Home > Press > Toyohashi Tech researchers develop a low cost and efficient method for producing electrically conducting composites based on electrostatic adsorption of CNTs onto resin and ceramic particles for applications including the production of enzymes and cosmetics.

|

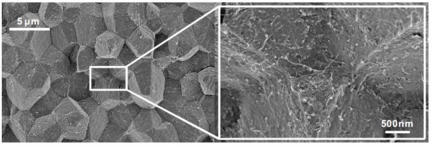

| Cross-section of PMMA resin composite material showing the networks of CNTs on the surfaces of the resin particles. The CNTs are added to induce electrical conductivity. |

Abstract:

Hiroyuki Muto and colleagues at Japan's Toyohashi University of Technology (Toyohashi Tech) have developed an innovative method for producing CNT (carbon nano-tube) resin composite material [1] that only requires 1/100 [2] of the conventional amount of CNT additive to produce electrical conductivity in the composite material.

Toyohashi Tech researchers develop a low cost and efficient method for producing electrically conducting composites based on electrostatic adsorption of CNTs onto resin and ceramic particles for applications including the production of enzymes and cosmetics.

Toyohashi, Japan | Posted on September 4th, 2011In this method, CNTs were mixed in an electrolyte solution and added to the composite, where the CNTs were adsorbed onto the surfaces of the resin particles due to electrostatic adsorption [3]. This innovative procedure enabled the production of electrical conducting composites by the addition of a small quantity CNTs.

Importantly, the electrical conductivity of the composite material was easily controlled by changing the amount of electrolyte added to the composite; namely, the concentration of CNTs adsorption onto the resin particles.

Notably, this approach enables significant reductions in both the production costs and the production time compared with conventional methods for manufacturing conductive resins.

The researchers are confident that adding particles with charged surfaces will enable the production of a wide range of composite materials such as metals, ceramics, and polymers. This method is expected to find applications in the production of enzymes and cosmetics.

This work is supported by a Grant-in-Aid for Young Scientists at NEDO (New Energy and Industrial Technology Development Organization).

[1] This is a composite material comprising of resin particle with the addition CNTs. By utilizing the high conductivity of CNTs, practical products such as robust, anti-static components for clean rooms in the electronics industry, could be manufactured. The ability to control the electrical conductivity of the composite materials by this production method is expected to lead to a wide range of applications in the electronics industry, including use as alternatives for indium-tin-oxide transparent conductive film for displays, as plates for rechargeable batteries, and in semiconductor devices. Furthermore, the composite resin particles can be used in the production of for plastic materials, such as injection molding or extrusion.

[2] When imparting electrical conductivity to insulating ceramics or polymer materials, the introduction of conducting additive materials that can be linked within the resin structure is required. In conventional methods, the amount of additive is greater than 1% by weight. However, this new method only requires the addition of 0.01% CNT to impart conductivity.

[3] This method adsorbs CNTs onto the matrix resin particles by an electrostatic attractive force, which is a result of charging them positive or negative in appropriate electrolyte solutions. By controlling the concentration of the electrolyte solution added to the composite, the charge-volume of the surfaces of the particles can be changed, thus controlling the degree of adsorption of the CNTs.

####

About Toyohashi University of Technology

Founded in 1976, Toyohashi University of Technology is a vibrant modern institute with research activities reflecting the modern era of advanced electronics, engineering, and life sciences.

For more information, please click here

Contacts:

Ms. Junko Sugaya and Mr. Masashi Yamaguchi

International Affairs Division

TEL: (+81) 0532-44-2042; FAX: (+81)0532-44-6557

Copyright © Toyohashi University of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Personal Care/Cosmetics

![]() DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

DGIST and New Life Group launched a research project on "Functional beauty and health products using the latest nanotechnology" May 12th, 2023

![]() A Comprehensive Guide: The Future of Nanotechnology September 13th, 2018

A Comprehensive Guide: The Future of Nanotechnology September 13th, 2018

![]() Graphene finds new application as anti-static hair dye: New formula works as well as commercial permanent dyes without chemically altering hairs March 22nd, 2018

Graphene finds new application as anti-static hair dye: New formula works as well as commercial permanent dyes without chemically altering hairs March 22nd, 2018

![]() Programmable materials find strength in molecular repetition May 23rd, 2016

Programmable materials find strength in molecular repetition May 23rd, 2016

Nanobiotechnology

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

Ben-Gurion University of the Negev researchers several steps closer to harnessing patient's own T-cells to fight off cancer June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||