Home > Press > Columbia Engineers Prove Graphene is the Strongest Material

|

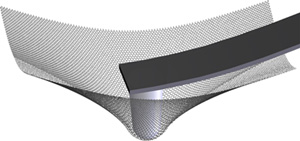

| A representation of a diamond tip with a two nanometer radius indenting into a single atomic sheet of graphene |

Abstract:

Research scientists at Columbia University's Fu Foundation School of Engineering and Applied Science have achieved a breakthrough by proving that the carbon material graphene is the strongest material ever measured.

Columbia Engineers Prove Graphene is the Strongest Material

New York, NY | Posted on July 22nd, 2008Graphene holds great promise for the development of nano-scale devices and equipment. It consists of a single layer of graphite atoms arranged in a hexagonal lattice, similar to a honeycomb. As a two-dimensional material, every atom is exposed to the surface. It forms the basis of graphite fibers used in tennis racquets and other durable products. When rolled, very useful tiny tubes called nanotubes can be fabricated.

Until now, graphene's estimated strength, elasticity and breaking point were based on complex computer modeling theories. Laboratory tests had been stymied because of two major experimental challenges: the complexity in mechanically grasping graphene specimens to measure their elongation under force, and the difficulty of making specimens small enough to be free of imperfections.

"Our team sidestepped the size issue by creating samples small enough to be defect-free," said Columbia Professor Jeffrey Kysar.

The studies were conducted by postdoctoral researcher Changgu Lee and graduate student Xiaoding Wei, in the research groups of mechanical engineering professors Kysar and James Hone. The findings are published in the latest issue of Science.

"Our research establishes graphene as the strongest material ever measured, some 200 times stronger than structural steel," Hone said. "It would take an elephant, balanced on a pencil, to break through a sheet of graphene the thickness of Saran Wrap."

The team culled microscopic graphene samples, in which every single atom is on the surface, from larger graphite crystals. These newly created, two-dimensional samples were then placed over small circular holes etched in silicon to create miniature circular films only one atom thick. The graphene adhered to the silicon because of the attraction between their atoms.

The scientists tested the strength of the films by pushing on their centers with a diamond-tipped atomic force microscope with a radius of 20 billionths of a meter. The absence of flaws in the samples, each about one micron in diameter (one percent of the width of a human hair), enabled the scientists to test both elasticity and breaking point properties. The scientists collected more than 67 test values on 23 separate films.

"Until now, there's been no definitive set of experiments that people can use to validate or invalidate the computer simulations that model the mechanical properties of materials at strains literally up to the breaking point, " said Kysar. "It's important because this is a fundamental parameter for all types of materials.

"The Air Force wants to introduce new materials within a five-year cycle, versus 20 years now, so being able to predict the mechanical behavior of how a new material will fail under the most extreme circumstances will make it much less expensive and less time consuming to develop, and with better materials for everyday life."

"Though the strength of any practical material is still limited by many types of defects, the research can lead to a better understanding of the behavior of materials at extreme conditions, such as [those that] exist near the tip of a crack," said Hone. "This can in turn lead to far more robust materials, ones more resistant to oxidation and fatigue. Achieving a better understanding of how materials fail allows us to design and create newer, safer materials, and ultimately to build a safer, more efficient environment for us."

####

For more information, please click here

Copyright © Columbia University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||