Home > Press > Nanotechnology Students Make World's Smallest Images of Stephen Colbert

|

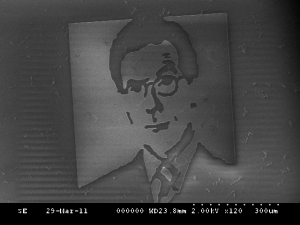

| The smallest likeness of Stephen Colbert in the world, "Micro Colbert". Four micro sized images of Stephen were fabricated in a clean room environment on a silicon wafer by two nanotech undergrad students at the University of Waterloo. |

Abstract:

The world's smallest images of Stephen Colbert were made by two undergraduate nanotechnology engineering students. John Maier and Erin Bedford fabricated four micro sized images of Stephen Colbert in a clean room at the University of Waterloo.

Nanotechnology Students Make World's Smallest Images of Stephen Colbert

Waterloo, Canada | Posted on April 6th, 2011The world's smallest images of Stephen Colbert were made by two undergraduate nanotechnology engineering students. The students, John Maier and Erin Bedford, fabricated four micro sized images of Stephen Colbert (www.microcolbert.com). The two students are graduating from the Nanotechnology Engineering program at the University of Waterloo. The smallest of the four images measured approximately 110μm by 130μm, while the largest measured 1.8mm by 2.3mm. The smallest feature size on the smallest image measured approximately 400nm across. Images were captured of each Colbert image using a Scanning Electron Microscope (SEM). The Micro Colbert images were made from a micrometer thin layer of aluminum that was sputtered on to the substrate through a photoresist pattern.

A layer of chrome metal was deposited on a blank wafer followed by a silicon nitride (SiN) layer, grown using plasma-enhanced chemical vapor deposition (PECVD). The SiN layer was then dry etched using reactive-ion etching (RIE). A layer of aluminum was then deposited on the wafer using sputtering and treated, completing the wafer fabrication. Lithography techniques were used throughout the process to generate the designed patterns.

John Maier (www.johnmaier.com) and Erin Bedford (ca.linkedin.com/pub/erin-bedford/16/2b4/614) are part of the second graduating class of the new Nanotechnology Engineering program at the University of Waterloo. "Hopefully Stephen will cover it on the show and help to get kids excited about nanotechnology," John said. During the course of their co-op degree, Erin has interned at the University of Albany, Xerox Research Center of Canada and EMPA in Switzerland. John has interned at Broadcom Corporation, the National Research Council of Canada and Facebook.

For more information on Micro Colbert please visit the website www.microcolbert.com, or follow the pages on Facebook or Twitter.

####

For more information, please click here

Contacts:

John Maier

Copyright © John Maier

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Imaging

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Human Interest/Art

![]() New 2D multifractal tools delve into Pollock's expressionism January 17th, 2025

New 2D multifractal tools delve into Pollock's expressionism January 17th, 2025

![]() Drawing data in nanometer scale September 30th, 2022

Drawing data in nanometer scale September 30th, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Graphene nanotubes revolutionize touch screen use for prosthetic hands August 3rd, 2021

Graphene nanotubes revolutionize touch screen use for prosthetic hands August 3rd, 2021

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||