Home > Press > Catalyst-free chemistry makes self-healing materials more practical

|

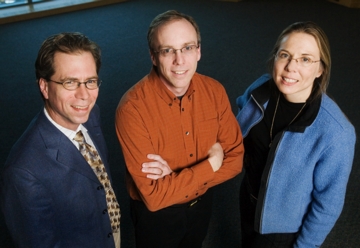

| A new catalyst-free, self-healing material system developed by Jeffrey Moore, the Murchison-Mallory Professor of Chemistry at Illinois, is flanked by Scott White, a professor of aerospace engineering, and Nancy Sottos, a professor of materials science and engineering, offers a far less expensive and far more practical way to repair composite materials used in structural applications ranging from airplane fuselages to wind-farm propeller blades. |

Abstract:

A new catalyst-free, self-healing material system developed by researchers at the University of Illinois offers a far less expensive and far more practical way to repair composite materials used in structural applications ranging from airplane fuselages to wind-farm propeller blades.

Catalyst-free chemistry makes self-healing materials more practical

CHAMPAIGN, IL | Posted on November 27th, 2007 The new self-healing system incorporates chlorobenzene microcapsules, as small as 150 microns in diameter, as an active solvent. The expensive, ruthenium-based Grubbs' catalyst, which was required in the researchers' first approach, is no longer needed.

"By removing the catalyst from our material system, we now have a simpler and more economical alternative for strength recovery after crack damage has occurred," said Jeffrey Moore, the Murchison-Mallory Professor of Chemistry at Illinois. "Self-healing of epoxy materials with encapsulated solvents can prevent further crack propagation, while recovering most of the material's mechanical integrity."

The new chemistry is described in a paper accepted for publication in Macromolecules, and posted on the journal's Web site.

During normal use, epoxy-based materials experience stresses that can cause cracking, which can lead to mechanical failure. Autonomous self-healing - a process in which the damage itself triggers the repair mechanism - can retain structural integrity and extend the lifetime of the material.

"Although we demonstrated the self-healing concept with a ruthenium-based catalyst, the cost of the catalyst made our original approach too expensive and impractical," said Moore, who also is affiliated with the university's Frederick Seitz Materials Research Laboratory and with the Beckman Institute. "Our new self-healing system is simple, very economical and potentially robust."

In the researchers' original approach, self-healing materials consisted of a microencapsulated healing agent (dicyclopentadiene) and Grubbs' catalyst embedded in an epoxy matrix. When the material cracked, microcapsules would rupture and release the healing agent, which then reacted with the catalyst to repair the damage.

In their new approach, when a crack forms in the epoxy material, microcapsules containing chlorobenzene break. The solvent disperses into the matrix, where it finds pockets of unreacted epoxy monomers. The solvent then carries the latent epoxy monomers into the crack, where polymerization takes place, restoring structural integrity.

In fracture tests, self-healing composites with catalyst-free chemistry recovered as much as 82 percent of their original fracture toughness.

The new catalyst-free chemistry has taken down the barriers to cost and level of difficulty, Moore said. "From an economics and simplicity standpoint, self-healing materials could become part of everyday life."

With Moore, co-authors of the paper are graduate student and lead author Mary Caruso, former postdoctoral research associate David Delafuente (now a chemistry and physics professor at Augusta State University), visiting University of Texas at Austin undergraduate student Victor Ho, materials science and engineering professor Nancy Sottos, and aerospace engineering professor Scott White.

The work was funded by the Air Force Office of Scientific Research and the National Science Foundation.

####

For more information, please click here

Contacts:

James E. Kloeppel

Physical Sciences Editor

217-244-1073

Jeffrey Moore

217-244-4024

Copyright © University of Illinois

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Aerospace/Space

![]() Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

Under pressure - space exploration in our time: Advancing space exploration through diverse collaborations and ethical policies February 16th, 2024

![]() Bridging light and electrons January 12th, 2024

Bridging light and electrons January 12th, 2024

![]() Manufacturing advances bring material back in vogue January 20th, 2023

Manufacturing advances bring material back in vogue January 20th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||