Home > Press > Lasers Used to Make First Boron-Nitride Nanotube Yarn

|

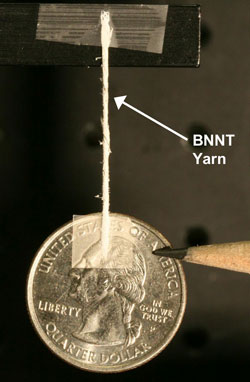

| A yarn spun of boron-nitride nanotubes suspends a quarter. |

Abstract:

Researchers have used lasers to create the first practical macroscopic yarns from boron nitride fibers, opening the door for an array of applications, from radiation-shielded spacecraft to stronger body armor, according to a just-published study.

Lasers Used to Make First Boron-Nitride Nanotube Yarn

Newport New, VA | Posted on December 4th, 2009Researchers at NASA's Langley Research Center, the Department of Energy's Thomas Jefferson National Accelerator Facility and the National Institute of Aerospace created a new technique to synthesize high-quality boron-nitride nanotubes (BNNTs). They are highly crystalline and have a small diameter. They also structurally contain few walls and are very long. Boron nitride is the white material found in clown make-up and face powder.

"Before, labs could make really good nanotubes that are are short or really crummy ones that are long. We've developed a technique that makes really good ones that are really long," said Mike Smith, a staff scientist at NASA's Langley Research Center.

The synthesis technique, called the pressurized vapor/condenser (PVC) method, was developed with Jefferson Lab's Free-Electron Laser and later perfected using a commercial welding laser. In this technique, the laser beam strikes a target inside a chamber filled with nitrogen gas. The beam vaporizes the target, forming a plume of boron gas. A condenser, a cooled metal wire, is inserted into the boron plume. The condenser cools the boron vapor as it passes by, causing liquid boron droplets to form. These droplets combine with the nitrogen to self-assemble into BNNTs.

Researchers used the PVC method to produce the first high-quality BNNTs that are long enough to be spun into macroscopic yarn, in this case centimeters long. A cotton-like mass of nanotubes was finger-twisted into a yarn about one millimeter wide, indicating that the nanotubes themselves are about one millimeter long.

"They're big and fluffy, textile-like," said Kevin Jordan, a staff electrical engineer at Jefferson Lab. "This means that you can use commercial textile manufacturing and handling techniques to blend them into things like body armor and solar cells and other applications."

Transmission electron microscope images show that the nanotubes are very narrow, averaging a few microns in diameter. TEM images also revealed that the BNNTs tended to be few-walled, most commonly with two-five walls, although single-wall nanotubes were also present. Each wall is a layer of material, and fewer-walled nanotubes are the most sought after.

The researchers say the next step is to test the properties of the new boron-nitride nanotubes to determine the best potential uses for the new material. They are also attempting to improve and scale up the production process.

"Theory says these nanotubes have energy applications, medical applications and, obviously, aerospace applications," said Jordan.

Smith agreed, "Some of these things are going to be dead ends and some are going to be worth pursuing, but we won't know until we get material in people's hands."

The research will be published in the December 16 issue of the journal Nanotechnology. The article is available for a short time online. It will also be presented at the 2009 Materials Research Society Fall Meeting on December 3.

The research was supported by the NASA Langley Creativity and Innovation Program, the NASA Subsonic Fixed Wing program, DOE's Jefferson Lab and the Commonwealth of Virginia. The experiments were hosted at Jefferson Lab.

####

About Jefferson Lab

Jefferson Lab is managed and operated for the U.S. Department of Energy's Office of Science by Jefferson Science Associates, LLC, a joint venture between Southeastern Universities Research Association, Inc. and CSC Applied Technologies Division, LLC.

For more information, please click here

Contacts:

Kandice Carter

Jefferson Lab Public Affairs

757-269-7263

Copyright © Jefferson Lab

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Videos/Movies

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||