Home > Press > Dripping faucets inspire new way of creating structured particles: Researchers find new method for making spherical particles, from nanoscale to pinhead-sized — including complex beach-ball-like shapes

|

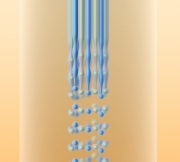

| This illustration shows how a molten fiber, because of a phenomenon known as Rayleigh instability, naturally breaks up into spherical droplets. Researchers from MIT and UCF have figured out how to use this natural tendency as a way to make large quantities of perfectly uniform particles, which can have quite complex structures. Image: Yan Liang/Fink Lab |

Abstract:

Researchers at MIT and the University of Central Florida (UCF) have developed a versatile new fabrication technique for making large quantities of uniform spheres from a wide variety of materials — a technique that enables unprecedented control over the design of individual, microscopic particles. The particles, including complex, patterned spheres, could find uses in everything from biomedical research and drug delivery to electronics and materials processing.

Dripping faucets inspire new way of creating structured particles: Researchers find new method for making spherical particles, from nanoscale to pinhead-sized — including complex beach-ball-like shapes

Cambridge, MA | Posted on July 18th, 2012The method is an outgrowth of a technique for making long, thin fibers out of multiple materials, developed over the last several years at MIT by members of the same. The new work, reported this week in the journal Nature, begins by making thin fibers using this earlier method, but then adds an extra step of heating the fibers to create a line of tiny spheres — like a string of pearls — within these fibers.

Conventional fabrication of microscopic spherical particles uses a "bottom-up" approach, growing the spheres from even tinier "seeds" — an approach that is only capable of producing very tiny particles. This new "top-down" method, however, can produce spheres as small as 20 nanometers (about the size of the smallest known viruses) or as large as two millimeters (about the size of a pinhead), meaning the biggest particles are 100,000 times larger than the smallest ones. But for a given batch, the size of the spheres produced can be extremely uniform — much more so than is possible with the bottom-up approach.

Yoel Fink, a professor of materials science and director of MIT's Research Laboratory of Electronics, whose group developed the earlier method of producing multimaterial fibers, explains that the new method can also produce multimaterial spheres consisting of different layers or segments. Even more complex structures are possible, he says, offering unprecedented control over particle architecture and composition.

The most likely short-term uses of the new process would be for biomedical applications, says Ayman Abouraddy, a former postdoc in Fink's lab who is now an assistant professor at UCF's College of Optics and Photonics. "Typical applications of nanoparticles today are for controlled drug delivery," he says. But with this new process, two or more different drugs — even ones that are ordinarily incompatible — could be combined inside individual particles, and released only once they've reached their intended destination in the body.

More exotic possibilities could arise later, Abouraddy adds, including new "metamaterials" with advanced optical properties that were previously unattainable.

The basic process involves creating a large polymer cylinder, called a "preform," containing an internal semiconductor cylinder core that is an exact scaled-up model of the final fiber structure; this preform is then heated until it is soft enough to be pulled into a thin fiber, like taffy. The internal structure of the fiber, made of materials that all soften at the same temperature, retains the internal configuration of the original cylinder.

The fiber is then heated further so that the semiconducting core forms a liquid, producing a series of discrete spherical droplets within the otherwise continuous fiber. This same phenomenon causes a diminishing stream of water from a faucet to eventually break up into a stream of droplets, famously captured by MIT's Harold "Doc" Edgerton in his stroboscopic images.

Abouraddy says that during a visit to ancient temples in his native Egypt, he found an inscription showing that even long ago, people were aware of this degradation of a stream of water into droplets — caused by a process now known as Rayleigh instability.

In the new fabrication process developed by Abouraddy and Fink's team, these droplets "freeze" in place as the fiber solidifies; the preform's polymer sheath then keeps them locked in place until it is later dissolved away. This overcomes another problem with traditional production of nanoparticles: their tendency to clump together.

In principle, Abouraddy says, the discovery of this process for forming particles could have come many years ago. But even after theorists had predicted that such instabilities could form in the process of drawing fibers, the new discovery came by accident: Joshua Kaufman, a student of Abouraddy's, was trying to produce fibers, but his experiment "failed" when the fiber kept breaking up into droplets.

Abouraddy, who knew about the theoretical possibility, immediately recognized that this "failure" was actually an important discovery — one that had eluded previous attempts simply because the process requires a precise combination of timing, temperature and materials. Kaufman is the lead author of the Nature paper.

"The ability to harness and control the fleeting fluid instability within a fiber has profound implications for future devices," Fink says, and could lead to a wide variety of uses. While the group has demonstrated the production of six-segment "beach ball" particles, in principle much more complex structures, made of a variety of materials, should also be possible, he says. Any material that could be drawn into a fiber could now, in principle, be made into a small particle.

The work was supported by the National Science Foundation, the Air Force Office of Scientific Research and the Army Research Office through MIT's Institute for Soldier Nanotechnologies.

Written by David Chandler, MIT News Office

####

For more information, please click here

Contacts:

Sarah McDonnell

MIT News Office

T: 617-253-8923

Copyright © MIT

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Military

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

What heat can tell us about battery chemistry: using the Peltier effect to study lithium-ion cells March 8th, 2024

![]() New chip opens door to AI computing at light speed February 16th, 2024

New chip opens door to AI computing at light speed February 16th, 2024

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||