Home > Press > Researchers Grow Carbon Nanofibers Using Ambient Air, Without Toxic Ammonia

|

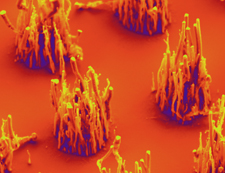

| Researchers have shown they can grow vertically-aligned carbon nanofibers using ambient air, rather than ammonia gas. Click to enlarge image. Credit: Anatoli Melechko. |

Abstract:

"Aerosynthesis: Growth of Vertically-aligned Carbon Nanofibres with Air DC Plasma"

Authors: A. Kodumagulla, V. Varanasi, R.C. Pearce, W.C. Wu, J.B. Tracy, and A.V. Melechko, North Carolina State University; D.K. Hensley and T.E. McKnight, Oak Ridge National Laboratory

Published: March 12, 2014, Nanomaterials and Nanotechnology

DOI: 10.5772/58449

Abstract: Vertically-aligned carbon nanofibres (VACNFs) have been synthesized in a mixture of acetone and air using catalytic DC plasma-enhanced chemical vapour deposition. Typically, ammonia or hydrogen is used as an etchant gas in the mixture to remove carbon that otherwise passivates the catalyst surface and impedes growth. Our demonstration of the use of air as the etchant gas opens up the possibility that ion etching could be sufficient to maintain the catalytic activity state during synthesis. It also demonstrates a path toward growing VACNFs in the open atmosphere.

Researchers Grow Carbon Nanofibers Using Ambient Air, Without Toxic Ammonia

Raleigh, NC | Posted on March 24th, 2014Researchers from North Carolina State University have demonstrated that vertically aligned carbon nanofibers (VACNFs) can be manufactured using ambient air, making the manufacturing process safer and less expensive. VACNFs hold promise for use in gene-delivery tools, sensors, batteries and other technologies.

Conventional techniques for creating VACNFs rely on the use of ammonia gas, which is toxic. And while ammonia gas is not expensive, it's not free.

"This discovery makes VACNF manufacture safer and cheaper, because you don't need to account for the risks and costs associated with ammonia gas," says Dr. Anatoli Melechko, an adjunct associate professor of materials science and engineering at NC State and senior author of a paper on the work. "This also raises the possibility of growing VACNFs on a much larger scale."

In the most common method for VACNF manufacture, a substrate coated with nickel nanoparticles is placed in a vacuum chamber and heated to 700 degrees Celsius. The chamber is then filled with ammonia gas and either acetylene or acetone gas, which contain carbon. When a voltage is applied to the substrate and a corresponding anode in the chamber, the gas is ionized. This creates plasma that directs the nanofiber growth. The nickel nanoparticles free carbon atoms, which begin forming VACNFs beneath the nickel catalyst nanoparticles. However, if too much carbon forms on the nanoparticles it can pile up and clog the passage of carbon atoms to the growing nanofibers.

Ammonia's role in this process is to keep carbon from forming a crust on the nanoparticles, which would prevent the formation of VACNFs.

"We didn't think we could grow VACNFs without ammonia or a hydrogen gas," Melechko says. But he tried anyway.

Melechko's team tried the conventional vacuum technique, using acetone gas. However, they replaced the ammonia gas with ambient air - and it worked. The size, shape and alignment of the VACNFs were consistent with the VACNFs produced using conventional techniques.

"We did this using the vacuum technique without ammonia," Melechko says. "But it creates the theoretical possibility of growing VACNFs without a vacuum chamber. If that can be done, you would be able to create VACNFs on a much larger scale."

Melechko also highlights the role of two high school students involved in the work: A. Kodumagulla and V. Varanasi, who are lead authors of the paper. "This discovery would not have happened if not for their approach to the problem, which was free from any preconceptions," Melechko says. "I think they're future materials engineers."

####

For more information, please click here

Contacts:

Matt Shipman

919-515-6386

Copyright © North Carolina State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Chemistry

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Sensors

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||