Home > Nanotechnology Columns > NanoGlobe > Nanoimprint Lithography Enabling NanoManufacturing - Singapore's Initiative in Industrial Consortium on Nanoimprint (I.C.O.N.) led by the Institute of Materials Research and Engineering (IMRE)

|

NanoGlobe Pte Ltd Nanotechnology Business Development Consultants NanoGlobe Pte Ltd |

Abstract:

Nanoimprint Lithography (NIL) being simple thus low cost has attracted increasing attention from industrial players. This has motivated NIL group in IMRE, led by Dr Low Hong Yee, to form Industrial Consortium on Nanoimprint (I.C.O.N.) to further promote and accelerate the adoption of NIL in industry manufacturing. I.C.O.N. was successfully launched together with the 4th Industrial Symposium on Nanoimprint Lithography (NIL) on 3rd August 2010. In this article, we share a brief overview about I.C.O.N. and highlight the NIL capability of IMRE presented during the industrial symposium.

August 31st, 2010

Nanoimprint Lithography Enabling NanoManufacturing - Singapore's Initiative in Industrial Consortium on Nanoimprint (I.C.O.N.) led by the Institute of Materials Research and Engineering (IMRE)

Creating nanopattern on substrate surfaces to obtain certain functionality without additional materials is one significant capability of nanoimprint lithography (NIL). Although it is originally invented for semiconductor and data storage industries, nowadays NIL has been receiving more attentions from wider range of industries including consumer electronics, health care, food packaging, solar, MEMS/NEMS, as well as aerospace and automotives. Singapore Institute of Materials Research and Engineering (IMRE) has established itself as one of the world leaders in progressing NIL technology, under the leadership of Dr Low Hong Yee, for wide industrial adoption. Propelled by the increasing number of industry players interested in NIL and potential converging themes for industries to work together, Industrial Consortium on Nanoimprint (I.C.O.N.) was finally formed by IMRE and supported by the governmental agencies (Singapore EDB, SPRING Singapore, and IE Singapore). It was launched in conjunction with the 4th Industrial Symposium on Nanoimprint Lithography on 3rd August 2010. As part of nanomanufacturing enabling technology, I.C.O.N. will focus on nanostructuring for nanosurfaces, explained by Dr Low.

The launch was marked by the signing of project agreement by the consortium project partners, which, in addition to IMRE, consists of Institute of High Performance Computing (IHPC), DSO National Laboratories, Solves Innovative Technology Pte Ltd (all of which are Singapore entities), NTT Advanced Technology Corporation and Innox Co Ltd (Japan), Nypro Inc (USA), and Youngchang Chemical Co Ltd (Korea). The consortium embraces total value chain involved in NIL, namely from tools (both for R&D and production), resist materials, templates (mould/stamp) to process know-how and applications. Currently, I.C.O.N. has defined two thematic application-oriented projects to be pursued namely Anti-reflection structures and Anti-bacterial structures.

Besides the launch of I.C.O.N., the Industrial Symposium concurrently held involved speakers from IMRE and overseas renowned NIL companies, namely NIL Technology ApS, Micro Resist Technology GmbH, NTT Advanced Technology (AT), and EVG Group. Topics of presentations covered the whole NIL value chain. IMRE presented their capability for the process know-how, NIL Technology and NTT AT showcased their capability in fabricating complex micro/nanostructured moulds/stamps for various applications, while Micro Resist Technology introduced their proprietary resist materials for both thermal and UV-NIL for the industrial use and EVG Group displayed their NIL equipments, especially highlighted their state-of-the-art Step and Repeat NIL System.

To emphasize the NIL capability of IMRE, we'd like to highlight the two presentations given by the IMRE's researchers. First is the capability of IMRE to directly imprint the ultra-fine nanostructures of desired oxide materials by the use of organometallic chemicals along with a cross-linker and initiator for free radical polymerization of the mixture, followed by heat treatment process as soon as the imprinting process is done. It lies in IMRE's capability to synthesize the right resist mixture of chemicals mentioned above and formulate the right heat treatment parameters recipe for obtaining the desired final dimension of the pattern. Currently, the group has demonstrated large-area (>1 cm x 1 cm) direct fabrication of ~20 nm features of TiO2 using NIL from a titanium methacrylate and EDMA mixture. Polymerization strengthens the imprinted structures, thereby giving ~100% yield after demolding. Heat-treatment of the imprinted structures at 400 °C resulted in the loss of organics and their subsequent shrinkage (~75%) without the loss of integrity or aspect ratio, and converted them to TiO2 nanostructures as small as ~20 nm wide. Furthermore, they extended this method to directly imprinted SiO2 molds, which can be used as a daughter mold beating mother mold with higher resolution or etch mask for patterning high areal density bit patterned media and PZT (piezoelectric material).

Secondly is IMRE's creativity in utilizing NIL to fabricate anodic porous alumina (AAO) template. Simple and inexpensive AAO is interesting for many applications such as for microfiltration, CNT growth template, and decorative & protective films. Nevertheless, it is difficult to fabricate a highly ordered array of AAO over large area (currently limited to several microns) and directly integrate AAO on the substrates using the conventional methods of AAO fabrication. By using step and repeat NIL technology, highly ordered AAO can be more easily fabricated at large area (e.g. 4' wafer size) and without substrate breakage. High aspect ratio (1:10) can also be easily achieved, and inter-pore distance and pore-lattice configuration can be easily controlled.

The event was closed with a laboratory tour in IMRE that comprises the characterization laboratory and clean room fabrication facilities, including the nanoimprinters. IMRE owns two nanoimprinters: one capable of doing thermal and UV NIL at 4' wafer size, another capable of doing only UV NIL with step and repeat method at choices of 2, 4 and 8' wafer sizes. The latter is able to provide high resolution (down to 100 nm), sub-micron alignment, and 3-dimensional replications.

|

| Official signing of I.C.O.N. project agreement with all member representatives |

|

| Welcome address by the new Executive Director of IMRE, Professor Andy Hor |

|

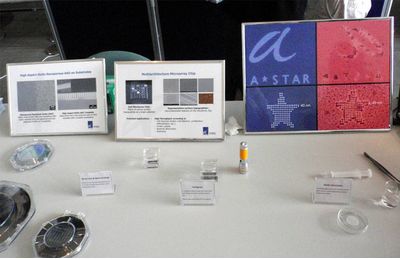

| Exhibition of products, produced by the NIL group in IMRE, including gecko structures, hologram surface, 20nm line & space gratings, and high aspect ratio AAO |

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||