Home > Press > MIT: Spinning at the nanoscale --Electrospun fibers could be used for protective clothing, wearable power and more

|

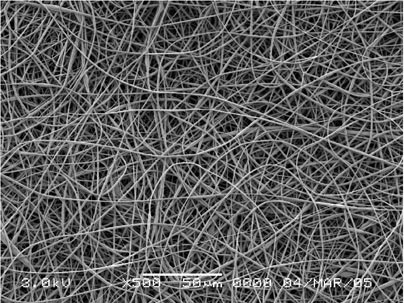

| A scanning electron micrograph of an electrospun nonwoven mat of poly(styrene-co-dimethylsiloxane) fibers, showing the porous, nonwoven structure of the mat. Image / Greg Rutledge |

Abstract:

In his office, MIT Professor of Chemical Engineering Gregory Rutledge keeps a small piece of fabric that at first glance resembles a Kleenex. This tissue-like material, softer than silk, is composed of fibers that are a thousand times thinner than a human hair and holds promise for a wide range of applications including protective clothing, drug delivery and tissue engineering.

MIT: Spinning at the nanoscale --Electrospun fibers could be used for protective clothing, wearable power and more

Cambridge, MA | Posted on May 5th, 2009Such materials are produced by electrospinning, a technique that has taken off in the past 10 years, though the original technology was patented more than a century ago. In Rutledge's lab, researchers are exploring new ways to create electrospun fibers, often incorporating materials that add novel features such as the ability to kill bacteria.

"We're still in the Wild West mode of discovery," says Rutledge. "People are hypothesizing almost anything and giving it a try. We're still trying to figure out which ones are the payoff applications."

Rutledge has been one of the pioneers of electrospinning nanofibers since the nanotechnology boom of the late 1990s. Though he describes the actual electrospinning process as almost "a mundane thing," he and his colleagues have demonstrated a number of ways to create electrospun membranes with new and useful traits.

Electrospinning, the most general way to make a continuous polymer nanofiber, uses an electrical charge to draw the fiber from a liquid polymer. As a jet of charged fluid polymer sprays out the bottom of a nozzle, an electric field forces the stream to whip back and forth, stretching the fiber lengthwise so its diameter shrinks from 100 microns to as little as 10 nanometers.

The fiber forms a thin membrane as it hits the surface below the nozzle. These electrospun membranes have a unique combination of stretchiness and strength, and are easy to handle, making them suitable for a wide range of applications. Because the membranes are very porous (they contain 85 percent open space), they are already used as HEPA (high efficiency particle accumulation) filters, found in vacuum cleaners and military tanks.

In the past few years, Rutledge's team has produced several textiles that incorporate functional materials into the electrospun membranes. One major focus is designing textiles that can protect against toxic agents, both biological and chemical, by adding protective compounds to the polymer.

One such material, described in the journal Polymer last year, incorporates chlorhexidine, which can kill most bacteria. Rutledge's team is also working with oximes, a class of organic compounds that can break down organophosphates, chemicals that are the basis of many pesticides, insecticides and nerve gases. Materials such as these, developed in collaboration with Alan Hatton, the Ralph Landau Professor of Chemical Engineering, could be used to coat medical devices or create protective clothing for soldiers.

Rutledge and Paula Hammond, the Bayer Professor of Chemical Engineering, recently reported in the journal Advanced Materials a material embedded with titanium oxide, which can break down a variety of industrial chemicals, including organic compounds like phenols and allyl alcohol.

The fibers hold promise for development of new breathable, waterproof materials. Four years ago, Rutledge and Randy Hill of Dow Corning created an electrospun sheet that is extremely water-repellent. Such a material, described in the journal Langmuir, has the potential to become a cheaper alternative to GoreTex, which is made of Teflon — a more expensive starting material than the polymers used to make electrospun fibers. More recently, working with MIT professors Karen Gleason, Robert Cohen, Gareth McKinley and Michael Rubner, Rutledge's group has demonstrated a variety of ways to render breathable electrospun fabrics water- and oil-repellent.

Rutledge is now working on electrospun fibers made of block copolymers that self-assemble into a collection of concentric cylinders within the fiber. Such fibers, made possible by a co-axial version of electrospinning technology that the group reported in 2004, could be used to impart color to fabrics without dye, or to create "wearable power" by combining electrodes and electrolytes into individual fibers.

"There are a lot of ways one can imaginatively think to use some of this stuff," says Rutledge.

Written by Anne Trafton, MIT News Office

####

About MIT

The mission of MIT is to advance knowledge and educate students in science, technology, and other areas of scholarship that will best serve the nation and the world in the 21st century.

For more information, please click here

Contacts:

Elizabeth A. Thomson

MIT News Office

617-258-5402

Copyright © MIT

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Textiles/Clothing

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

![]() Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||