Home > Press > 'Smart skin' simplifies spotting strain in structures: Rice U. invention can use fluorescing carbon nanotubes to reveal stress in aircraft, structures

|

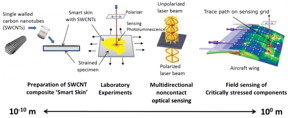

| "Smart skin" able to detect strain in materials, invented at Rice University, starts with carbon nanotubes and their unique ability to change their fluorescence under stress. When attached to a surface, they can be used to monitor stress over time through spectroscopy. CREDIT Satish Nagarajaiah Group/Weisman Research Group/Rice University |

Abstract:

Thanks to one peculiar characteristic of carbon nanotubes, engineers will soon be able to measure the accumulated strain in an airplane, a bridge or a pipeline - or just about anything - over the entire surface or down to microscopic levels.

'Smart skin' simplifies spotting strain in structures: Rice U. invention can use fluorescing carbon nanotubes to reveal stress in aircraft, structures

Houston, TX | Posted on November 15th, 2018They'll do so by shining a light onto structures coated with a two-layer nanotube film and protective polymer. Strain in the surface will show up as changes in the wavelengths of near-infrared light emitted from the film and captured by a miniaturized hand-held reader. The results will show engineers and maintenance crews whether structures like bridges or aircraft have been deformed by stress-inducing events or regular wear and tear.

Like a white shirt under an ultraviolet light, single-wall carbon nanotubes fluoresce, a property discovered in 2002 in the lab of Rice chemist Bruce Weisman. In a basic research project a few years later, the group showed that stretching a nanotube changes the color of its fluorescence.

When Weisman's results came to the attention of Rice civil and environmental engineer Satish Nagarajaiah -- who had been working independently on similar ideas using Raman spectroscopy, but at the macro scale, since 2003 -- he suggested collaborating to turn that scientific phenomenon into a useful technology for strain sensing.

Now, Nagarajaiah and Weisman and have published a pair of important papers about their "smart skin" project. The first appears in Structural Control & Health Monitoring, and introduces the latest iteration of the technology they first revealed in 2012.

It describes a method of depositing the microscopic nanotube-sensing film separately from a protective top layer. Color changes in the nanotube emission indicate the amount of strain in the underlying structure. The researchers say it enables two-dimensional mapping of accumulated strain that can't be achieved by any other non-contact method.

The second paper, in the Journal of Structural Engineering, details the results of testing smart skin on metal specimens with irregularities where stress and strain are often concentrated.

"The project started out as pure science about nanotube spectroscopy, and led to the proof-of-principle collaborative work that showed we could measure the strain of the underlying substrate by checking the spectrum of the film in one place," Weisman said. "That suggested the method could be expanded to measure whole surfaces. What we've shown now is a lot closer to that practical application."

Since the initial report, the researchers have refined the composition and preparation of the film and its airbrush-style application, and also developed scanner devices that automatically capture data from multiple programmed points. Unlike conventional sensors that only measure strain at one point along one axis, the smart film can be selectively probed to reveal strain in any direction and location.

The two-layer film is only a few microns thick, a fraction of the width of a human hair, and barely visible on a transparent surface. "In our initial films, the nanotube sensors were mixed into the polymer," Nagarajaiah said. "Now that we've separated the sensing and the protective layers, the nanotube emission is clearer and we can scan at a much higher resolution. That lets us capture significant amounts of data rather quickly."

The researchers tested smart skin on aluminum bars under tension with either a hole or a notch to represent the places where strain tends to build. Measuring these potential weak spots in their unstressed state and then again after applying stress showed dramatic changes in strain patterns pieced together from point-by-point surface mapping.

"We know where the high-stress regions of the structure are, the potential points of failure," Nagarajaiah said. "We can coat those regions with the film and scan them in the healthy state, and then after an event like an earthquake, go back and re-scan to see whether the strain distribution has changed and the structure is at risk."

In their tests, the researchers said the measured results were a close match to strain patterns obtained through advanced computational simulations. Readings from the smart skin allowed them to quickly spot distinctive patterns near the high-stress regions, Nagarajaiah said. They were also able to see clear boundaries between regions of tensile and compressive strain.

"We measured points 1 millimeter apart, but we can go 20 times smaller when necessary without sacrificing strain sensitivity," Weisman said. That's a leap over standard strain sensors, which only provide readings averaged over several millimeters, he said.

The researchers see their technology making initial inroads in niche applications, like testing turbines in jet engines or structural elements in their development stages. "It's not going to replace all existing technologies for strain measurement right away," Weisman said. "Technologies tend to be very entrenched and have a lot of inertia.

"But it has advantages that will prove useful when other methods can't do the job," he said. "I expect it will find use in engineering research applications, and in the design and testing of structures before they are deployed in the field."

With their smart skin refined, the researchers are working toward developing the next generation of the strain reader, a camera-like device that can capture strain patterns over a large surface all at once.

###

Co-authors of both papers are Rice predoctoral researchers Peng Sun and Ching-Wei Lin and research scientist Sergei Bachilo. Weisman is a professor of chemistry and of materials science and nanoengineering. Nagarajaiah is a professor of civil and environmental engineering, of mechanical engineering, and of materials science and nanoengineering.

The Office of Naval Research and the Welch Foundation supported the research.

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice's undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 2 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance. To read "What they're saying about Rice," go to http://tinyurl.com/RiceUniversityoverview .

Follow Rice News and Media Relations via Twitter @RiceUNews.

For more information, please click here

Contacts:

David Ruth

713-348-6327

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Dual-layer nanotube-based smart skin for enhanced noncontact strain sensing:

Dual-layer nanotube-based smart skin for enhanced noncontact strain sensing:

![]() Noncontact Strain Mapping Using Laser-Induced Fluorescence from Nanotube-Based Smart Skin:

Noncontact Strain Mapping Using Laser-Induced Fluorescence from Nanotube-Based Smart Skin:

![]() Nano-infused paint can detect strain:

Nano-infused paint can detect strain:

![]() Department of Civil and Environmental Engineering:

Department of Civil and Environmental Engineering:

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||