Home > Press > Research: Electric Fields Make Ceramic Production Quicker, Cheaper

|

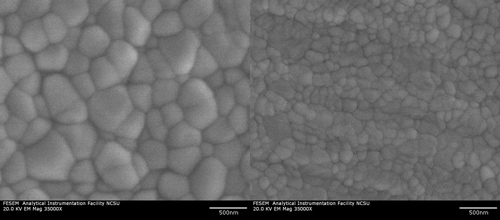

| By applying a 60 Hertz alternating current (AC) field, researchers were able to reduce the grain size of ceramics by 63 percent - and eliminated porosity at 1,250 degrees Celsius, as opposed to the 1,500 degrees Celsius needed without the electric field. |

Abstract:

Researchers from North Carolina State University have found that applying a small electric field results in faster formation of ceramic products during manufacture at lower temperatures, and enhances the strength of the ceramic itself.

By Matt Shipman

Research: Electric Fields Make Ceramic Production Quicker, Cheaper

Raleigh, NC | Posted on June 2nd, 2010At issue is a process called sintering, which is how most ceramic products are made. The process involves taking fine ceramic powder, compressing it into the desired shape of the final product, and heating it. Under high heat, the atoms of the powder material bond by diffusion - meaning the atoms of different powder grains move around, bonding the fine powder particles together. Sintering eliminates porosity in the ceramic product, which significantly strengthens the material.

"By applying a 60 Hertz alternating current (AC) field, we were able to eliminate porosity at 1,250 degrees Celsius - as opposed to the 1,500 degrees Celsius needed without the electric field," says Dr. Hans Conrad, emeritus professor of materials science and engineering at NC State and co-author of the study. In addition, the researchers were able to reduce the grain size of the ceramic by 63 percent - creating grains with a diameter of 134 nanometers (nm), as opposed to the 360 nm diameter grains produced using conventional sintering methods. Smaller grain size makes a ceramic stronger, because the larger a grain is, the easier it is for cracks to both form and spread.

Ceramics make up significant components of an array of products, including insulators, spark plugs, fuel cells, body armor, gas turbines, nuclear rods, high temperature ball bearings, high temperature structural materials and heat shields.

The researchers were able to achieve similar, but less significant, results using an electric field created by direct current (DC). Porosity was eliminated at 1,400 degrees Celsius using DC, and grain size was reduced to a diameter of 217 nm - both still dramatic improvements over current sintering techniques. The field used for both AC and DC fields was 13.9 volts/cm.

"We found that the use of a small electric field - with a current of only six-tenths to eight-tenths of an amp per centimeter squared - can result in improved sintering rates with much finer grain size," Conrad says. In other words, ceramics manufacturers can make their products more quickly and cheaply by using an inexpensive electric field - and make their product stronger as well.

"You don't use much energy, and you put it right at the atomic site where it is needed - rather than using more energy to create higher temperatures in a kiln, which is less efficient," Conrad says. "If you want to make a strong ceramic, you want to eliminate porosity and keep the grain size as small as possible. And you want to do it at the lowest cost - which means using the smallest amount of energy and doing it at the lowest temperature at the fastest rate possible. Using an electric field achieves all of these goals."

The research is described in "Enhanced sintering rate of zirconia (3Y-TZP) by application of a small AC electric field," which will be published in a forthcoming issue of Scripta Materialia. The lead author of the paper is Dr. Di Yang, a senior research associate at NC State. This research stemmed from previous work by Yang and Conrad that was funded by the U.S. Army Research Office.

Conrad and Yang are currently working to determine the effects of the frequency and strength of the electric field and to investigate other ceramic materials.

The Department of Materials Science and Engineering is part of NC State's College of Engineering.

The study abstract follows

"Enhanced sintering rate of zirconia (3Y-TZP) by application of a small AC electrical field"

Authors: Di Yang, Hans Conrad North Carolina State University

Published: forthcoming, 2010, Scripta Materialia

Abstract: A small initial electric field E0= 13.9V/cm enhanced the sintering rate of zirconia(3Y-TZP) powder, with a 60Hz AC field having a greater effect than a DC field. The enhancement with both fields was in accord with the retardation of grain growth observed directly with SEM and with that which occurred during grain growth and plastic deformation. Some factors which could contribute to the observed behavior are given.

####

For more information, please click here

Contacts:

Matt Shipman

News Services

919.515.6386

Dr. Hans Conrad

919.515.7443

Copyright © North Carolina State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||