Home > Nanotechnology Columns > Bo Varga > Nano Solar News: 2006 & January

|

Bo Varga Managing Director Silicon Valley Nano Ventures |

Abstract:

The focus for this column is recent nano solar news as well as a review of current and projected capture efficiency of solar cells as well as current and projected manufactured cost & wholesale prices of solar modules.

February 13th, 2007

Nano Solar News: 2006 & January

Nanotechnology & Solar Power News: 2006 & January 2007

This column will be published monthly, usually in the first week or two of the following month to allow time to evaluate new information. My focus is on nano & clean technology conferences, commercialization of nano technology in solar applications, companies, fundings, solar power issues, and other areas of interest to solar power. The focus for this column is recent nano solar news as well as a review of current and projected capture efficiency of solar cells. All quotations and sources are referenced and all opinions are the opinions of the columnist & not of Nanotechnology-Now.

The January http://www.ibfconferences.com 6th annual Nanotechnology Investing Forum attendance in Palm Springs did not increase from 2006, however the following IBF Clean Tech Investor Summit attendance in Palm Springs grew from 225 last year to ~500 this year, with a very strong focus on solar photo-voltaic technology.

Per Peter Grubstein, Founder & Managing Member of VC firm NGEN Partners said during his presentation "Two years ago 80% of our investments were nanotechnology companies. Today 80% of our investments are clean technology companies. And they are the same companies!"

Nanotechnology has clearly shifted from the R&D phase into the focus-on- commercialization phase, where the market and application & "whole product" are the major focus, rather than the enabling nano technology.

And this brings manufacturing into the foreground, where capital expenditures, cost of goods, cost of production, and yield become ever more important.

The strong commitment to Clean Technology by http://www.nsti.org at the upcoming Nanotechnology 2007 Conference this May - the world's largest & most comprehensive nano technology conference - is one example of this trend. This conference in Silicon Valley is strongly recommended -the focus of this conference & exhibition increases year to year from technology to markets, applications, products - and investors!

The upcoming Clean Tech Forum, February 19-22 in SF, one of the annual conferences staged by the Clean Tech Venture Network, is another venue where nanotechnology (broadly defined as the ability to measure & manipulate matter at the nano scale) is driving clean technology applications, especially renewable energy companies, including solar PV and solar thermal,

http://www.cleantech.com/index.cfm?pageSRC=SanFranciscoForum. At this time this Forum is only open to members, presenting companies, and qualified investors - unlike the IBF conferences that are open to anyone who can pay the entry fee.

The fundamental driver for solar PV & solar thermal is the efficiency & cost of conversion of sunlight to electricity or to heat. In either case, nano scale control of the materials used plus the ability to manufacture materials & devices at a large scale, on a high yield basis, with ever lower costs, and with a long field life, are basic to harvesting enough solar energy to compete with fossil fuels.

While almost all current photovoltaic modules manufactured today (90%+) are made from c-Si at 200+ micron thickness, the major thin film photovoltaic technology, a-Si relies on materials & process control at the nano scale. And companies such as First Solar that have successful launched CdTe based thin film photovoltaic modules or in the case of Boeing/Spectrolab based on GaAs.

Spectrolab uses a multiple junction technology - in this case up to 30 layers consisting of germanium layers to harvest infrared photons and layers of gallium arsenide to harvest different wavelengths of visible light. When coupled with a solar concentrator these cells delivers the equivalent of 240 suns, the cells operate at an efficiency of 40.7% versus the 12% to 22% for standard silicon cells.

(Department of Energy Announcement, December 5, 2005, Spectrolab)

Meanwhile In Palm Springs, Kieren Drain, CEO of Nanogram in Silicon Valley http://www.nanogram.com, presented a breakthrough in manufacturing & using nano scale silicon for the current PV industry dominated by c-Si solar cells. Although companies such as SunPower have successfully reduced wafer thickness to 200 microns (saving on very expensive solar grade silicon), Kieren announced that 20 micron thick solar cells are now possible to manufacture using Nanogram's proprietary technology.

As solar grade silicon is 50% of the cost of a solar module and 25% of the cost of an installed solar system on your roof, a 90% reduction in silicon usage has the potential to reduce module costs by 45% over the next few years.

This is in line with a presentation made by Renewable Energy Corporation (REC) at the http://www.jeffries.com European Alternative Energy & Clean Technology Conference that took place on October 17th, 2006 in London, where REC targeted a 46% reduction in c-Si PV modules by 2010 - without factoring in Nanogram's technical breakthrough! Using $1 cost basis in 2005 and 54 cents target in 2010, REC projected costs as follows:

Silicon costs in 2005 of 15 cents reduced in 2010 to 11 cents.

Wafer costs in 2005 of 23 cents reduced in 2010 to 11cents.

Cell costs of 26 cents in 2005 reduced in 2010 to 13 cents.

Module costs of 36 cents in 2005 reduced in 2010 to 24 cents.

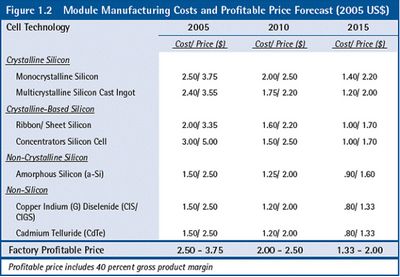

And if we look at the cost/price projections for 2010 and 2015 from http://www.prometheus.org/ we can see that the projected time to achieve this cost reduction was 2015. The cost/price data & assumptions are Peak Watt.

