Home > Press > Stanford makes flexible carbon nanotube circuits more reliable and power efficient: Engineers invent a process to 'dope' carbon filaments with an additive to improve their electronic performance, paving the way for digital devices that bend

|

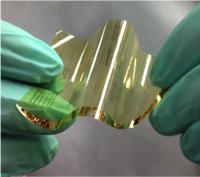

| Stanford engineers have developed an improved process for making flexible circuits that use carbon nanotube transistors, a development that paves the way for a new generation of bendable electronic devices.

Credit: Bao Lab, Stanford University |

Abstract:

Engineers would love to create flexible electronic devices, such as e-readers that could be folded to fit into a pocket. One approach they are trying involves designing circuits based on electronic fibers, known as carbon nanotubes (CNTs), instead of rigid silicon chips.

Stanford makes flexible carbon nanotube circuits more reliable and power efficient: Engineers invent a process to 'dope' carbon filaments with an additive to improve their electronic performance, paving the way for digital devices that bend

Stanford, CA | Posted on March 18th, 2014But reliability is essential. Most silicon chips are based on a type of circuit design that allows them to function flawlessly even when the device experiences power fluctuations. However, it is much more challenging to do so with CNT circuits.

Now a team at Stanford has developed a process to create flexible chips that can tolerate power fluctuations in much the same way as silicon circuitry.

"This is the first time anyone has designed a flexible CNT circuits that have both high immunity to electrical noise and low power consumption, " said Zhenan Bao, a professor of chemical engineering at Stanford with a courtesy appointment in Chemistry and Materials Science and Engineering.

The group reported its findings in the Proceedings of the National Academy of Sciences. Huiliang (Evan) Wang, a graduate student in Bao's lab, and Peng Wei, a previous postdoc in Bao's lab, were the lead authors of the paper. Bao's team also included Yi Cui, an associate professor of materials science at Stanford, and Hye Ryoung Lee, a graduate student in his lab.

In principle, CNTs should be ideal for making flexible electronic circuitry. These ultra thin carbon filaments have the physical strength to take the wear and tear of bending, and the electrical conductivity to perform any electronic task.

But until this recent work from the Stanford team, flexible CNTs circuits didn't have the reliability and power-efficiency of rigid silicon chips.

Here's the reason. Over time, engineers have discovered that electricity can travel through semiconductors in two different ways. It can jump from positive hole to positive hole, or it can push through a bunch of negative electronic like a beaded necklace. The first type of semiconductor is called a P-type, the second is called and N-type.

Most importantly, engineers discovered that circuits based on a combination of P-type and N-type transistors perform reliably even when power fluctuations occur, and they also consume much less power. This type of circuit with both P-type and N-type transistors is called complementary circuit. Over the last 50 years engineers have become adept at creating this ideal blend of conductive pathways by changing the atomic structure of silicon through the addition of minute amounts of useful substances - a process called "doping" that is conceptually akin to what our ancestors did thousands of years ago when they stirred tin into molten copper to create bronze.

The challenge facing the Stanford team was that CNTs are predominately P-type semiconductors and there was no easy way to dope these carbon filaments to add N-type characteristics.

The PNAS paper explains how the Stanford engineers overcame this challenge. They treated CNTs with a chemical dopant they developed known as DMBI, and they used an inkjet printer to deposit this substance in precise locations on the circuit.

This marked the first time any flexible CNT circuit has been doped to create a P-N blend that can operate reliably despite power fluctuations and with low power consumption.

The Stanford process also has some potential application to rigid CNTs. Although other engineers have previously doped rigid CNTs to create this immunity to electrical noise, the precise and finely tuned Stanford process out performs these prior efforts, suggesting that it could be useful for both flexible and rigid CNT circuitry.

Bao has focused her research on flexible CNTs, which compete with other experimental materials, such as specially formulated plastics, to become the foundation for bendable electronics, just as silicon has been the basis for rigid electronics.

As a relatively new material, CNTs are playing catch up to plastics, which are closer to mass market use for such things as bendable display screens. The Stanford doping process moves flexible CNTs closer toward commercialization because it shows how to create the P-N blend, and the resultant improvements in reliability and power consumption, already present in plastic circuits.

Although much work lies ahead to make CNTs commercial, Bao believes these carbon filaments are the future of flexible electronics, because they are strong enough to bend and stretch, while also being capable of delivering faster performance than plastic circuitry.

"CNTs offer the best long term electronic and physical attributes," Bao said.

####

For more information, please click here

Contacts:

Tom Abate

650-736-2245

Copyright © Stanford School of Engineering

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Flexible Electronics

![]() CityU awarded invention: Soft, ultrathin photonic material cools down wearable electronic devices June 30th, 2023

CityU awarded invention: Soft, ultrathin photonic material cools down wearable electronic devices June 30th, 2023

![]() Liquid metal sticks to surfaces without a binding agent June 9th, 2023

Liquid metal sticks to surfaces without a binding agent June 9th, 2023

![]() Breaking through the limits of stretchable semiconductors with molecular brakes that harness light June 9th, 2023

Breaking through the limits of stretchable semiconductors with molecular brakes that harness light June 9th, 2023

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||