Home > Press > How 'transparent' is graphene? MIT researchers find that adding a coating of graphene has little effect on how a surface interacts with liquids - except in extreme cases

|

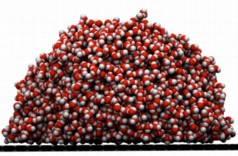

| A simulated water droplet on a sheet of suspended graphene. Image: Chih-Jen Shih |

Abstract:

The amazing electrical, optical and strength properties of graphene, a single-atom-thick layer of carbon, have been extensively researched over the last decade. Recently, the material has been studied as a coating that might confer electrical conductivity while maintaining other properties of the underlying material.

How 'transparent' is graphene? MIT researchers find that adding a coating of graphene has little effect on how a surface interacts with liquids - except in extreme cases

Cambridge, MA | Posted on December 3rd, 2012But the "transparency" of such a graphene coating to wetting — a measure of the degree to which liquids spread out or bead up on a surface — is not as absolute as some researchers had thought. New research at MIT shows that for materials with intermediate wettability, graphene does preserve the properties of the underlying material. But for more extreme cases — superhydrophobic surfaces, which intensely repel water, or superhydrophilic ones, which cause water to spread out — an added layer of graphene does significantly change the way coated materials behave.

That's important, because these extreme cases are generally of greatest interest. For example, coating a superhydrophobic material with graphene was seen as a possible way of making electronic circuits that would be protected from short-circuiting and corrosion in water. But it's not quite that simple, the new research shows.

The findings were recently published in the journal Physical Review Letters by professors Daniel Blankschtein and Michael Strano, graduate student Chih-Jeh Shih, and three other MIT postdocs and students.

Blankschtein, the Herman P. Meissner '29 Professor of Chemical Engineering, has studied wetting properties for a long time. He had not previously examined graphene, but decided to explore its wettability now that it's a material of great interest to researchers.

Because graphene's transparency to wettability turned out not to be perfect, Blankschtein says, "this finding may be viewed as a negative result." But, he adds, "it is nevertheless extremely important to the scientific community, because it [shows] what can actually be accomplished in practice."

Most electrically conductive materials, he points out, are hydrophilic: Water spreads readily on them, thoroughly wetting the surface. "On the other hand," he says, "for many electronic and military applications, it is important to fabricate hydrophobic, electrically conductive surfaces." And while graphene's transparency to wettability is not perfect, it may still be good enough for such applications, he says.

This research, which included both theoretical modeling and experimental confirmation, shows that by depositing a large graphene sheet, grown by a process called chemical vapor deposition, on another material's surface, "it would be possible to induce electrical conductivity on the surface, while partially preserving the desired surface wetting behavior," Blankschtein says. In fact, he adds, the contact angle of such a surface — the measure of how well it prevents wetting — "is believed to be one of the highest attainable on a flat, electrically conductive surface to date."

Shih, the lead author of the paper, says, "We have demonstrated that the wettability of a transparent, graphene-coated surface can be manipulated without undermining its thermal/electrical conductivity." That's useful because "in general, conductive surfaces have very high wettability due to their high surface tension, and it is generally very challenging to produce a thermally/electrically conductive surface with tunable wettability" — wettability that can be controlled almost at will.

The team describes this partial transmission of the underlying characteristics as "translucency," rather than transparency, of wettability.

By selecting a particular combination of an underlying material with a graphene coating, different combinations of electrical, optical and wetting characteristics can be achieved, Shih says: "People can control the wetting properties of the substrate … this breakthrough successfully decouples the conductivity and wettability of a material."

What's more, this opens up new possibilities for practical devices, because the materials involved are already widely used in industry, Shih says: "Due to its compatibility with today's semiconductor processes, many exciting opportunities may be pursued in the areas of microelectronics, nanoscale heat transfer and microfluidic devices — to simultaneously engineer desired wettability, heat transfer and electronic transport."

Blankschtein emphasizes that in addition to the potential applications, "I'm excited about this from a fundamental point of view." It shows, he says, that "you can't assume that you can just take a substrate and drop graphene on it without perturbing the wetting behavior." By understanding this complex behavior, "we can learn how to take advantage of that."

The work, which also involved MIT postdocs Qing Hua Wang, Shangchao Lin and Zhong Jin and graduate student Kyoo-Chul Park, was supported by the Office of Naval Research, the National Science Foundation and MIT's Institute for Soldier Nanotechnology.

####

For more information, please click here

Contacts:

Caroline McCall

MIT Media Relations

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Microfluidics/Nanofluidics

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||