Home > Press > Ions Control Shape Of Nanofibers Grown On Clear Substrate

|

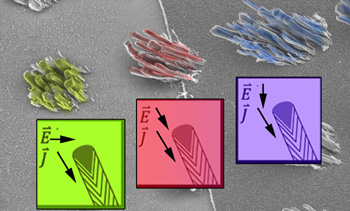

| The nanofibers lean in different directions depending on where they are located in relation to the chromium grid, because the ions are being drawn to the grid and strike the catalysts at various angles. |

Abstract:

"Role of ion flux on alignment of carbon nanofibers synthesized by DC plasma on transparent insulating substrates"

Authors: Ryan C. Pearce, Anatoli V. Melechko, North Carolina State University; Alexei V. Vasenkov, CFDRC; Dale K. Hensley, Michael L. Simpson, Timothy E. McKnight, Oak Ridge National Laboratory

Published: Forthcoming from the ACS journal Applied Materials & Interfaces

Abstract: A key factor to the implementation of devices with vertically aligned carbon nanofibers (VACNFs) is fundamental understanding of how to control fluctuations in the growth direction of the fibers. Here we demonstrate synthesis of VACNF on transparent and insulating substrates by continuous direct current plasma for realization of cellular interface suitable for transmission optical microscopy. To maintain continuous glow discharge above the substrate, a metal grid electrode layer was deposited over silica with windows of exposed silica ranging in size from 200?m to 1mm. This electrode geometry allows for synthesis of VACNFs even within an insulating window. This observation and the observed trends in the alignment of nanofibers in the vicinity of grid electrodes have indicated that the alignment does not correspond to the direction of the electric field at the substrate level, contrary to previously proposed alignment mechanism. Computational modeling of the plasma with this grid cathode geometry has shown that nanofiber alignment trends follow calculated ion flux direction rather than electrical field. The new proposed alignment mechanism is that ion sputtering of the carbon film on a catalyst particle defines the growth direction of the nanofibers. With this development, fiber growth direction can be better manipulated through changes in ionic flux direction, opening the possibility for growth of nanofibers on substrates with unique geometries.

Ions Control Shape Of Nanofibers Grown On Clear Substrate

Raleigh, NC | Posted on August 16th, 2011Researchers from North Carolina State University, the Oak Ridge National Laboratory and CFD Research Corporation have found a new way to develop straight carbon nanofibers on a transparent substrate. Growing such nanofiber coatings is important for use in novel biomedical research tools, solar cells, water repellent coatings and others. The technique utilizes a charged chromium grid, and relies on ions to ensure the nanofibers are straight, rather than curling - which limits their utility.

"This is the first time, that I know of, where someone has been able to grow straight carbon nanofibers on a clear substrate," says Dr. Anatoli Melechko, an associate professor of materials science and engineering at NC State and co-author of a paper describing the research. "Such nanofibers can be used as gene-delivery tools. And a transparent substrate allows researchers to see how the nanofibers interact with cells, and to manipulate this interaction."

Specifically, the nanofibers can be coated with genetic material and then inserted into the nucleus of a cell - for example, to facilitate gene therapy research. The transparent substrate improves visibility because researchers can shine light through it, creating better contrast and making it easier to see what's going on.

The researchers also learned that ions play a key role in ensuring that the carbon nanofibers are straight. To understand that role, you need to know how the technique works.

The nanofibers are made by distributing nickel nanoparticles evenly on a substrate made of fused silicon (which is pure silicon dioxide). The substrate is then overlaid with a fine grid made of chromium, which serves as an electrode. The substrate and grid are then placed in a chamber at 700 degrees Celsius, which is then filled with acetylene and ammonia gas. The chrome grid is a negatively charged electrode, and the top of the chamber contains a positively charged electrode.

Electric voltage is then applied to the two electrodes, creating an electric field in the chamber that excites the atoms in the acetylene and ammonia gas. Some of the electrons in these atoms break away, creating free electrons and positively charged atoms called ions. The free electrons accelerate around the chamber, knocking loose even more electrons. The positively charged ions are drawn to the negatively charged grid on the floor of the chamber.

Meanwhile, the nickel nanoparticles are serving as catalysts, reacting with the carbon in the acetylene gas (C2H2) to create graphitic carbon nanofibers. The catalyst rides on the tip of the nanofiber that forms beneath it, like a rapidly growing pillar. The term graphitic means that the nanofibers have carbon atoms arranged in a hexagonal structure - like graphite.

One problem with growing carbon nanofibers is that the surface of the catalyst can become obstructed by a carbon film that blocks catalytic action, preventing further nanofibers growth. Here's where those ions come in.

The ions being drawn to the chromium grid are moving very quickly, and they choose the shortest possible route to reach the negatively-charged metal. In their rush to reach the grid, the ions often collide with the nickel catalysts, knocking off the excess carbon - and allowing further nanofibers growth. Video of the process is available here.

Because the ions are being drawn to the chromium grid, the angle at which they strike the catalysts depends on where the catalyst is located relative to the grid. For example, if you are looking down at the grid, a catalyst just to the right of the grid will appear to be leaning right - because ions would have been striking the right side of the catalyst in an attempt to reach the grid. These nanofibers are still straight - they don't curl up - they simply lean in one direction. The bulk of the nanofibers, however, are both straight and vertically aligned.

"This finding gives us an opportunity to create new reactors for creating nanofibers, building in the chromium grid," Melechko says.

The paper, "Role of ion flux on alignment of carbon nanofibers synthesized by DC plasma on transparent insulating substrates," is forthcoming from the ACS journal Applied Materials & Interfaces. The paper was co-authored by Ryan Pearce, a Ph.D. student at NC State; Dr. Alexei Vasenkov of CFDRC; and Dale Hensley, Dr. Michael Simpson and Timothy McKnight of Oak Ridge National Laboratory. The research was supported by Materials Sciences and Engineering Division, Office of Basic Energy Sciences, U.S. Department of Energy (processing, analytical microscopy, and experimental design). The device fabrication for cell interfacing was done through a user project at the Center for Nanophase Materials Sciences, Oak Ridge National Laboratory, and sponsored by the Scientific User Facilities Division, Office of Basic Energy Sciences, U.S. Department of Energy.

NC State's Department of Materials Science and Engineering is part of the university's College of Engineering.

-shipman-

####

For more information, please click here

Contacts:

Matt Shipman | News Services | 919.515.6386

Dr. Anatoli Melechko

919.515.8636

Copyright © North Carolina State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Laboratories

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

![]() NRL discovers two-dimensional waveguides February 16th, 2024

NRL discovers two-dimensional waveguides February 16th, 2024

![]() Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

Three-pronged approach discerns qualities of quantum spin liquids November 17th, 2023

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Research partnerships

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() 'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

'Sudden death' of quantum fluctuations defies current theories of superconductivity: Study challenges the conventional wisdom of superconducting quantum transitions January 12th, 2024

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||