Home > Press > New Photolithography Technique Advances Nanofabrication Process

|

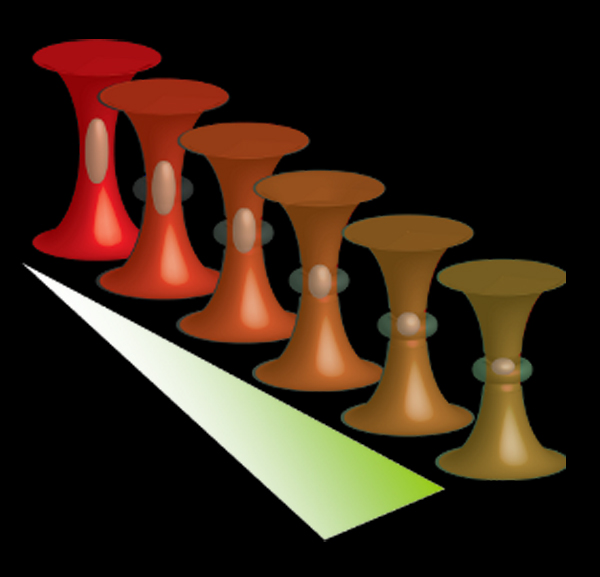

| Schematic depictions of RAPID lithography, the technique developed by John Fourkas and colleagues which enables the creation of features 2500 times smaller than the width of a human hair. |

Abstract:

The ability to create tiny patterns is essential to the fabrication of computer chips as well as to many other current and potential applications of nanotechnology. Yet, creating ever smaller features, through a process called photolithography, has required the use of ultraviolet light, which is difficult and expensive to work with. John Fourkas, Professor of Chemistry and Biochemistry in the University of Maryland College of Chemical and Life Sciences, and his research group have developed a new, table-top technique called RAPID (Resolution Augmentation through Photo-Induced Deactivation) lithography that makes it possible to create small features without the use of ultraviolet light. This research is to be published in Science magazine and released on Science Express on April 9, 2009.

New Photolithography Technique Advances Nanofabrication Process

College Park, MD | Posted on April 15th, 2009Photolithography uses light to deposit or remove material and create patterns on a surface. There is usually a direct relationship between the wavelength of light used and the feature size created. Therefore, nanofabrication has depended on short wavelength ultraviolet light to generate ever smaller features.

"The RAPID lithography technique we have developed enables us to create patterns twenty times smaller than the wavelength of light employed," explains Dr. Fourkas, "which means that it streamlines the nanofabrication process. We expect RAPID to find many applications in areas such as electronics, optics, and biomedical devices."

"If you have gotten a filling at the dentist in recent years," says Fourkas, "you have seen that a viscous liquid is squirted into the cavity and a blue light is then used to harden it. A similar process of hardening using light is the first element of RAPID. Now imagine that your dentist could use a second light source to sculpt the filling by preventing it from hardening in certain places. We have developed a way of using a second light source to perform this sculpting, and it allows us to create features that are 2500 times smaller than the width of a human hair."

Both of the laser light sources used by Fourkas and his team were of the same color, the only difference being that the laser used to harden the material produced short bursts of light while the laser used to prevent hardening was on constantly. The second laser beam also passed through a special optic that allowed for sculpting of the hardened features in the desired shape.

"The fact that one laser is on constantly in RAPID makes this technique particularly easy to implement," says Fourkas, "because there is no need to control the timing between two different pulsed lasers."

Fourkas and his team are currently working on improvements to RAPID lithography that they believe will make it possible to create features that are half of the size of the ones they have demonstrated to date.

Achieving lambda/20 Resolution by One-Color Initiation and Deactivation of Polymerization was written by Linjie Li, Rafael R. Gattass, Erez Gershgorem, Hana Hwang and John T. Fourkas.

####

For more information, please click here

Contacts:

College of Chemical & Life Science

University of Maryland

College Park, MD 20742

Copyright © University of Maryland

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Videos/Movies

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

![]() Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Visualizing the invisible: New fluorescent DNA label reveals nanoscopic cancer features March 4th, 2022

Chip Technology

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

![]() HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

HKUST researchers develop new integration technique for efficient coupling of III-V and silicon February 16th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||