Home > Press > Graphene layers dramatically reduce wear and friction on sliding steel surfaces

|

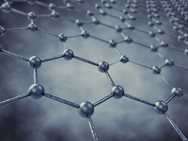

| Graphene's hexagonal structure makes it an excellent lubricant. |

Abstract:

Sometimes, all it takes is an extremely small amount of material to make a big difference.

Scientists at Argonne National Laboratory have recently discovered that they could substitute one-atom-thick graphene layers for oil-based lubricants on sliding steel surfaces, enabling a dramatic reduction in the amount of wear and friction.

Graphene layers dramatically reduce wear and friction on sliding steel surfaces

Argonne, IL | Posted on April 26th, 2013New studies led by Argonne materials scientists Anirudha Sumant and Ali Erdemir showed that graphene is able to drastically reduce the wear rate and the coefficient of friction (COF) of steel. The marked reductions in friction and wear are attributed to the low shear and highly protective nature of graphene, which also prevented oxidation of the steel surfaces when present at sliding contact interfaces.

Stainless steel ball bearings form an integral part of many moving mechanical machines, ranging from table fans to giant wind turbines.

"Reducing energy and materials losses in these moving mechanical systems due to friction and wear remains one of the greatest engineering challenges of our time," Sumant said.

Current lubricants reduce friction and wear either through the use of environmentally unfriendly additives, or in some cases, solid lubricants such as molybdenum disulfide or boric acid. The oil-based lubricants need to be consistently reapplied, producing additional waste. The cost of applying solid lubricant coatings is rather high and due to finite thickness, they do not last very long and must also be expensively reapplied.

On the other hand, coatings made of graphene flakes are not harmful to the environment and can last a considerable length of time due to the flakes' ability to reorient themselves during initial wear cycles, providing a low COF during sliding.

Sumant and Erdemir estimated that the reduced loss of energy to friction offered by new materials would yield a potential energy savings of 2.46 billion kilowatt-hours per year, equivalent to 420,000 barrels of oil.

"Applying or reapplying the graphene coating does not require any additional processing steps other than just sprinkling a small amount of solution on the surface of interest, making this process simple, cost-effective, and environmentally friendly," said Diana Berman, a postdoctoral researcher at Argonne's Center for Nanoscale Materials (CNM).

"It is interesting to see how a one-atom-thick material affects the properties at a larger scale," Sumant said. "I believe that graphene has potential as a solid lubricant in the automotive industry and, once fully developed, it could have positive impacts on many mechanical applications that could lead to a tremendous savings of energy."

Sumant is associated with Argonne's CNM, while Erdemir works for Argonne's Energy Systems Division. Funding came from Argonne's Laboratory-Directed Research and Development office.

The team recently published their findings in two consecutive papers in the high impact journal Carbon:

D. Berman, A. Erdemir, A.V. Sumant: "Few layer graphene to reduce wear and friction on sliding steel surfaces". Carbon, 54, 454-459 (2013)

D. Berman, A. Erdemir, A.V. Sumant: "Reduced Wear and Friction Enabled by Graphene Layers on Sliding Steel Surfaces in Dry Nitrogen," Carbon, in press.

####

About Argonne National Laboratory

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy's Office of Science.

The Center for Nanoscale Materials at Argonne National Laboratory is one of the five DOE Nanoscale Science Research Centers (NSRCs), premier national user facilities for interdisciplinary research at the nanoscale, supported by the DOE Office of Science. Together, the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process, characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE’s Argonne, Brookhaven, Lawrence Berkeley, Oak Ridge, Sandia and Los Alamos National Laboratories.

For more information, please click here

Contacts:

Jared Sagoff

(630) 252-5549

Copyright © Argonne National Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Laboratories

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||