Home > Press > Veeco Introduces “FastLine” Glass Coating Platform: For Production of CIGS Thin Film Solar Cells

|

Abstract:

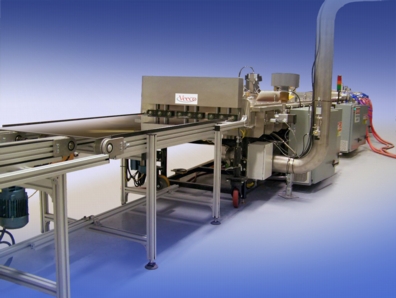

Veeco Instruments Inc. (Nasdaq: VECO), announced the introduction of its FastLine™ platform of Glass Coating Systems, leveraging Veeco's proven PV-Series™ Thermal Deposition Sources. Veeco's new FastLine platform is designed for high throughput, low cost of ownership production of CIGS (copper, indium, gallium and selenium) solar cells.

Veeco Introduces “FastLine” Glass Coating Platform: For Production of CIGS Thin Film Solar Cells

Plainview, NY | Posted on April 27th, 2009Piero Sferlazzo, Ph.D., Senior Vice President of Veeco's Solar Equipment business, commented, "Veeco is now the only equipment company offering integrated production-scale solutions for CIGS manufacturing on glass using thermal evaporation sources for the CIGS/absorber layer. Customers can now choose Veeco to provide comprehensive, fully integrated equipment to manufacture CIGS solar cells, whether they choose to use our FastLine systems for glass or our FastFlex™ systems for flexible substrates."

Thermal evaporation, as compared to other deposition methods, produces the highest efficiency thin film solar cells and has the lowest materials costs with high material utilization driving down the manufacturing cost per watt. Veeco's FastLine systems can handle up to thirty 1.1m x 1.4m glass panels/hour. The modular architecture of the system allows customers to scale their output according to their needs.

The U.S. Department of Energy's National Renewable Energy Laboratory (NREL) has claimed a world record for CIGS thin-film solar cell conversion efficiency of 19.9 percent. The conversion efficiency for CIGS is now close to that of multi-crystalline silicon-based solar cells, according to NREL. This achievement was hailed as an important milestone because the efficiency of thin film solar cells is now achieving its goal of matching silicon in performance.

####

About Veeco Instruments Inc.

Veeco Instruments Inc. manufactures enabling solutions for customers in the HB-LED, solar, data storage, semiconductor, scientific research and industrial markets. We have leading technology positions in our three businesses: LED & Solar Process Equipment, Data Storage Process Equipment, and Metrology Instruments. Veeco’s manufacturing and engineering facilities are located in New York, New Jersey, California, Colorado, Arizona, Massachusetts and Minnesota. Global sales and service offices are located throughout the U.S., Europe, Japan and APAC.

To the extent that this news release discusses expectations or otherwise makes statements about the future, such statements are forward-looking and are subject to a number of risks and uncertainties that could cause actual results to differ materially from the statements made. These factors include the risks discussed in the Business Description and Management's Discussion and Analysis sections of Veeco's Annual Report on Form 10-K for the year ended December 31, 2008 and in our subsequent quarterly reports on Form 10-Q, current reports on Form 8-K and press releases. Veeco does not undertake any obligation to update any forward-looking statements to reflect future events or circumstances after the date of such statements.

For more information, please click here

Contacts:

Investor Contact:

Deb Wasser

SVP

Investor Relations

1-516-677-0200 x 1472

Trade Media Contact:

Fran Brennen

Senior Director of Marcom

1-516-677-0200 x1222

Copyright © Veeco Instruments Inc.

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Thin films

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Tools

![]() Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

Ferroelectrically modulate the Fermi level of graphene oxide to enhance SERS response November 3rd, 2023

![]() The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

The USTC realizes In situ electron paramagnetic resonance spectroscopy using single nanodiamond sensors November 3rd, 2023

Energy

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

The efficient perovskite cells with a structured anti-reflective layer – another step towards commercialization on a wider scale October 6th, 2023

Solar/Photovoltaic

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

![]() Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

Shedding light on unique conduction mechanisms in a new type of perovskite oxide November 17th, 2023

![]() Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

Inverted perovskite solar cell breaks 25% efficiency record: Researchers improve cell efficiency using a combination of molecules to address different November 17th, 2023

![]() Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

Charged “molecular beasts” the basis for new compounds: Researchers at Leipzig University use “aggressive” fragments of molecular ions for chemical synthesis November 3rd, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||