Home > Press > A new approach to making airplane parts, minus the massive infrastructure: Carbon nanotube film produces aerospace-grade composites with no need for huge ovens or autoclaves.

|

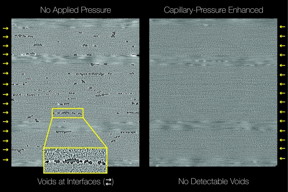

| MIT researchers have devised a way to manufacture autoclave-formulated aerospace-grade advanced carbon fiber composites without utilizing applied pressure from an autoclave. Cross-sections of the composites show that a nanoporous film with morphology-controlled nanoscale capillaries provides the needed pressure at the interfaces in layered polymeric architectures. Image: courtesy of the researchers |

Abstract:

A modern airplane’s fuselage is made from multiple sheets of different composite materials, like so many layers in a phyllo-dough pastry. Once these layers are stacked and molded into the shape of a fuselage, the structures are wheeled into warehouse-sized ovens and autoclaves, where the layers fuse together to form a resilient, aerodynamic shell.

A new approach to making airplane parts, minus the massive infrastructure: Carbon nanotube film produces aerospace-grade composites with no need for huge ovens or autoclaves.

Cambridge, MA | Posted on January 13th, 2020Now MIT engineers have developed a method to produce aerospace-grade composites without the enormous ovens and pressure vessels. The technique may help to speed up the manufacturing of airplanes and other large, high-performance composite structures, such as blades for wind turbines.

The researchers detail their new method in a paper published today in the journal Advanced Materials Interfaces.

“If you’re making a primary structure like a fuselage or wing, you need to build a pressure vessel, or autoclave, the size of a two- or three-story building, which itself requires time and money to pressurize,” says Brian Wardle, professor of aeronautics and astronautics at MIT. “These things are massive pieces of infrastructure. Now we can make primary structure materials without autoclave pressure, so we can get rid of all that infrastructure.”

Wardle’s co-authors on the paper are lead author and MIT postdoc Jeonyoon Lee, and Seth Kessler of Metis Design Corporation, an aerospace structural health monitoring company based in Boston.

Out of the oven, into a blanket

In 2015, Lee led the team, along with another member of Wardle’s lab, in creating a method to make aerospace-grade composites without requiring an oven to fuse the materials together. Instead of placing layers of material inside an oven to cure, the researchers essentially wrapped them in an ultrathin film of carbon nanotubes (CNTs). When they applied an electric current to the film, the CNTs, like a nanoscale electric blanket, quickly generated heat, causing the materials within to cure and fuse together.

With this out-of-oven, or OoO, technique, the team was able to produce composites as strong as the materials made in conventional airplane manufacturing ovens, using only 1 percent of the energy.

The researchers next looked for ways to make high-performance composites without the use of large, high-pressure autoclaves — building-sized vessels that generate high enough pressures to press materials together, squeezing out any voids, or air pockets, at their interface.

“There’s microscopic surface roughness on each ply of a material, and when you put two plys together, air gets trapped between the rough areas, which is the primary source of voids and weakness in a composite,” Wardle says. “An autoclave can push those voids to the edges and get rid of them.”

Researchers including Wardle’s group have explored “out-of-autoclave,” or OoA, techniques to manufacture composites without using the huge machines. But most of these techniques have produced composites where nearly 1 percent of the material contains voids, which can compromise a material’s strength and lifetime. In comparison, aerospace-grade composites made in autoclaves are of such high quality that any voids they contain are neglible and not easily measured.

“The problem with these OoA approaches is also that the materials have been specially formulated, and none are qualified for primary structures such as wings and fuselages,” Wardle says. “They’re making some inroads in secondary structures, such as flaps and doors, but they still get voids.”

Straw pressure

Part of Wardle’s work focuses on developing nanoporous networks — ultrathin films made from aligned, microscopic material such as carbon nanotubes, that can be engineered with exceptional properties, including color, strength, and electrical capacity. The researchers wondered whether these nanoporous films could be used in place of giant autoclaves to squeeze out voids between two material layers, as unlikely as that may seem.

A thin film of carbon nanotubes is somewhat like a dense forest of trees, and the spaces between the trees can function like thin nanoscale tubes, or capillaries. A capillary such as a straw can generate pressure based on its geometry and its surface energy, or the material’s ability to attract liquids or other materials.

The researchers proposed that if a thin film of carbon nanotubes were sandwiched between two materials, then, as the materials were heated and softened, the capillaries between the carbon nanotubes should have a surface energy and geometry such that they would draw the materials in toward each other, rather than leaving a void between them. Lee calculated that the capillary pressure should be larger than the pressure applied by the autoclaves.

The researchers tested their idea in the lab by growing films of vertically aligned carbon nanotubes using a technique they previously developed, then laying the films between layers of materials that are typically used in the autoclave-based manufacturing of primary aircraft structures. They wrapped the layers in a second film of carbon nanotubes, which they applied an electric current to to heat it up. They observed that as the materials heated and softened in response, they were pulled into the capillaries of the intermediate CNT film.

The resulting composite lacked voids, similar to aerospace-grade composites that are produced in an autoclave. The researchers subjected the composites to strength tests, attempting to push the layers apart, the idea being that voids, if present, would allow the layers to separate more easily.

“In these tests, we found that our out-of-autoclave composite was just as strong as the gold-standard autoclave process composite used for primary aerospace structures,” Wardle says.

The team will next look for ways to scale up the pressure-generating CNT film. In their experiments, they worked with samples measuring several centimeters wide — large enough to demonstrate that nanoporous networks can pressurize materials and prevent voids from forming. To make this process viable for manufacturing entire wings and fuselages, researchers will have to find ways to manufacture CNT and other nanoporous films at a much larger scale.

“There are ways to make really large blankets of this stuff, and there’s continuous production of sheets, yarns, and rolls of material that can be incorporated in the process,” Wardle says.

He plans also to explore different formulations of nanoporous films, engineering capillaries of varying surface energies and geometries, to be able to pressurize and bond other high-performance materials.

“Now we have this new material solution that can provide on-demand pressure where you need it,” Wardle says. “Beyond airplanes, most of the composite production in the world is composite pipes, for water, gas, oil, all the things that go in and out of our lives. This could make making all those things, without the oven and autoclave infrastructure.”

This research was supported, in part, by Airbus, ANSYS, Embraer, Lockheed Martin, Saab AB, Saertex, and Teijin Carbon America through MIT’s Nano-Engineered Composite aerospace Structures (NECST) Consortium.

####

For more information, please click here

Contacts:

Abby Abazorius, MIT News Office

617.53.2709

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() PAPER: “Void-free layered polymeric architectures via capillary-action of nanoporous films.”:

PAPER: “Void-free layered polymeric architectures via capillary-action of nanoporous films.”:

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||