Home > Press > NEI Development Update on NANOMYTE® TC-5001, a Protective Coating for Zinc-Plated and Galvanized Steel

|

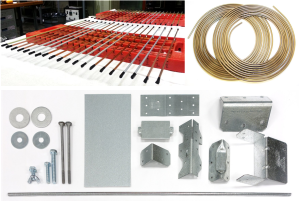

| Examples of structural parts that can be coated with TC-5001 (or related products) for corrosion protection are shown above. |

Abstract:

NEI Corporation has issued a product update, following the successful introduction of NANOMYTE® TC‐5001 - a nanotechnology-enabled, anti-corrosion coating for zinc‐plated and hot‐dip galvanized (HDG) steel. TC-5001 is a nanostructured composite coating consisting of organic and inorganic phases. It can be used either as a standalone coating or with the water-based, self-healing pretreatment, NANOMYTE® PT-100. In its current form, TC-5001 can be applied on metallic parts that have a zinc-based finish. Recent developments on its effectiveness and usage are outlined below.

NEI Development Update on NANOMYTE® TC-5001, a Protective Coating for Zinc-Plated and Galvanized Steel

Somerset, NJ | Posted on November 8th, 2014Field Trials

Over the past couple of years, TC-5001 and related products have found use in several applications in different industries. Examples include:

Automotive Components and Support Structures

Automotive parts coated in-house were subjected to salt-spray testing (ASTM B117) for over 1,000 hours to test the effects of corrosion; the TC-5001-coated parts showed no signs of white rust. Additionally, parts plated with alloys of zinc and aluminum were also coated with TC-5001 and are currently undergoing field testing.

Outdoor Structures

NANOMYTE® TC-5001-coated structures provide significant corrosion protection while supporting power lines in service. The coating has been successfully demonstrated to protect electrical grid components still in service for several months to date.

Hardware Components

Various TC-5001-coated nuts, bolts, and screws were exposed outside for 5 continuous months and showed no visible signs of corrosion.

Ease of Application and Curing

TC-5001 is amenable to dipping, brushing, and spraying. The ease of application of the coating is illustrated in the following video: Applying TC-5001

Methods of Application

Spraying: The coating is applied on clean surfaces using a commercial high volume, low pressure (HVLP) spray gun. Touchup spraying can be carried out to protect small pieces or tight locations using a touch up sprayer.

Rolling: Coating is done in a cross-pattern; left to right, then up and down as quickly as possible since the coating dries quickly.

Brushing: Brush application is carried out in a cross-pattern; up and down, then left to right.

.

Faster Curing

A new development that was requested by metal finishers was to accelerate the curing of TC-5001. For applications requiring faster cure times, the coating can be brought to "dry to the touch" conditions in a matter of 5 to 10 seconds with thermal curing at 150°C to 200°C. This facilitates easy incorporation of the coating in a production line with continuous moving parts on a conveyer. Once the coating is dry to touch (partially cured), subsequent coatings can be applied and cured together.

.

Related Products

NANOMYTE® PT-100 - Self-healing Pretreatment

This waterborne pretreatment improves adhesion and minimizes white & red rust formation when used in conjunction with TC-5001.

NANOMYTE® SR-500EC - Introduction of Hydrophobicity

In order to further enhance the degree of protection provided to metal parts, NANOMYTE® SR-500EC has been introduced. It is a transparent coating designed to provide easy-to-clean surfaces. The product is a nanostructured composite consisting of organic and inorganic phases and provides a hard, dense, and smooth coating finish. SR-500EC strongly adheres to metal, glass, and ceramic surfaces, and resists scratching and chipping. Additionally, it has superior water repellency and soil resistance. The hydrophobicity of the coating can be tailored as per application requirements. The coating is a single component product that is easily applied by dip, spray or brush and can be cured at room temperature. Currently, SR-500EC is undergoing field trials on metal, glass, and polymer surfaces where both anti-corrosion and hydrophobic properties are desired.

####

About NEI Corporation

NEI Corporation is an application-driven company that utilizes nanotechnology to develop and produce advanced materials. The company’s core competencies are in synthesizing nanoscale materials and prototyping products that incorporate the advanced materials. NEI offers an array of Advanced Protective Coatings for metal and polymer surfaces. The coatings have tailored functionalities such as anti-corrosion, self-healing, scratch resistance, ice-phobic, and self-cleaning.

For more information, please click here

Contacts:

Ms. Krista Martin

Engineering, Marketing, & Sales Support

400 Apgar Drive, Unit E

Somerset, NJ 08873 - USA

Office: (732) 868-3141

Fax: (732) 868-3143

Copyright © NEI Corporation

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Products

![]() Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

Spectradyne Partners with Particle Technology Labs for Measurement Services December 6th, 2018

![]() Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

Mode-Changing MEMS Accelerometer from STMicroelectronics Combines High Measurement Resolution and Ultra-Low Power for Industrial Applications November 7th, 2018

![]() Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

Fat-Repellent Nanolayers Can Make Oven Cleaning Easier October 17th, 2018

![]() Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Aculon, Inc. Enters into Strategic Partnership Agreement with Henkel Corporation to Supply Key Mobile Device Manufacturers with NanoProof® PCB Waterproof Technology October 17th, 2018

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Industrial

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||