Home > Press > "Watermark Ink" device identifies unknown liquids instantly: New 3D-nanostructured chip offers a litmus test for surface tension (and doubles as a carrier for secret messages)

|

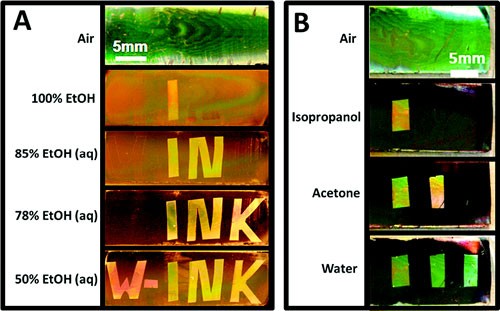

| The "W-Ink" technology has only become possible due to a seamless fusion and interaction between chemistry, optics, condensed matter, and fluidics. (A) In the prototype device discussed in JACS, the chip appears blank in the air. When dipped in varying concentrations of ethanol, however, it reveals new markings. (B) Because all liquids exhibit a surface tension, this indicator has the potential to be used to differentiate between liquids of any type. (Image courtesy of Ian Burgess.) |

Abstract:

Materials scientists and applied physicists collaborating at Harvard's School of Engineering and Applied Sciences (SEAS) have invented a new device that can instantly identify an unknown liquid.

The researchers used "secret messages" to demonstrate how each chip can be customized to recognize particular substances and respond differently to each one. In the presence of water, these chips display a decoy message: "Ω Δ Π / 507." Only when swabbed with 77% ethanol (top chip) and 100% ethanol (bottom chip) will the true message be displayed: "MAT SCI"—short for "materials science."

"Watermark Ink" device identifies unknown liquids instantly: New 3D-nanostructured chip offers a litmus test for surface tension (and doubles as a carrier for secret messages)

Cambridge, MA | Posted on August 4th, 2011The device, which fits in the palm of a hand and requires no power source, exploits the chemical and optical properties of precisely nanostructured materials to distinguish liquids by their surface tension.

The finding, published in the Journal of the American Chemical Society (JACS), offers a cheap, fast, and portable way to perform quality control tests and diagnose liquid contaminants in the field.

"Digital encryption and sensors have become extremely sophisticated these days, but this is a tool that will work anywhere, without extra equipment, and with a very wide range of potential applications," says co-principal investigator Marko Lončar, Associate Professor of Electrical Engineering at SEAS.

Akin to the litmus paper used in chemistry labs around the world to detect the pH of a liquid, the new device changes color when it encounters a liquid with a particular surface tension. A single chip can react differently to a wide range of substances; it is also sensitive enough to distinguish between two very closely related liquids.

A hidden message can actually be "written" on a chip, revealing itself only when exposed to exactly the right substance. Dipped in another substance, the chip can display a different message altogether (see video below).

"This highly selective wetting would be very difficult to achieve on a two-dimensional surface," explains lead author Ian B. Burgess, a doctoral candidate in Lončar's lab and in the Aizenberg Biomineralization and Biomimetics Lab. "The optical and fluidic properties we exploit here are unique to the 3D nanostructure of the material."

The "Watermark Ink," or "W-Ink," concept relies on a precisely fabricated material called an inverse opal. The inverse opal is a layered glass structure with an internal network of ordered, interconnected air pores.

Co-authors Lidiya Mishchenko (a graduate student at SEAS) and Benjamin D. Hatton (a research appointee at SEAS and a technology development fellow at the Wyss Institute for Biologically Inspired Engineering at Harvard), recently perfected the production process of large-scale, highly ordered inverse opals.

"Two factors determine whether the color changes upon the introduction of a liquid: the surface chemistry and the degree of order in the pore structure," says Mishchenko, who works in the Aizenberg lab. "The more ordered the structure, the more control you can have over whether or not the liquid enters certain pores by just changing their surface chemistry."

Burgess and his colleagues discovered that selectively treating parts of the inverse opal with vaporized chemicals and oxygen plasma creates variations in the reactive properties of the pores and channels, letting certain liquids pass through while excluding others.

Allowing liquid into a pore changes the material's optical properties, so the natural color of the inverse opal shows up only in the dry regions.

Each chip is calibrated to recognize only certain liquids, but it can be used over and over (provided the liquid evaporates between tests).

With the hope of commercializing the W-Ink technology, the researchers are currently developing more precisely calibrated chips and conducting field tests with government partners for applications in quality assurance and contaminant identification.

"If you want to detect forgeries," says Burgess, "you can tune your sensor to be acutely sensitive to one specific formulation, and then anything that's different stands out, regardless of the composition."

One immediate application would allow authorities to verify the fuel grade of gasoline right at the pump. Burgess also envisions creating a chip that tests bootleg liquor for toxic levels of methanol.

The W-Ink technology would additionally be useful for identifying chemical spills very quickly. A W-Ink chip that was calibrated to recognize a range of toxic substances could be used to determine, on the spot, whether the spill required special treatment.

"A device like this is not going to rival the selectivity of GC-MS [gas chromatography-mass spectrometry]," remarks co-principal investigator Joanna Aizenberg, the Amy Smith Berylson Professor of Materials Science at SEAS and a core faculty member of the Wyss Institute.

"But the point is that if you want something in the field that requires no power, is easy to use, and gives you an instant result, then the W-Ink may be what you need."

Aizenberg is also the Susan S. and Kenneth L. Wallach Professor at the Radcliffe Institute for Advanced Study; Professor of Chemistry and Chemical Biology at Harvard; and Co-Director of the Kavli Institute for Bionano Science and Technology at Harvard.

Burgess, Mishchenko, Hatton, Lončar, and Aizenberg were joined on the paper by co-author Mathias Kolle, a postdoctoral researcher in Aizenberg's lab.

###

The "W-Ink" research was supported by grants from:

the Air Force Office of Scientific Research;

the Natural Sciences and Engineering Research Council of Canada; and

the U.S. Department of Homeland Security (DHS), administered by the Oak Ridge Institute for Science and Education, through an interagency agreement between the U.S. Department of Energy and DHS.

Electron microscopy was performed at Harvard's Center for Nanoscale Systems, part of the National Nanotechnology Infrastructure Network, which is supported by the National Science Foundation.

####

For more information, please click here

Contacts:

Caroline Perry

(617) 496-1351

Copyright © Harvard's School of Engineering and Applied Sciences (SEAS)

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Chemistry

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Imaging

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||