Home > Press > NRL scientists produce carbon nanotubes using commercially available polymeric resins

|

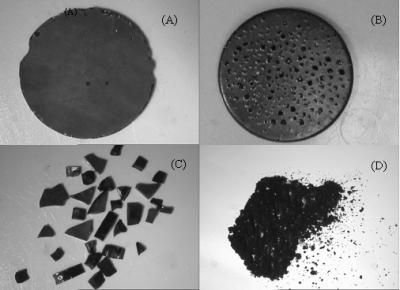

| Images of (A,B) shaped CNT solids monoliths, (C) shards, and (D) powders derived from said monoliths.

Credit: Naval Research Laboratory |

Abstract:

Scientists at the Naval Research Laboratory (NRL) have successfully produced carbon nanotubes (CNTs) in high yields in bulk solid compositions using commercially available aromatic containing resins. The concentration of multi-walled carbon nanotubes (MWNTs) and metal nanoparticles can be easily varied within the shaped carbonaceous solid. Carbon nanotube containing fibers and films have also been formulated from the precursor compositions. The potential range of applications is huge, including structure, energy, sensors, separation/filtration, battery, electronic displays, and nanoelectronic devices.

NRL scientists produce carbon nanotubes using commercially available polymeric resins

Washington, DC | Posted on February 7th, 2008Using this method, carbon nanotubes (CNTs) are formed in a bulk carbonaceous solid from thermal decomposition of melt-processable precursor compositions formulated from organometallic compounds or metal salts in the presence of an excess amount of selected highly aromatic compounds. The CNTs obtained by this patented method are not formed from gaseous components, as is common with the current CNT production based on chemical vapor deposition (CVD) methods, but rather evolve from metal and carbon nanoparticles that form within the carbonaceous solid during the carbonization process above 500°C. Only a small amount of the organometallic compound or metal salt is needed to achieve the formation of CNTs in high yield, but large quantities of the metal source can be used, depending on the application, if desired.

The solid-state method enables the large-scale production of MWNTs in moldable solid forms, films, and fibers using low-cost precursors and equipment, thereby reducing economic barriers that are inherent with carbon nanotube materials produced by more conventional methods, such as CVD. Following carbonization, the shaped carbon solids are composed of varying amounts of nanotubes and amorphous carbon, depending on such synthetic parameters as the metal catalyst concentration, carbonization temperature, and the specific organic precursors used. The amorphous carbon phase is readily removed via selective combustion at temperatures from 300-500 °C, producing highly porous, purified CNT solids with specific surface areas up to 500 m2 g-1. This highly flexible synthetic method also offers the ability to incorporate heteroatoms, for example nitrogen, oxygen, and/or boron, into the carbon nanotube solid via the initial carbon precursors.

The NRL scientists use standard resin melt processing techniques to produce various shaped CNT-containing carbonaceous configurations. Their research is the first example of using high temperature thermosetting resins as a carbon source for the formation of CNTs. Any commercially available resins, including phthalonitriles resins, polyimides, epoxy resins, phenolics, and petroleum pitches, that have good thermal properties and show superior structural integrity, are attractive sources of carbon for CNT formation by the novel method.

The use of commercially available resins is a potentially inexpensive route to CNTs. Using this simple, potentially cost-effective method could result in the production of CNTs in large quantities and various shapes. Scientists are evaluating them for possible use in numerous aerospace, marine, and electronic applications.

The NRL research team consists of Drs. Teddy Keller, Matthew Laskoski, and Jeff Long from the Chemistry Division and Dr. Syed Qadri from the Materials Science and Technology Division. The research is funded by NRL base funds provided by the Office of Naval Research.

####

About Naval Research Laboratory

NRL operates as the Navy's full-spectrum corporate laboratory, conducting a broadly based multidisciplinary program of scientific research and advanced technological development directed toward maritime applications of new and improved materials, techniques, equipment, systems and ocean, atmospheric, and space sciences and related technologies. In fulfillment of this mission, NRL:

* Initiates and conducts broad scientific research of a basic and long-range nature in scientific areas of interest to the Navy.

* Conducts exploratory and advanced technological development deriving from or appropriate to the scientific program areas.

* Within areas of technological expertise, develops prototype systems applicable to specific projects.

* Assumes responsibility as the Navy’s principal R&D activity in areas of unique professional competence upon designation from appropriate Navy or DOD authority.

* Performs scientific research and development for other Navy activities and, where specifically qualified, for other agencies of the Department of Defense and, in defense-related efforts, for other Government agencies.

* Serves as the lead Navy activity for space technology and space systems development and support.

* Serves as the lead Navy activity for mapping, charting, and geodesy (MC&G) research and development for the National Geospatial-Intelligence Agency (NGA).

For more information, please click here

Contacts:

Donna McKinney

202-767-2541

Copyright © Naval Research Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Laboratories

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||