Home > Press > How to mass produce cell-sized robots: Technique from MIT could lead to tiny, self-powered devices for environmental, industrial, or medical monitoring

|

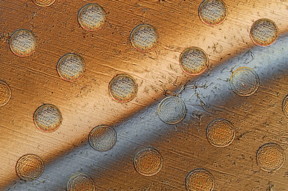

| This photo shows circles on a graphene sheet where the sheet is draped over an array of round posts, creating stresses that will cause these discs to separate from the sheet. The gray bar across the sheet is liquid being used to lift the discs from the surface. Image: Felice Frankel |

Abstract:

Tiny robots no bigger than a cell could be mass-produced using a new method developed by researchers at MIT. The microscopic devices, which the team calls “syncells” (short for synthetic cells), might eventually be used to monitor conditions inside an oil or gas pipeline, or to search out disease while floating through the bloodstream.

How to mass produce cell-sized robots: Technique from MIT could lead to tiny, self-powered devices for environmental, industrial, or medical monitoring

Cambridge, MA | Posted on October 24th, 2018The key to making such tiny devices in large quantities lies in a method the team developed for controlling the natural fracturing process of atomically-thin, brittle materials, directing the fracture lines so that they produce miniscule pockets of a predictable size and shape. Embedded inside these pockets are electronic circuits and materials that can collect, record, and output data.

The novel process, called “autoperforation,” is described in a paper published today in the journal Nature Materials, by MIT Professor Michael Strano, postdoc Pingwei Liu, graduate student Albert Liu, and eight others at MIT.

The system uses a two-dimensional form of carbon called graphene, which forms the outer structure of the tiny syncells. One layer of the material is laid down on a surface, then tiny dots of a polymer material, containing the electronics for the devices, are deposited by a sophisticated laboratory version of an inkjet printer. Then, a second layer of graphene is laid on top.

Controlled fracturing

People think of graphene, an ultrathin but extremely strong material, as being “floppy,” but it is actually brittle, Strano explains. But rather than considering that brittleness a problem, the team figured out that it could be used to their advantage.

“We discovered that you can use the brittleness,” says Strano, who is the Carbon P. Dubbs Professor of Chemical Engineering at MIT. “It's counterintuitive. Before this work, if you told me you could fracture a material to control its shape at the nanoscale, I would have been incredulous.”

But the new system does just that. It controls the fracturing process so that rather than generating random shards of material, like the remains of a broken window, it produces pieces of uniform shape and size. “What we discovered is that you can impose a strain field to cause the fracture to be guided, and you can use that for controlled fabrication,” Strano says.

When the top layer of graphene is placed over the array of polymer dots, which form round pillar shapes, the places where the graphene drapes over the round edges of the pillars form lines of high strain in the material. As Albert Liu describes it, “imagine a tablecloth falling slowly down onto the surface of a circular table. One can very easily visualize the developing circular strain toward the table edges, and that’s very much analogous to what happens when a flat sheet of graphene folds around these printed polymer pillars.”

As a result, the fractures are concentrated right along those boundaries, Strano says. “And then something pretty amazing happens: The graphene will completely fracture, but the fracture will be guided around the periphery of the pillar.” The result is a neat, round piece of graphene that looks as if it had been cleanly cut out by a microscopic hole punch.

Because there are two layers of graphene, above and below the polymer pillars, the two resulting disks adhere at their edges to form something like a tiny pita bread pocket, with the polymer sealed inside. “And the advantage here is that this is essentially a single step,” in contrast to many complex clean-room steps needed by other processes to try to make microscopic robotic devices, Strano says.

The researchers have also shown that other two-dimensional materials in addition to graphene, such as molybdenum disulfide and hexagonal boronitride, work just as well.

Cell-like robots

Ranging in size from that of a human red blood cell, about 10 micrometers across, up to about 10 times that size, these tiny objects “start to look and behave like a living biological cell. In fact, under a microscope, you could probably convince most people that it is a cell,” Strano says.

