Home > Press > Luleċ University of Technology is using the Deben CT5000TEC stage to perform x-ray microtomography experiments with the ZEISS Xradia 510 Versa to understand deformation and strain inside inhomogeneous materials

|

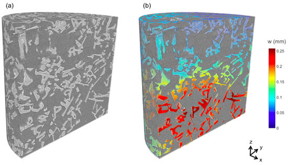

| 3D visualization of snow crystals in bed of fresh snow (a). Quantitative analysis of snow compaction in bed when loaded at 10 N (b). |

Abstract:

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on how Luleċ University of Technology is using their CT5000TEC compression/tensile stage with integrated temperature control to improve the understanding of deformation and strain under different loads and temperatures. This work is being performed in a ZEISS Xradia 510 Versa 3D x-ray microscope.

Luleċ University of Technology is using the Deben CT5000TEC stage to perform x-ray microtomography experiments with the ZEISS Xradia 510 Versa to understand deformation and strain inside inhomogeneous materials

Woolpit, UK | Posted on November 7th, 2017Dr Fredrik Forsberg is an Associate Senior Lecturer in the Department of Engineering Sciences & Mathematics at Luleċ University of Technology (LTU) in Sweden. His research goal at the x-ray microtomography lab is to develop methods and tools that help better understand heterogeneous materials and how they behave in different environments and at different spatial scales.

A new state-of-the-art x-ray microtomography system was installed at LTU in 2016 (John Field Laboratory, E-building). The 3D imaging system, a- Zeiss Xradia 510 Versa, was chosen together with the Deben CT5000TEC in-situ loading module, which allows both mechanical and thermal control, This is the only such system in Sweden. It enables 3D in-situ imaging and characterization of materials including minerals, rocks, metals, composites and wood, with sub-micron resolution. From the acquired 3D data, it is possible to make a quantitative characterization of internal features such as porosity, cracks, grains, fibers, etc., as well as to determine material deformation and strain.

Dr Forsberg describes one of the recent projects using this experimental set up. A recent study, of which we are very proud, is the 3D quantitative in-situ imaging of microscale snow crystals and how they respond to compaction. This study was quite challenging and required a lot of careful planning, but turned out very well. It has received a lot of positive feedback from both the scientific community as well as from media. In matter of fact, the first results from this study were broadcasted on national television (in Sweden) only a few hours after performing the scans. These measurements would have been very hard to achieve without the Deben CT5000TEC stage, since they required precise, simultaneous control of the mechanical load and the temperature (freezing capability).

He continues, describing the results of the project; The snow sample represents fresh snow, acquired only minutes after snowfall. The sample bed was 6 mm in diameter and 5 mm in height (initially). The scans were carried out using a spatial resolution of 4.0 micron. The in situ loading was carried out using the Deben CT5000TEC load stage with a 500 N load cell. Four XMT scans were acquired along the load cycle 0N-10N-18N-25N, at a constant temperature of -15 °C. Quantitative analysis of microstructure (shape of crystals, porosity, etc.) was obtained from 3D image analysis, using the software Dragonfly Pro (ORS), and the compaction of the snow bed was analyzed by digital volume correlation (DVC), using software from LaVision.

Finally, Dr Forsberg gives his conclusions about the value of this technique. X-ray microtomography and digital volume correlation allows us to perform quantitative in-situ studies of snow compaction. Also, these tools allow us to study the compaction process at multiple spatial scales global phenomena and grain-to-grain interactions. X-ray microtomography and the use of the Deben load stage with temperature control allows studies of snow crystal microstructure in a way that until recently has not been possible. Previously, we have mainly used test stages that we have built ourselves. However, none of these have had temperature control. A further great benefit in using the Deben stage is the flexibility in using different load cells which may be selected depending on material and application. Also, the software interface is easy to use and is supported by the Scout and Scan software from Zeiss that is used for control of the Versa.

More information about this and other projects from Dr Forsberg's laboratory may be found at their web site. Click here. To obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk. Note: for a high resolution copy of the image, either right click to download or contact Jezz Leckenby at Talking Science.

####

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.

For more information, please click here

Contacts:

Deben UK Limited

Brickfields Business Park

Old Stowmarket Road

Woolpit, Bury St Edmunds

Suffolk IP30 9QS, UK

T +44 (0)1359 244870

www.deben.co.uk

Talking Science Limited

39 de Bohun Court

Saffron Walden

Essex CB10 2BA

T +44(0)1799 521881

M +44(0)7843 012997

www.talking-science.com

Copyright © Deben

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Imaging

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

![]() Observation of left and right at nanoscale with optical force October 6th, 2023

Observation of left and right at nanoscale with optical force October 6th, 2023

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the worlds smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the worlds smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Announcements

![]() NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navys quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||