Home > Press > Researchers Find Better Way to Manufacture Fast Computer Chips

|

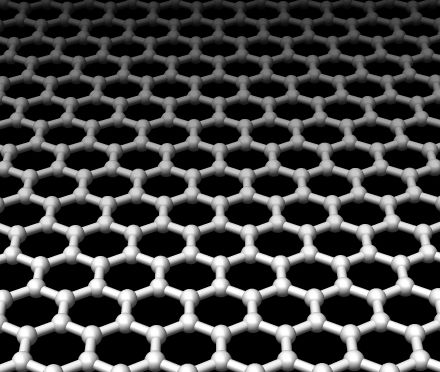

| Graphene is an atomic-scale honeycomb lattice made of carbon atoms. Source: Wikipedia. |

Abstract:

Engineers at Ohio State University are developing a technique for mass producing computer chips made from the same material found in pencils.

Researchers Find Better Way to Manufacture Fast Computer Chips

Columbus, OH | Posted on March 31st, 2009Experts believe that graphene -- the sheet-like form of carbon found in graphite pencils -- holds the key to smaller, faster electronics. It might also deliver quantum mechanical effects that could enable new kinds of electronics.

Until now, most researchers could only create tiny graphene devices one at a time, and only on traditional silicon oxide substrates. They couldn't control where they placed the devices on the substrate, and had to connect them to other electronics one at a time for testing.

In a paper published in the March 26 issue of the journal Advanced Materials, Nitin Padture and his colleagues describe a technique for stamping many graphene sheets onto a substrate at once, in precise locations.

"We designed the technique to mesh with standard chip-making practices," said Padture, College of Engineering Distinguished Professor in Materials Science and Engineering.

"Graphene has huge potential -- it's been dubbed ‘the new silicon,'" said Padture, who is also director of Ohio State's Center for Emergent Materials. "But there hasn't been a good process for high-throughput manufacturing it into chips. The industry has several decades of chip-making technology that we can tap into, if only we could create millions of these graphene structures in precise patterns on predetermined locations, repeatedly. This result is a proof-of-concept that we should be able to do just that."

Graphene is made of carbon atoms arranged in a hexagonal pattern resembling chicken wire. In graphite, many flat graphene sheets are stacked together.

"When you write with a pencil, you leave graphene sheets behind on the paper," Padture said. Each sheet is so thin -- a few tenths of a nanometer (billionths of a meter) -- that researchers think of it as a two-dimensional crystal.

Researchers have shown that a single sheet, or even a few sheets, of graphene can exhibit special properties. One such property is very high mobility, in which electrons can pass through it very quickly -- a good characteristic for fast electronics. Another is magnetism: magnetic fields could be used to control the spin of graphene electrons, which would enable spin-based electronics, also called spintronics.

Yet another characteristic is how dramatically graphene's properties change when it touches other materials. That makes it a good candidate material for chemical sensors.

In this method, Padture and his Ohio State colleagues carved graphite into different shapes -- a field of microscopic pillars, for example -- and then stamped the shapes onto silicon oxide surfaces.

"Think of a stack of graphene sheets in graphite as a deck of cards. When you bring it contact with the silicon oxide and pull it away, you can ‘split the deck' near the point of contact, leaving some layers of graphene behind. What we found through computer simulations was that the graphene surface interacts so strongly with the silicon oxide surface that the chemical bonds between the graphene layers weaken, and the lower layers split off," Padture said.

In this first series of experiments, the Ohio State researchers were able to stamp high-definition features that were ten layers thick, or thicker. The graphite stamp can then be used repeatedly on other predetermined locations on the same or other substrates, making this a mass-production method, potentially.

They used three different kinds of microscopes -- a scanning electron microscope, optical microscope, and atomic force microscope -- to measure the heights of the features, and assure that they were placed precisely on the substrate.

They eventually hope to stamp narrow features that are only one or two layers thick, by stamping on materials other than silicon oxide.

In computer simulations, they found that each material interacts differently with the graphene. So success might rely on finding just the right combination of substrate materials to coax the graphene to break off in one or two layers. This would also tailor the properties of the graphene.

Padture's co-authors on the paper include Dongsheng Li, a postdoctoral researcher, and Wolfgang Windl, associate professor of materials science and engineering.

This work was partially funded by the Center for Emergent Materials at Ohio State, which is a Materials Research Science & Engineering Center (MRSEC) sponsored by the National Science Foundation. The $17-million center is one of only 27 MRSECs (www.mrsec.org) around the country, and its main research focus is magnetoelectronics. Partial funding was also provided by Ohio State's Institute for Materials Research.

####

For more information, please click here

Contacts:

Nitin Padture

(614) 247-8114

Written by Pam Frost Gorder

(614) 292-9475

Copyright © Ohio State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Quantum Computing

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanoelectronics

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

![]() Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Atomic level deposition to extend Moore’s law and beyond July 15th, 2022

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||