Home > Press > A new way to make microstructured surfaces: Method can produce strong, lightweight materials with specific surface properties

|

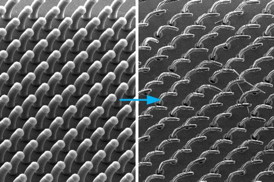

| New process developed by MIT’s John Hart and others can produce arrays of 3-D shapes, based on carbon nanotubes growing from a surface. In this example, all the nanotubes are aligned to curve in the same direction.

Illustration courtesy of the researchers |

Abstract:

A team of researchers has created a new way of manufacturing microstructured surfaces that have novel three-dimensional textures. These surfaces, made by self-assembly of carbon nanotubes, could exhibit a variety of useful properties — including controllable mechanical stiffness and strength, or the ability to repel water in a certain direction.

A new way to make microstructured surfaces: Method can produce strong, lightweight materials with specific surface properties

Cambridge, MA | Posted on July 29th, 2014"We have demonstrated that mechanical forces can be used to direct nanostructures to form complex three-dimensional microstructures, and that we can independently control … the mechanical properties of the microstructures," says A. John Hart, the Mitsui Career Development Associate Professor of Mechanical Engineering at MIT and senior author of a paper describing the new technique in the journal Nature Communications.

The technique works by inducing carbon nanotubes to bend as they grow. The mechanism is analogous to the bending of a bimetallic strip, used as the control in old thermostats, as it warms: One material expands faster than another bonded to it. But in this new process, the material bends as it is produced by a chemical reaction.

The process begins by printing two patterns onto a substrate: One is a catalyst of carbon nanotubes; the second material modifies the growth rate of the nanotubes. By offsetting the two patterns, the researchers showed that the nanotubes bend into predictable shapes as they extend.

"We can specify these simple two-dimensional instructions, and cause the nanotubes to form complex shapes in three dimensions," says Hart. Where nanotubes growing at different rates are adjacent, "they push and pull on each other," producing more complex forms, Hart explains. "It's a new principle of using mechanics to control the growth of a nanostructured material," he says.

Few high-throughput manufacturing processes can achieve such flexibility in creating three-dimensional structures, Hart says. This technique, he adds, is attractive because it can be used to create large expanses of the structures simultaneously; the shape of each structure can be specified by designing the starting pattern. Hart says the technique could also enable control of other properties, such as electrical and thermal conductivity and chemical reactivity, by attaching various coatings to the carbon nanotubes after they grow.

"If you coat the structures after the growth process, you can exquisitely modify their properties," says Hart. For example, coating the nanotubes with ceramic, using a method called atomic layer deposition, allows the mechanical properties of the structures to be controlled. "When a thick coating is deposited, we have a surface with exceptional stiffness, strength, and toughness relative to [its] density," Hart explains. "When a thin coating is deposited, the structures are very flexible and resilient."

This approach may also enable "high-fidelity replication of the intricate structures found on the skins of certain plants and animals," Hart says, and could make it possible to mass-produce surfaces with specialized characteristics, such as the water-repellent and adhesive ability of some insects. "We're interested in controlling these fundamental properties using scalable manufacturing techniques," Hart says.

Hart says the surfaces have the durability of carbon nanotubes, which could allow them to survive in harsh environments, and could be connected to electronics and function as sensors of mechanical or chemical signals.

Along with Hart, the research team included Michael de Volder of Cambridge University; Sei Jin Park, a visiting doctoral student from the University of Michigan; and Sameh Tawfick, a former postdoc at MIT who is now at the University of Illinois at Urbana-Champaign. The work was supported by the European Research Council, the Defense Advanced Research Projects Agency, and the Air Force Office of Scientific Research.

Written by David L. Chandler, MIT News Office

####

For more information, please click here

Contacts:

Abby Abazorius

MIT News Office

617.253.2709

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Faculty Highlight: A. John Hart

Faculty Highlight: A. John Hart

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Water

![]() Taking salt out of the water equation October 7th, 2022

Taking salt out of the water equation October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||