Home > Press > MTU engineers examine lithium battery defects

|

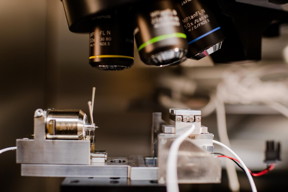

| Researchers at MTU and Oak Ridge National Lab observe nanoscale defects in lithium metal to better understand how lithium dendrites affect batteries. CREDIT Sarah Atkinson/Michigan Tech |

Abstract:

Historically, as in decades ago, rechargeable lithium metal batteries were dangerous. These batteries were quickly abandoned in favor of Li-ion batteries which contain no metallic lithium and are now widely used. In efforts to continue to drive energy density up and costs down, we are again exploring how to efficiently and safely use lithium metal in batteries. Solid state batteries, free of flammable liquids, may be the solution. However, progress has been slowed because lithium metal still finds a way to short circuit the battery and limit cycle life.

MTU engineers examine lithium battery defects

Houghton, MI | Posted on January 28th, 2020Solid-state lithium batteries are the Holy Grail of energy storage. With potential impacts on everything from personal mobile devices to industrial renewable energy, the difficulties are worth overcoming. The goal: Build a safe and long lived lithium battery. The challenge: Use a solid-state electrolyte and stop short circuiting from the formation and growth of lithium dendrites.

In a new invited feature paper published in the Journal of Materials Research, materials engineers from Michigan Technological University weigh in on the problem. Their take is an unusual one. They focus on the unique mechanics of lithium at dimensions that are a fraction of the diameter of the hair on your head -- much smaller scales than most others consider.

"People think of lithium as being soft as butter, so how can it possibly have the strength to penetrate through a ceramic solid electrolyte separator?" asked Erik Herbert, assistant professor of materials science and engineering at Michigan Tech and one of the study's leads. He says the answer is not intuitive -- smaller is stronger. Tiny physical defects like micro cracks, pores or surface roughness inevitably exist at the interface between a lithium anode and a solid electrolyte separator. Zooming in on the mechanics of lithium metal at length scales commensurate with those tiny interface defects, it turns out that lithium is much stronger than it is at macroscopic or bulk length scales.

"Lithium doesn't like stress any more than you or I like stress, so it's just trying to figure out how to make the pressure go away," Herbert said. "What we're saying is that at small length scales, where the lithium is not likely to have access to the normal mechanism it would use alleviate pressure, it has to rely on other, less efficient methods to relieve the stress."

In every crystalline metal like lithium, atomic level defects called dislocations are needed to relieve significant amounts of stress. At macroscopic or bulk length scales, dislocations get rid of stress efficiently because they allow adjacent planes of atoms to easily slide past one another like a deck of cards. However, at small length scales and high temperatures relative to the metal's melting point, the chance of finding dislocations within the stressed volume is very low. Under these conditions, the metal has to find another way to relieve the pressure. For lithium, that means switching to diffusion. The stress pushes lithium atoms away from the stressed volume - akin to being carried away on an atomic airport walkway. Compared to dislocation motion, diffusion is very inefficient. That means at small length scales, where diffusion controls stress relief rather than dislocation motion, lithium can support more than 100 times more stress or pressure than it can at macroscopic length scales.

Catastrophic problems may occur in what Herbert and his co-lead, MTU professor Stephen Hackney, call the defect danger zone. The zone is a window of physical defect dimensions defined by the stress relief competition between diffusion and dislocation motion. The worst-case scenario is a physical interface defect (a micro crack, pore or surface roughness) that is too big for efficient stress relief by diffusion but too small to enable stress relief by dislocation motion. In this reverse Goldilocks problem, high stresses within the lithium can cause the solid electrolyte and the whole battery to catastrophically fail. Interestingly, the danger zone size is the same size as the observed lithium dendrites.

"The very thin solid-state electrolytes and high current densities required to provide the battery power and short charging times expected by consumers are conditions that favor lithium dendrite failure, so the dendrite problem must be solved for the technology to progress," Hackney said. "But to make the solid-state technology viable, the power capability and cycle life limitations must be addressed. Of course, the first step in solving the problem is to understand the root cause, which is what we are trying to do with this current work."

Hackney points out that the smaller is stronger concept is not new. Materials engineers have studied length scale effect on mechanical behavior since the 1950s, though it has not been widely used in considering the lithium dendrite and solid electrolyte problem.

"We think this 'smaller is stronger' paradigm is directly applicable to the observed lithium dendrite size, and is confirmed by our experiments on very clean, thick Li films at strain rates relevant to the initiation of the dendrite instability during charging," Hackney said.

To rigorously examine their hypothesis, Herbert and Hackney perform nanoindentation experiments in high purity lithium films that are produced by a top battery researcher, Nancy Dudney of the Oak Ridge National Laboratory.

"The bulk properties of lithium metal are well characterized, but this may not be relevant at the scale of defects and inhomogeneous current distributions likely acting in very thin solid state batteries," Dudney said. "The model presented in this paper is the first to map conditions where the much stronger lithium will impact cyclelife performance. This will guide future investigation of solid electrolytes and battery designs."

Among the team's next steps, they plan to examine the effects of temperature and electrochemical cycling on the mechanical behavior of lithium at small length scales. This will help them better understand real-world conditions and strategies to make next-generation batteries immune to the formation and growth of lithium dendrites.

####

For more information, please click here

Contacts:

Allison Mills

@michigantech

Copyright © Michigan Technological University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Laboratories

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

![]() Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||