This is an industry consensus which does not take into account the impact of nano scale technology upon materials, devices, and manufacturing processes.

Or of the ability of a fully integrated producer like REC to drive inefficiencies out of the value chain & gain the benefits of ramping production volume.

|

To continue this thread, at the IEEE San Francisco Bay Area Nanotechnology Council meeting on January 16th Dr. Homer Antoniadis, CTO of http://www.innovalight.com, announced that Innovalight's silicon nanocrystalline ink holds the promise to bring flexible solar panels to less than $0.40 per watt.

Technical issues include manufacturing silicon & other nano particles reliably & at the required cost & scale. Scaling up to wide, large length rolls in roll to roll manufacturing is not a trivial issue and requires time to get a manufacturing process both to work and to get yield to economic levels. While Dr. Antoniadis did not give a timeline, I felt that he expected (and certainly his VC backers expect) to have large-scale manufacturing & product to market before 2015.

Other start-up companies that plan to use nano particles include two in Silicon Valley, Stion & Solexant. Stion has the backing of both Vinod Khosla, the well-known Tier 1 Silicon Valley venture capitalist as well as Moser Baer, a major CD manufacturer in India

Moser Baer Photo Voltaic of India is apparently taking a 20%-ish stake in Stion Corp (formerly NStructures), a Silicon Valley-based nanotech startup focusing on solar photovoltaics. Khosla Ventures and Braemar Energy Ventures participated in NStructures' Series A financing. This is the third equity investment by Moser Baer Photo Voltaic, after taking equity positions in solar concentrator technology firms Solaria and SolFocus. (source, http://www.insidegreentech.com - November 16, 2006)

Solexant is developing high efficiency low cost nanostructured solar cells. Solexant solar cells achieve high efficiency by incorporating nanomaterials that harvest light from the entire solar spectrum and achieve low cost by adopting roll to roll manufacturing process. (source, http://www.nsti.org/press - Presenter Profiles, May 4, 2006.)

And the original start-up (2001) targeting solar PV by using nanostructured tripods, Nanosys, http://www.nanosysinc.com/app/index.html, is apparently still moving forward with work in this area: "One potential product is a new type of solar cell that performs like a traditional solar cell, but can be configured like a light weight, flexible plastic. In particular, this technology has the potential to provide low cost solar power through currently available, high volume and inexpensive manufacturing techniques based on conventional film based processes such as roll to roll manufacturing. To develop our nanotechnology-enabled solar cells we are collaborating with several United States government agencies."

On another note Sharp announced a major breakthrough in a-Si technology on January 25th (source, http://www.physorg.com/news ) Sharp Corporation has successfully developed mass-production technology for stacked triple-junction thin-film solar cells by turning a conventional two-active-layer structure (amorphous silicon plus microcrystalline silicon) into a triple-junction structure with amorphous silicon (two active layers) and microcrystalline silicon (single active layer). This new architecture boosts cell conversion efficiency from 11% to 13% and module conversion efficiency from 8.6% to 10%. Mass production is slated to begin in May 2007 at Sharp's Katsuragi Plant in Nara Prefecture.

To put this announcement into perspective, please review the NREL September 2006 review of SPEC-SHEET RATINGS, From Manufacturers' Websites (Claims not verified) below. These efficiencies may be considered best cases. Particularly interesting is the Temperature Coefficient - the standard module efficiency ratings are measured at 25 degrees C or 72 degrees F. The Tcoeff gives you the loss in efficiency for each rise in degree C. That is, solar cells and modules have an optimal operating temperature and as the temperature rises, for example to 50 degrees C or 122 degrees F - the top rated Sunpower module declines in efficiency by 25 x 0.38% = 9.5%, reducing actual operating efficiency from 17.7% to 8.2% at this temperature.

|

Clearly there is a lot of room for improvement in solar cell & module technology, including various approaches to cooling solar cells at high temperatures, better materials, better device designs, better manufacturing processes & so on. At the SEMI nanoforum staged October 31 to November 2, 2006 in San Jose, senior technical speakers from both Konarka http://www.konarka.com and Nanosolar http://www.nanosolar.com stressed the importance of manufacturing efficiencies, including CAPEX, throughput, & yield. Both speakers expressed serious doubts about the long term viability of the current c-Si paradigm by pointing out that while the semiconductor industry relies upon 100x - 1,000x markup on the price on their raw material, the c-Si solar PV industry raw material cost is on the order of 20% - 25% today, allowing a markup at module selling prices on the order of 4x to 5x.

Both speakers presented the case that only roll to roll manufacturing, similar to the process used in printing newspapers, can deliver the manufacturing efficiencies required to dominate the solar PV market in the long run. This topic will be covered in another column.

Finally it is interesting to see in the February, 2007 edition of Scientific American, page 11, that Angela Belcher's group at MIT http://belcher10.mit.edu/index.htm is working on solar cells, having already developed leading edge technology for self assembly of flat panel display and battery elements by using viruses & phages to create controlled nanostructures. "Solar cells are a major focus in our work at MIT right now. We are trying to take advantage of biology to template different materials in a very small space and in close proximity to act as full spectrum solar absorbers."

Please send your feedback, ideas, and suggestions to Bo Varga via

Bo has 28 years experience developing business strategy, funding, & strategic alliances for start-up and early stage companies in Silicon Valley & globally.

He has six years experience with the commercialization of nano technology & clean technology ventures & a very strong interest in helping clean energy & clean technology water projects.

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||