Home > Press > Graphene-control cutting using an atomic force microscope-based nanorobot

|

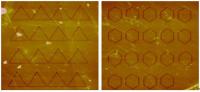

| This shows graphene cutting results based on a nanorobot.

Credit: ©Science China Press |

Abstract:

Graphene, a stable two-dimensional structure, has attracted tremendous worldwide attention in recent years because of its unique electronic, physical and mechanical properties as well as its wide range of applications. It has been proven experimentally that the electrical properties of graphene are strongly related to its size, geometry, and edge structure. Therefore, controlling graphene to desired edge structures and shapes is required for its practical application. To date, researchers have explored many graphene patterning methods, such as a catalytic cutting [1-4], SPM(Scanning Probe Microscopy)-based electric field tailoring [5-7], energy beam cutting [8-10] and photocatalytic patterning techniques [11]. The current methods can tailor graphene, however, lack of real-time sensor feedback during patterning and cutting results in an open-loop manufacturing process. This greatly limits the cutting precision of graphene and reduces the efficiency of device manufacture. Therefore, a closed-loop fabrication method using interaction forces as real-time feedback is needed to tailor graphene into desired edge structures and shapes in a controllable manner.

Graphene-control cutting using an atomic force microscope-based nanorobot

PR China | Posted on May 27th, 2012Professor LIU Lianqing from the State Key Laboratory of Robotics, Shenyang Institute of Automation Chinese Academy of Sciences and Professor XI Ning from the Department of Electrical and Computer Engineering, Michigan State University undertook the background research to overcome this challenge. Their work, entitled "Graphene Control Cutting Using an Atomic Force Microscope Based NanoRobot", was published in SCIENTIA SINICA Physica, Mechanica & Astronomica. 2012, Vol 42(4). They investigated controlled cutting methods of graphene based on nanoscale force feedback by the introduction of robot perception, drivers and behavior coupled with an atomic force microscope. They found that the cutting forces were related to the cutting direction of the graphene lattice because of the asymmetry of the crystal structure of graphene. This discovery is expected to allow nanoscale forces to be used as real-time feedback to establish a closed-loop mechanism to cut graphene with precise control.

Atomic force microscopy is only a nanoscale observation tool, and its main shortcomings are poor location ability, lack of real-time feedback, and low efficiency. These challenges are solved by the introduction of robotics that is efficient at nanomanipulation. In this article, the relationship between lattice cutting directions and nanocutting forces were studied systematically by rotating the sample under the same cutting conditions (load, cutting velocity, tip, and effective cutting surface of the tip). The experimental results show that the cutting force is related to the lattice cutting direction: the cutting forces vary with cutting direction in the same period with a difference of up to around 209.36 nN.

This article is the first to show that cutting forces vary with lattice cutting directions, which lays an experimental foundation to build a closed-loop fabrication strategy using real-time force as a sensor feedback to control the cutting direction with lattice precision. Combined with existing parallel multi-tip technology, the technique developed in this work will make it possible to fabricate large-scale graphene-based nanodevices at low cost with high efficiency. This research was supported by the National High Technology Research and Development Program of China (Grant No. 2009AA03Z316), the National Natural Science Foundation of China (Project Nos. 60904095, 51050110445, and 61175103), and the CAS/SAFEA (Chinese Academy of Sciences/State Administration of Foreign Experts Affairs) International Partnership Program for Creative Research Teams.

See the article: Zhang Y, Liu L Q, Xi N, et al. Graphene Control Cutting Using an Atomic Force Microscope Based NanoRobot (In Chinese). SCIENTIA SINICA Physica, Mechanica & Astronomica, 2012, 42(4):358

References

[1] Datta, S S.et al. Crystallographic Etching of Few-Layer Graphene. Nano Lett, 8, 1912-1915 (2008).

[2] Ci, L. et al. Controlled nanocutting of graphene. Nano Research, 1, 116-122 (2008).

[3] Campos, L. C. et al. Anisotropic Etching and Nanoribbon Formation in Single-Layer Graphene. Nano Lett, 9, 2600-2604 (2009).

[4] Gao, L. et al. Crystallographic Tailoring of Graphene by Nonmetal SiOx Nanoparticles. J. Am. Chem. Soc, 131, 13934-13936 (2009).

[5] Giesbers, A. J. M. et al. Nanolithography and manipulation of graphene using an atomic force microscope. Sol. St. Comm, 147, 366-369 (2008).

[6] Tapaszto, L., Dobrik, G., Lambin, P. & Biro, L. P. Tailoring the atomic structure of graphene nanoribbons by scanning tunnelling microscope lithography. Nat Nano, 3, 397-401 (2008).

[7] Weng, L., Zhang, L.Y., Chen, Y. P. & Rokhinson L.P. et al. Atomic force microscope local oxidation nanolithography of graphene. Appl. Phys. Lett, 93, 093107 (2008)

[8] Fischbein, M. D. & Drndic, M. Electron beam nanosculpting of suspended graphene sheets. Appl. Phys. Lett, 93, 113107 (2008).

[9] Bell, D. C., Lemme, M. C., Stern, L. A. & Marcus, C. M. Precision cutting and patterning of graphene with helium ions. Nanotechnology, 20, 455301(2009).

[10] Lemme, M. C., Bell, D. C., Williams, J. R. Etching of Graphene Devices with a Helium Ion Beam. ACS Nano, 3, 2674-2676(2009).

[11] Zhang, L.M., et al. Photocatalytic Patterning and Modification of Graphene. J. Am. Chem.Soc. 133, 2706-2713(2011)

####

For more information, please click here

Contacts:

LIU Lianqing

Copyright © Science in China Press

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Graphene/ Graphite

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Molecular Nanotechnology

![]() Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

![]() Nanotech scientists create world's smallest origami bird March 17th, 2021

Nanotech scientists create world's smallest origami bird March 17th, 2021

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||