Home > Press > Caltech Researchers Develop Nanoscale Structures with Superior Mechanical Properties

|

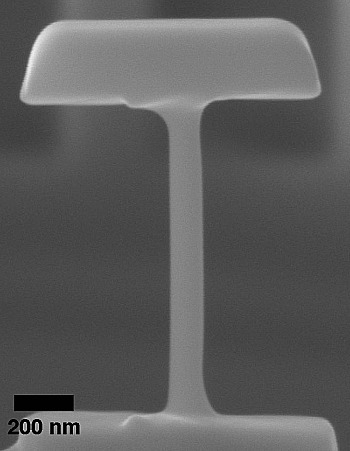

| Scanning electron micrograph of a typical as-fabricated 100-nm-diameter tensile sample. Credit: Dongchan Jang/Caltech |

Abstract:

Researchers at the California Institute of Technology (Caltech) have developed a way to make some notoriously brittle materials ductile—yet stronger than ever—simply by reducing their size.

Caltech Researchers Develop Nanoscale Structures with Superior Mechanical Properties

Pasadena, CA | Posted on February 10th, 2010The work, by Dongchan Jang, senior postdoctoral scholar, and Julia R. Greer, assistant professor of materials science and mechanics at Caltech, could eventually lead to the development of innovative, superstrong, yet light and damage-tolerant materials. These new materials could be used as components in structural applications, such as in lightweight aerospace vehicles that last longer under extreme environmental conditions and in naval vessels that are resistant to corrosion and wear.

A paper about the work appears in the February 7 advance online edition of the journal Nature Materials.

"Historically," says Greer, "structural materials have always had to rely on their processing conditions, and thereby have been 'slaves' to their properties." For example, ceramics are very strong, which makes them great for structural applications. At the same time, these materials are very heavy, which is problematic for many applications, and they are extremely brittle, which is less than ideal for supporting heavy loads. In fact, says Greer, "they fail catastrophically under mechanical loads." Metals and alloys, on the other hand, are ductile, and therefore unlikely to shatter, but they lack the strength of ceramics.

Materials scientists have developed an intriguing class of materials called glassy metallic alloys, which are amorphous and lack the crystalline structure of traditional metals. The materials, also known as metallic glasses, are composed of random arrangements of metallic elements like zirconium, titanium, copper, and nickel. They are lightweight—a "huge advantage" for their incorporation into new types of devices, Greer says—and yet are comparable in strength to ceramics. Unfortunately, their random structure makes metallic glasses quite brittle. "They also fail catastrophically under tensile loads," she says.

But now Greer and Jang, the first author on the Nature Materials paper, have developed a strategy to overcome these obstacles—by making metallic glasses that are almost vanishingly small.

The scientists devised a process to make zirconium-rich metallic glass pillars that are just 100 nanometers in diameter—roughly 400 times narrower than the width of a human hair. At this size, Greer says, "the metallic glasses become not only even stronger, but also ductile, which means they can be deformed to a certain elongation without breaking. Strength plus ductility," she says, represents "a very lucrative combination for structural applications."

As yet, there are no immediate applications for the new materials, although it may be possible to combine the nanopillars into arrays, which could then form the building blocks of larger hierarchical structures with the strength and ductility of the smaller objects.

The work, however, "convincingly shows that 'size' can be successfully used as a design parameter," Greer says. "We are entering a new era in materials science, where structural materials can be created not only by utilizing monolith structures, like ceramics and metals, but also by introducing 'architectural' features into them."

For example, Greer is working toward fabricating a "brick-and-mortar" architecture using tiny plates of a metallic glass and ultrafine-grained ductile metal with nanoscale dimensions that could then be used to fabricate new engineering composites with amplified strength and ductility.

To use this architecture-driven approach to create structural materials with enhanced properties—that are, for example, superstrong, yet light and ductile—researchers must understand how each constituent part deforms during use and under stress.

"Our findings," she says, "provide a powerful foundation for utilizing nanoscale components, which are capable of sustaining very high loads without exhibiting catastrophic failure, in bulk-scale structural applications specifically by incorporating architectural and microstructural control."

Adds Greer: "The particularly cool aspect of the experiment is that it is nearly impossible to do! Dongchan, my amazing postdoc, was able to make individual 100-nanometer-diameter tensile metallic glass nanopillar samples, which no one had ever done before, and then used our custom-built in situ mechanical deformation instrument, SEMentor, to perform the experiments. He fabricated the samples, tested them, and analyzed the data. Together we were able to interpret the results and to formulate the phenomenological theory, but the credit goes all to him."

The work in the Nature Materials paper, "Transition from a strong-yet-brittle to a stronger-and-ductile state by size reduction of metallic glasses," was funded by the National Science Foundation and the Office of Naval Research, and utilized the fabrication and characterization facilities of the Kavli Nanoscience Institute at Caltech.

####

About Caltech

The mission of the California Institute of Technology is to expand human knowledge and benefit society through research integrated with education. We investigate the most challenging, fundamental problems in science and technology in a singularly collegial, interdisciplinary atmosphere, while educating outstanding students to become creative members of society.

For more information, please click here

Contacts:

Kathy Svitil

Copyright © Caltech

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Marine/Watercraft

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

![]() Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes March 3rd, 2021

Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes March 3rd, 2021

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||