This work follows up on earlier research by Strano and his students on developing syncells that could gather information about the chemistry or other properties of their surroundings using sensors on their surface, and store the information for later retrieval, for example injecting a swarm of such particles in one end of a pipeline and retrieving them at the other to gain data about conditions inside it. While the new syncells do not yet have as many capabilities as the earlier ones, those were assembled individually, whereas this work demonstrates a way of easily mass-producing such devices.

Apart from the syncells’ potential uses for industrial or biomedical monitoring, the way the tiny devices are made is itself an innovation with great potential, according to Albert Liu. “This general procedure of using controlled fracture as a production method can be extended across many length scales,” he says. “[It could potentially be used with] essentially any 2-D materials of choice, in principle allowing future researchers to tailor these atomically thin surfaces into any desired shape or form for applications in other disciplines.”

This is, Albert Liu says, “one of the only ways available right now to produce stand-alone integrated microelectronics on a large scale” that can function as independent, free-floating devices. Depending on the nature of the electronics inside, the devices could be provided with capabilities for movement, detection of various chemicals or other parameters, and memory storage.

There are a wide range of potential new applications for such cell-sized robotic devices, says Strano, who details many such possible uses in a book he co-authored with Shawn Walsh, an expert at Army Research Laboratories, on the subject, called “Robotic Systems and Autonomous Platforms,” which is being published this month by Elsevier Press.

As a demonstration, the team “wrote” the letters M, I, and T into a memory array within a syncell, which stores the information as varying levels of electrical conductivity. This information can then be “read” using an electrical probe, showing that the material can function as a form of electronic memory into which data can be written, read, and erased at will. It can also retain the data without the need for power, allowing information to be collected at a later time. The researchers have demonstrated that the particles are stable over a period of months even when floating around in water, which is a harsh solvent for electronics, according to Strano.

“I think it opens up a whole new toolkit for micro- and nanofabrication,” he says.

In addition to Strano, Pingwei Liu, who is now at Zhejiang University in China, and Albert Liu, a graduate student in the Strano lab, the team included MIT graduate student Jing Fan Yang, postdocs Daichi Kozawa, Juyao Dong, and Volodomyr Koman, Youngwoo Son PhD ’16, research affiliate Min Hao Wong, and Dartmouth College student Max Saccone and visiting scholar Song Wang. The work was supported by the Air Force Office of Scientific Research, and the Army Research Office through MIT’s Institute for Soldier Nanotechnologies.

###

Written by David L. Chandler, MIT News Office

####

For more information, please click here

Contacts:

Karl-Lydie Jean-Baptiste

MIT News Office

617-253-1682

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() PAPER: Autoperforation of 2D materials for generating two-terminal memristive Janus particles:

PAPER: Autoperforation of 2D materials for generating two-terminal memristive Janus particles:

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

2 Dimensional Materials

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() Closing the gaps — MXene-coating filters can enhance performance and reusability February 28th, 2025

Closing the gaps — MXene-coating filters can enhance performance and reusability February 28th, 2025

Videos/Movies

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Nanofabrication

![]() Self-propelled protein-based nanomotors for enhanced cancer therapy by inducing ferroptosis June 6th, 2025

Self-propelled protein-based nanomotors for enhanced cancer therapy by inducing ferroptosis June 6th, 2025

![]() Multiphoton polymerization: A promising technology for precision medicine February 28th, 2025

Multiphoton polymerization: A promising technology for precision medicine February 28th, 2025

Robotics

![]() Nanofibrous metal oxide semiconductor for sensory face November 8th, 2024

Nanofibrous metal oxide semiconductor for sensory face November 8th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Molecular Machines

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

![]() Nanotech scientists create world's smallest origami bird March 17th, 2021

Nanotech scientists create world's smallest origami bird March 17th, 2021

![]() Giant nanomachine aids the immune system: Theoretical chemistry August 28th, 2020

Giant nanomachine aids the immune system: Theoretical chemistry August 28th, 2020

Molecular Nanotechnology

![]() Quantum pumping in molecular junctions August 16th, 2024

Quantum pumping in molecular junctions August 16th, 2024

![]() Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

Memory Technology

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Nanobiotechnology

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||