Home > Press > Shining a light on tiny polymer shapes: Visiting graduate student studies high-throughput manufacturing of precisely shaped microparticles

|

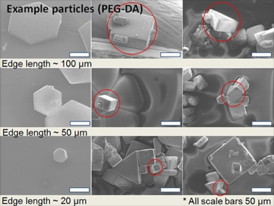

| Shown here are examples of micro shapes polymerized by ultraviolet light in polyethylene glycol diacrylate (PEG-DA). Image courtesy of Ryan Oliver/Mechanosynthesis Group |

Abstract:

Ryan Oliver, a visiting graduate student in the lab of associate professor of mechanical engineering A. John Hart, is developing a technique called maskless fluidic lithography that creates unique shapes in a liquid polymer by exposing it to patterned ultraviolet light, a process known as photopolymerization.

Shining a light on tiny polymer shapes: Visiting graduate student studies high-throughput manufacturing of precisely shaped microparticles

Cambridge, MA | Posted on February 11th, 2014For example, Oliver uses a projector to pattern shapes in polyethylene glycol diacrylate (PEG-DA), a common biocompatible polymer. Unlike semiconductor processing, which uses wafer masks produced as single-use items, the integrated projection system allows for rapid change of the pattern.

Key to the system is a Texas Instruments digital micromirror device (DMD) that can turn micromirrors on and off 32,552 times a second. "Because the mirrors are so fast, we can make decisions very quickly, which is hard to do with a masked system," Oliver says. "You would spend several days ordering or fabricating a mask rather than milliseconds if you needed a new pattern." By controlling how long each mirror is switched on during a single second, the system varies the intensity of the projection to form two-dimensional or three-dimensional structures. Oliver likens the process to layer-by-layer assembly in a single step.

Ryan and Hart chose the stop-flow lithography approach, inspired by research from Professor Patrick Doyle's group at MIT, while they were at the University of Michigan as a platform for studying the manufacture of large quantities of custom microparticles. Their vision is to use particles that are designed to work together and act as a sensitive biosensor. To realize the vision, Ryan has a goal to produce microparticles from about 250 nanometers to about 100 microns in a library of shapes such as diamonds, triangles, squares, and octagons. "We're exploring methods of taking them down to the nanoscale, but the current system produces microparticles," Oliver says. "What sets this method apart is, one, high throughput; two, flexibility using the DMD chip; and three, the fact that you can control the shape as well as the size of the particles, and possibly the chemistry."

Oliver is studying how to manipulate a collection of polymer particles on a liquid surface in order to assemble them in specific ways. "We needed a platform in order to synthesize microparticles that we could perform self-assembly experiments on, because that promises to allow us to build sensors that we can't build now, that are too complex — they're made out of too many types of materials to fabricate using traditional manufacturing methods," Oliver says. "A lot of applications may require control over the shape, the surface finish, the chemistry, and the size of microparticles, so we've been exploring this as a method toward that end, as well as understanding how to improve the shape accuracy while increasing throughput."

Such templated polymers can be used for a range of processes, from drug delivery to cell culture assays to casting molds. Researchers in Hart's Mechanosynthesis Lab also adapted the ultraviolet-light-based polymerization to a roll-to-roll system in addition to the microfluidic system.

One drawback with PEG, which is a hydrogel, is that it readily absorbs water, so it can swell or change shape in wet environments.

"Beyond the manufacturing process, we are interested in secondary means to assemble the particles into complex, hierarchical structures, such as those including cells," Oliver says. "These assemblies could be very useful for performing high-throughput bioassays or building novel tissue-like structures."

Oliver followed Hart to MIT from the University of Michigan. He led work on the Robofurnace project, an automated bench-top chemical vapor deposition system for growing carbon nanotubes and other nanomaterials. He hopes to finish his PhD through Michigan in August. His dissertation will focus on a suite of tools for high-throughput polymer micromanufacturing and manipulation, including the direct-write fluidic lithography method. Oliver presented his work on polymers at a Materials Research Society meeting and at the Enabling Nanofabrication for Rapid Innovation workshop in 2013.

Denis Paiste

Materials Processing Center

####

For more information, please click here

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Microfluidics/Nanofluidics

![]() Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

Implantable device shrinks pancreatic tumors: Taming pancreatic cancer with intratumoral immunotherapy April 14th, 2023

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

![]() Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Oregon State University research pushes closer to new therapy for pancreatic cancer May 6th, 2022

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Self Assembly

![]() Liquid crystal templated chiral nanomaterials October 14th, 2022

Liquid crystal templated chiral nanomaterials October 14th, 2022

![]() Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

![]() Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

![]() Nanostructures get complex with electron equivalents: Nanoparticles of two different sizes break away from symmetrical designs January 14th, 2022

Nanostructures get complex with electron equivalents: Nanoparticles of two different sizes break away from symmetrical designs January 14th, 2022

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||