Home > Press > Manufacturing microspheres: Technique mass-produces uniform, encapsulated particles for pharmaceuticals, many other uses

|

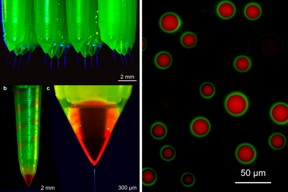

| The emitters that produce the microspheres have two openings — a hole and a concentric ring, each fed by separate microfluidic channels. Under precisely calibrated conditions, the material drawn through the outer ring encases the material drawn through the center hole, creating an encapsulated particle.

Courtesy of the researchers |

Abstract:

Microencapsulation, in which a tiny particle of one material is encased within a shell made from another, is widely used in pharmaceuticals manufacturing and holds promise for other areas, such as self-repairing materials and solar power.

Manufacturing microspheres: Technique mass-produces uniform, encapsulated particles for pharmaceuticals, many other uses

Cambridge, MA | Posted on October 6th, 2016But most applications of microencapsulation require particles of uniform size, and that’s something that existing fabrication techniques don’t reliably provide. In products with a high profit margin, such as pharmaceuticals, it can be cost effective to mechanically separate particles of the proper size from those that are too large or too small, but in niche or small-margin products, it may not be.

In the latest issue of the journal Lab on a Chip, researchers from MIT’s Microsystems Technology Laboratories report a new microencapsulation technique that yields particles of very consistent size, while also affording a high rate of production.

Moreover, the devices used to produce the spheres were themselves manufactured with an affordable commercial 3-D printer. The ability to 3-D print fabrication systems would not only keep manufacturing costs low but also allow researchers to quickly develop systems for producing microencapsulated particles for particular applications.

“When you print your microsystems, you can iterate them very fast,” says Luis Fernando Velásquez-García, a principal research scientist in the Microsystems Technology Laboratories and senior author on the new paper. “In one year, we were able to make three different generations that are significantly different from one another and that in terms of performance also improve significantly. Something like that would be too expensive and too time consuming with other methods.”

Velásquez-García is joined on the paper by Daniel Olvera-Trejo, a postdoc at Mexico’s Tecnológico de Monterrey who was a visiting researcher at MIT under the auspices of a new nanoscience research partnership between the two universities.

Concentric circles

The researchers’ new system adapts the same core technology that Velásquez-García’s group has previously explored as a means for depositing material on chip surfaces, etching chips, generating X-rays, spinning out nanofibers for use in a huge range of applications, and even propelling nanosatellites.

All of these applications rely on dense arrays of emitters that eject fluids, electrons, or streams of ions. The emitters might be conical, cylindrical, or rectangular; etched microscopically or 3-D printed; hollow, like nozzles, or solid. But in all instances, Velásquez-García’s group has used electric fields — rather than, say, microfluidic pumps — to control their emissions.

The new emitters are a variant on the hollow 3-D-printed design. But instead of having a single opening at its tip, each emitter has two openings — a hole and a concentric ring. The openings are fed by separate microfluidic channels. If the viscosity and electrical conductivity of the fluids fed through the channels, the strength of the electric field that draws them up, and the length and diameter of the channels are precisely calibrated, the emitters will produce tiny spheres in which the material drawn through the outer ring encases the material drawn through the center hole.

According to Velásquez-García, the physics describing the relationship of forces that produces the microcapsules is only around a decade old. Other researchers have built individual emitters that can produce microcapsules, but Velásquez-García’s group is the first to arrange the emitters in a monolithic array — 25 emitters packed onto a chip that’s less than an inch square — while maintaining both efficiency and uniformity. The arrays are also modular in design, so they can be tiled together to produce larger arrays.

Pharmaceuticals manufacturers use microencapsulation to protect drugs from degradation before they reach their targets. But researchers have also explored microencapsulation as a way to make self-healing materials: The same stress that causes a material to crack would break the capsules, releasing an epoxy that would patch the crack. There, uniformity of capsule size is crucial to ensure that distributing the capsules throughout the material doesn’t compromise its structural integrity.

Dye-sensitized solar cells, another potential application for the new technique, are potentially a cheap alternative to silicon solar cells. They use tiny particles of dye-coated metal suspended in some other material, often a fluid. The dye converts light to electricity, which the metal transmits to electrodes. Preserving an exact ratio of dye-covered surface area to volume of metal maximizes the efficiency of the cell.

Printing possibilities

In their initial experiments, Velásquez-García and Olvera-Trejo used water and sesame oil as their fluids, and the emitters were made from plastic. The resulting microspheres were around 25 micrometers in diameter. There are, however, 3-D printers that use metal or ceramics, which could produce emitters able to tolerate hotter or harsher fluids.

To pack the emitter arrays into the smallest possible volume, the researchers used helical fluid channels, which spiral around the interiors of the emitters, minimizing their height. To control the rate of emission, the channels also taper, from 0.7 millimeters at their bases to 0.4 mm at their tips. Such small and complex devices would be virtually impossible to manufacture using standard microfabrication processes, Velásquez-García says.

“These devices can only be made if you print them,” Velásquez-García says. “We’re not doing printing because we can. We’re doing printing because it enables something that didn’t exist before that brings very exciting possibilities.”

###

Written by Larry Hardesty, MIT News Office

####

For more information, please click here

Contacts:

Abby Abazorius

MIT News Office

617.253.2709

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Self-repairing Materials

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

![]() Materials scientists learn how to make liquid crystal shape-shift September 25th, 2020

Materials scientists learn how to make liquid crystal shape-shift September 25th, 2020

![]() Self-driving microrobots December 10th, 2019

Self-driving microrobots December 10th, 2019

![]() Disruptive by Design: Nano Now February 1st, 2019

Disruptive by Design: Nano Now February 1st, 2019

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

MEMS

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||