Home > Press > Stanford engineers show how to optimize carbon nanotube arrays for use in hot spots

|

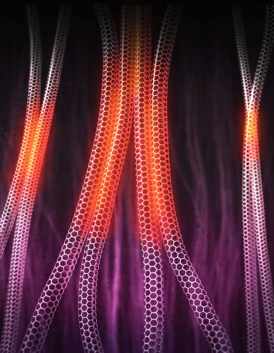

| A stylized rendition of single walled carbon nanotubes that are just one atom thick in diameter. The red zones show where the attraction caused by van der Waals forces has bent or "zipped" two adjacent CNTs together. |

Abstract:

Experimental evidence and computer simulations suggest how to grow structures with the best trade offs between three desired characteristics: strength, flexibility and the ability to dissipate heat.

Stanford engineers show how to optimize carbon nanotube arrays for use in hot spots

Stanford, CA | Posted on December 2nd, 2013When engineers design devices, they must often join together two materials that expand and contract at different rates as temperatures change. Such thermal differences can cause problems if, for instance, a semiconductor chip is plugged into a socket that can't expand and contract rapidly enough to maintain an unbroken contact over time.

The potential for failure at such critical junctures has intensified as devices have shrunk to the nano scale, bringing subtle forces into play that tug at atoms and molecules, causing strains that are difficult to observe, much less avoid.

Writing in the Proceedings of the National Academy (PNAS), Stanford engineers report on how to create carbon nanotube structures that remain strong and supple at these critical interfaces where thermal stress is intrinsic to the design.

"Think about the heat sink for a microprocessor, " said senior PNAS author Kenneth Goodson, Professor and Bosch Chair of Mechanical Engineering at Stanford. "It is exposed to high heat fluxes for long periods of time, and repeated instances of heating and cooling."

At present materials like solder and gels are used at such junctions. But as electronics continue to shrink, more electrical power gets pushed through smaller circuits, putting materials under ever increasing thermal stress.

"Solder has a high thermal conductivity, but it's stiff," Goodson said, explaining why his lab continues to experiment with vertically-aligned carbon nanotubes. Just before this PNAS contribution, his team described the favorable thermal properties of nanotubes in an article for Reviews of Modern Physics (Vol. 85, pp. 1296-1327).

Nanotubes are infinitesimally thin strands of carbon atoms that have the potential to be efficient at conducting heat. They are also strong for their size, and can be flexible depending on how they are fabricated.

The Stanford PNAS paper was based on experiments and simulations designed to reveal how to create carbon nanotube (CNT) structures with the optimal blend of all three characteristics - strength, flexibility, and heat conductivity - that are required in critical junctures where thermal stress is a fact of life.

The Stanford paper represents about five years of teamwork centered in the Stanford Mechanical Engineering Department including experiments led by first author Yoonjin Won, who was then a doctoral student in Mechanical Engineering.

She used a variety of existing techniques to assemble CNTs with different structural characteristics, and then measured the flexibility (also called modulus) and thermal conductivity of each structure to look for the optimal structure.

Left to nature, the carbon atoms that form CNTs will create structures that - if we could see them -- resemble a bowl of spaghetti.

But Won worked with collaborators at the University of Tokyo to create CNTs that grew up relatively straight, like grasses. Some degree of entanglement still occurred. Precise control of CNT growth remains beyond the reach of science.

Nevertheless, Won's experiments showed that longer CNTs, grown less densely together, seemed to have the best combination of flexibility and strength for use in electronics and other industrial applications where thermal stress is expected.

To some degree her findings represent a tradeoff. Shorter and denser CNT structures are stronger and more efficient at dissipating heat. But they are also more entangled and stiffer. Won's experimental results showed that as CNT strands grew longer, they tended to grow straighter and were less tangled. This increased the flexibility of the structure, albeit with some acceptable losses in the other two parameters.

Because the ultimate goal of this work is to reveal how to optimize CNT structures for use as thermal transfer materials, the Stanford team built a computer simulation of the CNT assembly process with an eye toward understanding how the CNTs became bent and entangled despite efforts to grow them straight.

Work on the simulation was led by Wei Cai, an Associate Professor of Mechanical Engineering at Stanford, who holds a courtesy appointment in Materials Science and Engineering. The Stanford scientists wanted to understand the manner in which van der Waals forces influence the growth of CNTs.

These forces are named for the Dutch physicist who first described the weak attractions that exist between molecules - attractions that could not be explained by other known forces such as the chemical bonds that result when atoms share electrons.

Cai said that whereas van der Waals forces may not be critical in other types of structures, carbon nanotubes are so thin -- a nanometer thick in diameter -- that these minute forces could fundamentally affect them.

That is in fact what the simulation showed. Imagine a CNT attempting to grow straight, only to be bent to one side by the van der Waal attraction of another CNT crossing near its top, and perhaps bent to the other side by a different CNT that nears its bottom.

Taken together, the experimental results and computer simulation reinforce the findings that longer, less entangled CNTs would offer the best mixture of the desired characteristics strength, flexibility and heat transfer. But due to the van der Waals forces operating on these atom-thick carbon tubes, engineers are going to have to accept some bending and irregularity as they strive to create workable, though less than ideal, structures for dissipating heat.

"When you hear about nanotechnology it's usually about the superlatives, the strongest this, the thinnest that," Goodson said. "But we think is the answers will lie in finding unique combinations of properties, in this case something that's strong and conducts heat like a metal, but can flex and bend as well."

Other contributors include Yuan Gao, Matthew Panzer and Professor Thomas Kenny, who did their work at Stanford University; Rong Xiang, with the School of Physics and Engineering at Sun Yat-sen University in China; and Shigeo Maruyama with the Department of Mechanical Engineering at the University of Tokyo.

The work was sponsored by the Office of Naval Research, the National Science Foundation, the Semiconductor Research Corporation and the Air Force Office of Scientific Research.

Tom Abate is the Associate Director of Communications at Stanford Engineering

####

For more information, please click here

Contacts:

Tom Abate

Stanford Engineering

650-736-2245

Copyright © Stanford School of Engineering

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||