wei Zhang and Iti Srivastava; and Yue-Feng Zhu, professor in the Department of Mechanical Engineering at Tsinghua University in China.

Visit Koratkar's Web site http://www.eng.rpi.edu/mane/faculty_details.cfm?facultyID=koratn&type=research for more information on his nanomaterials research.

####

About Rensselaer Polytechnic Institute

RPI is widely recognized for the effectiveness of its hands-on approach to undergraduate education. Rensselaer’s classrooms are a model for intellectual engagement and the interaction of students and faculty.

In both curriculum reform and creative use of new teaching techniques and technologies, Rensselaer’s leadership in interactive learning has helped to further transform the way we teach and learn.

Contacts:

Jason B. Gorss

Manager of Media Relations

(518) 276-6098

Copyright © Rensselaer Polytechnic Institute

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Marine/Watercraft

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Automotive/Transportation

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||