Home > Press > Conformal transfer of graphene for reproducible device fabrication

|

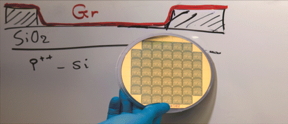

| Reliable wafer scale production of graphene devices. |

Abstract:

Conformal transfer of graphene on a prepatterned substrate is a viable technology for reproducible fabrication of graphene devices. Such is the conclusion of a recent study by a team of scientists from Germany, the Netherlands, Spain and Saudi Arabia.

Conformal transfer of graphene for reproducible device fabrication

San Sebastian, Spain | Posted on August 11th, 2015Reliable fabrication of graphene devices for electronics has been a technological challenge for the graphene community for years. Large area high quality graphene, required for high-tech applications, is typically grown by chemical vapor deposition (CVD) on metal foils. Following growth, the graphene film is transferred to an electronically useful substrate, which is commonly SiO2 on Si. Standard procedure follows these steps up with photolithographic patterning of devices and evaporation of gold contacts.

In the past, this sequence of steps failed to result in devices of consistently high quality, as each fabrication step introduced unpredictable defects. The film growth was the first step to be perfected by a global network of busy scientists. Graphene transfer was in parallel mastered by the Spanish company Graphenea, a participant of this most recent breakthrough, as evidenced by their patent award earlier this year. Still, lithography and evaporation would cause film breaks, cracks and wrinkles, which were unpredictable and which lowered the quality of the final devices. Now, researchers have turned the fabrication upside down by performing lithography and contact evaporation prior to graphene transfer. The result is a reliable method for wafer-scale fabrication of graphene devices.

The paper, recently published in Applied Materials & Interfaces (a publication of the American Chemical Society), starts by considering the values reported in literature for contact and sheet resistance obtained with the standard graphene fabrication and transfer method. Focusing on graphene grown by CVD, the researchers find that there is significant scatter in the reported values, spanning nearly an order of magnitude. The scientists then performed the standard procedure themselves, finding that the resulting graphene sheet is inhomogeneous, with defects appearing in random places.

Following the improved process, in which the contact patterning and metal deposition are performed prior to the transfer, yields a much better result. The graphene sheet is smooth and uniform across the wafer, conformally covering the electrode structures. Electrical measurements indicate good device reproducibility, with sheet resistance low enough to consider using these graphene devices in radio frequency electronics. The potential application of the graphene channels is additionally confirmed by steady device performance over a wide range of applied current, up to 0.5 A. The careful fabrication led to devices that support the highest current density ever reported in transferred CVD graphene.

Over 600 devices were tested, showing a very narrow spread in the measured parameters. Such statistical similarity not only opens a gate to mass production of graphene devices for radio frequency applications, but immediately allows the testing of fundamental device physics of monolayer materials.

####

For more information, please click here

Contacts:

Headquarters

Graphenea

Avenida de Tolosa, 76

20018 - Donostia/San Sebastián

Spain

Copyright © Graphenea Inc.

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Patents/IP/Tech Transfer/Licensing

![]() Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

![]() Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

![]() Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

New-Contracts/Sales/Customers

![]() Bruker Light-Sheet Microscopes at Major Comprehensive Cancer Center: New Advanced Imaging Center Powered by Two MuVi and LCS SPIM Microscopes March 25th, 2021

Bruker Light-Sheet Microscopes at Major Comprehensive Cancer Center: New Advanced Imaging Center Powered by Two MuVi and LCS SPIM Microscopes March 25th, 2021

![]() Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

![]() Veeco Announces Aledia Order of 300mm MOCVD Equipment for microLED Displays: Propel™ Platform First 300mm System with EFEM Designed for Advanced Display Applications October 20th, 2020

Veeco Announces Aledia Order of 300mm MOCVD Equipment for microLED Displays: Propel™ Platform First 300mm System with EFEM Designed for Advanced Display Applications October 20th, 2020

![]() GREENWAVES TECHNOLOGIES Announces Next Generation GAP9 Hearables Platform Using GLOBALFOUNDRIES 22FDX Solution October 16th, 2020

GREENWAVES TECHNOLOGIES Announces Next Generation GAP9 Hearables Platform Using GLOBALFOUNDRIES 22FDX Solution October 16th, 2020

RFID

![]() Nanowire 'inks' enable paper-based printable electronics: Highly conductive films make functional circuits without adding high heat January 4th, 2017

Nanowire 'inks' enable paper-based printable electronics: Highly conductive films make functional circuits without adding high heat January 4th, 2017

![]() Designer electronics out of the printer: Optimized printing process enables custom organic electronics June 16th, 2015

Designer electronics out of the printer: Optimized printing process enables custom organic electronics June 16th, 2015

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||