Home > Press > Surface engineering: Imprinted cleanliness

|

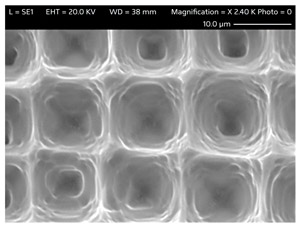

| Fig. 1: Etching a dense array of pits into the surface of a silicon substrate with a laser increases its water repellency. Using this surface as a template to imprint the reverse of this pattern into a sol–gel film results in a surface that is even more water repellent. © 2009 A*STAR |

Abstract:

A laser-patterned template could enable self-cleaning surfaces to be grown over large areas at low cost.

Surface engineering: Imprinted cleanliness

Singapore | Posted on December 9th, 2009The leaves of the lotus flower have a remarkable property—they are self-cleaning. Because the leaves are hydrophobic, or water repellent, water that comes into contact with them forms spherical beads that roll along the leaf picking up dust and dirt on from its surface. Now, a research group from the Singapore Institute of Manufacturing Technology of A*STAR have developed a method that could eventually enable large surface areas to be coated with a hydrophobic layer that mimics this self-cleaning property (1).

"Hydrophobic surfaces are desirable for many industrial applications such as anti-biofouling paints for boats, anti-sticking of snow for antennas and windows, self-cleaning windshields for automobiles, stain-resistant textiles and anti-soiling architectural coatings," explains Xincai Wang from the group.

Many techniques exist for making a surface hydrophobic. Coating a surface with chemicals that are naturally water repellent, for example, is one approach. However, this may not work for many surfaces. Moreover, such chemicals gradually degrade and are easily rubbed off, requiring continual retreatment. A more robust and longer-lasting approach is to change the microscopic structure of a surface. It is well known that structuring a surface to have micrometer-sized protrusions increases its water-repelling properties. But conventional techniques for patterning these structures, such as photolithography combined with reactive ion etching, are time-consuming and expensive.

The technique developed by Wang and co-workers produces hydrophobic surfaces that are robust and potentially much cheaper than those produced by photolithgraphic patterning. First, the researchers drilled a dense array of pits into a flat silicon substrate with a sharply focused, ultraviolet laser (Fig. 1). They found that this step on its own increased the hydrophobicity of the surface, causing water droplets on its surface to form a more spherical shape than on an untreated surface. Such behavior is typically quantified by measuring the angle made by the base of a droplet with the surface, known as the wetting angle, which in this case increased from 64.2° to 97.5°.

Next, Wang and co-workers used the silicon surface as a stamp to imprint the inverse of its pattern into the surface of a soft sol-gel film. Without modification, these films exhibited hydrophibicity with a contact angle of 110°. But imprinting them with the silicon stamp increased this to 138°.

In future work, the researchers intend to extend this approach to make hydrophobic surfaces over large areas on an industrial scale.

The A*STAR affiliated authors in this highlight are from the Singapore Institute of Manufacturing Technology

Reference

1 Wang, X.C., Wu, L.Y.L., Shao, Q. & Zheng, H.Y. Laser micro structuring on a Si substrate for improving surface hydrophobicity. Journal of Micromechanics and Microengineering 19, 085025 (2009).

####

About A*STAR

A*STAR Research is an online and print publication highlighting some of the best research and technological developments at the research institutes of Singapore’s Agency for Science, Technology and Research (A*STAR). Established in 2002, A*STAR has thrived as a global research organization with a principal mission of fostering world-class scientific research and talent for a vibrant knowledge-based Singapore. A*STAR currently oversees 14 research institutes as well as 7 consortia and centers located in the Biopolis and Fusionopolis complexes and the vicinity, and supports extramural research in collaboration with universities, hospital research centers and other local and international partners. The various A*STAR institutes are involved in research in a wide range of scientific fields, coordinated and funded by Singapore’s Biomedical Research Council (BMRC) and Science and Engineering Research Council (SERC).

For more information, please click here

Copyright © A*STAR

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Marine/Watercraft

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

Quantum tech in space? Scientists design remote monitoring system for inaccessible quantum devices February 11th, 2022

![]() Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes March 3rd, 2021

Expanding the freedom of design: powder coating on FRP thanks to conductive gelcoats with graphene nanotubes March 3rd, 2021

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Environment

![]() Billions of nanoplastics released when microwaving baby food containers: Exposure to plastic particles kills up to 75% of cultured kidney cells July 21st, 2023

Billions of nanoplastics released when microwaving baby food containers: Exposure to plastic particles kills up to 75% of cultured kidney cells July 21st, 2023

Construction

![]() Temperature-sensing building material changes color to save energy January 27th, 2023

Temperature-sensing building material changes color to save energy January 27th, 2023

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||