Home > Press > “Waviness” Explains Why Carbon Nanotube Forests Have Low Stiffness

|

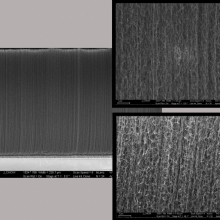

| This montage includes images of carbon nanotube forests. New research explains why the CNT forests have less stiffness than expected. Images courtesy of Justin Chow |

Abstract:

A new study has found that "waviness" in forests of vertically-aligned carbon nanotubes dramatically reduces their stiffness, answering a long-standing question surrounding the tiny structures. Instead of being a detriment, the waviness may make the nanotube arrays more compliant and therefore useful as thermal interface material for conducting heat away from future high-powered integrated circuits.

“Waviness” Explains Why Carbon Nanotube Forests Have Low Stiffness

Atlanta, GA | Posted on October 1st, 2013Measurements of nanotube stiffness, which is influenced by a property known as modulus, had suggested that forests of vertically-aligned nanotubes should have a much higher stiffness than what scientists were actually measuring. The reduced effective modulus had been blamed on uneven growth density, and on buckling of the nanotubes under compression.

However, based on experiments, scanning electron microscope (SEM) imaging and mathematical modeling, the new study found that kinked sections of nanotubes may be the primary mechanism reducing the modulus.

"We believe that the mechanism making these nanotubes more compliant is a tiny kinkiness in their structure," said Suresh Sitaraman, a professor in the Woodruff School of Mechanical Engineering at the Georgia Institute of Technology. "Although they appear to be perfectly straight, under high magnification we found waviness in the carbon nanotubes that we believe accounts for the difference in what is measured versus what would be expected."

The research, which was supported by the Defense Advanced Research Projects Agency (DARPA), was published online August 31, 2013, in the journal Carbon. It will appear later in the journal's print issue.

Carbon nanotubes provide many attractive properties, including high electrical and thermal conductivity, and high strength. Individual carbon nanotubes have a modulus ranging from 100 gigapascals to 1.5 terapascals. Arrays of vertically-aligned carbon nanotubes with a low density would be expected to a have an effective modulus of at least five to 150 gigapascals, Sitaraman said, but scientists have typically measured values that are four orders or magnitude less - between one and 10 megapascals.

To understand what might be causing this variation, Sitaraman and Ph.D. students Nicholas Ginga and Wei Chen studied forests of carbon nanotubes grown atop a silicon substrate, then covered the tips of the structures with another layer of silicon. They then used sensitive test apparatus - a nanoindenter - to compress samples of the nanotubes and measure their stiffness. Alternately, they also placed samples of the silicon-nanotube sandwiches under tensile stress - pulling them apart instead of compressing them.

What they found was that the effective modulus remained low - as much as 10,000 times less than expected - regardless of whether the nanotube sandwiches were compressed or pulled apart. That suggests growth issues, or buckling, could not fully account for the differences observed.

To look for potential explanations, the researchers examined the carbon nanotubes using scanning electron microscopes located in Georgia Tech's Institute for Electronics and Nanotechnology facilities. At magnification of 10,000 times, they saw the waviness in sections of the nanotubes.

"We found very tiny kinks in the carbon nanotubes," said Sitaraman. "Although they appeared to be perfectly straight, there was waviness in them. The more waviness we saw, the lower their stiffness was."

They also noted that under compression, the nanotubes contact one another, influencing nanotube behavior. These observations were modeled mathematically to help explain what was being seen across the different conditions studied.

"We took into account the contact between the carbon nanotubes," said Chen. "This allowed us to investigate the extreme conditions under which the deformation of nanotubes is constrained by the presence of neighboring nanotubes in the forest."

Though the loss of modulus might seem like a problem, it actually may be helpful in thermal management applications, Sitaraman said. The compliance of the nanotubes allows them to connect to a silicon integrated circuit on one side, and be bonded to a copper heat spreader on the other side. The flexibility of the nanotubes allows them to move as the top and bottom structures expand and contract at different rates due to temperature changes.

"The beauty of the carbon nanotubes is that they act like springs between the silicon chip and the copper heat spreader," said Sitaraman. "They can conduct lots of heat because of good thermal properties, and at the same time, they are supple and compliant."

Carbon nanotubes have extraordinarily high thermal conductivity, as much as ten times that of copper, making them ideal for drawing heat away from the chips.

"The demand for heat removal from chips is continuing to increase," said Ginga. "Industry has been looking for new materials and new techniques to add to their toolbox for heat transfer. Different approaches will be needed for different devices, and this provides the industry with a new way to address the challenge."

####

For more information, please click here

Contacts:

Research News

Georgia Institute of Technology

177 North Avenue

Atlanta, Georgia 30332-0181 USA

John Toon

404-894-6986

or

Brett Israel

404-385-1933

Copyright © Georgia Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||