Home > Press > Nano-boric acid makes motor oil more slippery

|

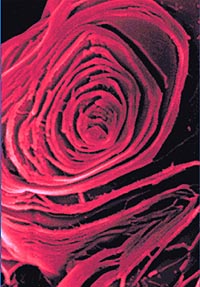

| This boric acid "rose" shows the intricately layered microscopic structure of the compound. |

Abstract:

One key to saving the environment, improving our economy and reducing our dependence on foreign oil might just be sitting in your mother's medicine cabinet.

Nano-boric acid makes motor oil more slippery

ARGONNE, IL | Posted on August 6th, 2007Scientists at the U.S. Department of Energy's Argonne National Laboratory have begun to combine infinitesimal particles of boric acid — known primarily as a mild antiseptic and eye cleanser — with traditional motor oils in order to improve their lubricity and by doing so increase energy efficiency.

Ali Erdemir, senior scientist in Argonne's Energy Systems Division, has spent nearly 20 years investigating the lubricious properties of boric acid. In 1991, he received an R&D 100 award — widely considered the "Oscar of technology" — for showing that microscopic particles of boric acid could dramatically reduce friction between automobile engine parts. Metals covered with a boric acid film exhibited coefficients of friction lower than that of Teflon, making Erdemir's films the slickest solids in existence at that time.

"Ali was looking at large, micron-sized, particles," said George Fenske, who works alongside Erdemir at Argonne. "He was just sprinkling boric acid onto surfaces."

But driven by a conviction that he could fashion boric acid into an even better lubricant, Erdemir continued to chase the ultimate frontier: a perfectly frictionless material. Glimpsing the potential of nanotechnology, Erdemir went smaller — 10 times smaller — and was astonished by the behavior of much thinner boric acid films. "If you can produce or manufacture boric acid at the nanoscale, its properties become even more fantastic," he said.

Reducing the size of the particles to as tiny as 50 nanometers in diameter — less than one-thousandth the width of a human hair — solved a number of old problems and opened up a number of new possibilities, Erdemir said. In previous tests, his team had combined the larger boric acid particles with pure poly-alpha-olefin, the principal ingredient in many synthetic motor oils. While these larger particles dramatically improved the lubricity of the pure oil, within a few weeks gravity had started to separate the mixture. By using smaller particles, Erdemir created a stable suspension of boric acid in the motor oil.

In laboratory tests, these new boric acid suspensions have reduced by as much as two-thirds the energy lost through friction as heat. The implications for fuel economy are not hard to imagine, Erdemir said. "You're easily talking about a four or five percent reduction in fuel consumption," he said. "In a given day, we consume so many millions of barrels of oil, and if you can reduce that number by even one percent, that will have a huge economic impact."

Argonne is currently in talks with materials and lubricant manufacturers to bring boric acid technology to market, Erdemir said. While these new additives need to pass a battery of environmental and safety tests, they will probably be available within two years.

In his first experiments with boric acid, Erdemir demonstrated that the compound not only proved an effective lubricant but was also every industrial technologist's dream: It came from naturally abundant minerals, was cheap to manufacture, and posed no health hazards or environmental threats.

Boric acid owes its lubricious properties to its unique natural structure. The compound consists of a stack of crystallized layers in which the atoms tightly adhere to each other. However, these layers stack themselves relatively far apart, so that the intermolecular bonds — called van der Waals forces — are comparatively weak. When stressed, the compound's layers smear and slide over one another easily, like a strewn deck of playing cards. The strong bonding within each layer prevents direct contact between sliding parts, lowering friction and minimizing wear.

Until recently, most of Erdemir's work in boric acid lubrication had been restricted to motor oils, principally because of the relative bulk of the larger particles. The move to the nanoscale, however, has opened up other possible uses of the chemical. Through a simple chemical reaction, nano-boric acid can be transformed into a liquid relative of boric acid that has shown potential to increase fuel lubricity.

Using this liquid analog of solid boric acid as a fuel additive on a large scale could greatly benefit the environment, both because it would help to increase fuel efficiency and because it would replace existing fuel lubricants that are potentially harmful to the environment, Erdemir said. By themselves, most fuels — especially diesels — contain some sulfur and other special chemical additives to boost lubricity. When burned, however, some of these additives along with sulfur may cause harmful emissions and acid rain. However, the lack of a suitable alternative complicates efforts to cut sulfur content.

The substitution of liquid boric acid for sulfur-containing additives preserves the health of the car as well as that of the environment. Sulfur exhaust gradually coats the surface of a car's catalytic converter, the part that helps to reduce the toxicity of a car's emissions. Eventually, the converter becomes so choked with sulfur that it is no longer able to process any more exhaust.

Even though he has just begun to unleash the potential of boric acid, Erdemir believes that nanoscale synthetic compounds may prove to be even more effective lubricants. "The next step is to use the basic knowledge that we have gained out of this particular compound to come up with more exotic compounds that will work even better," he said. — Jared Sagoff

####

About Argonne National Laboratory

Argonne National Laboratory is one of the U.S. Department of Energy's largest research centers. It is also the nation's first national laboratory, chartered in 1946.

Argonne is a direct descendant of the University of Chicago's Metallurgical Laboratory, part of the World War Two Manhattan Project. It was at the Met Lab where, on Dec. 2, 1942, Enrico Fermi and his band of about 50 colleagues created the world's first controlled nuclear chain reaction in a racquets court at the University of Chicago. After the war, Argonne was given the mission of developing nuclear reactors for peaceful purposes. Over the years, Argonne's research expanded to include many other areas of science, engineering and technology. Argonne is not and never has been a weapons laboratory.

For more information, please click here

Contacts:

Eleanor Taylor

630/252-5565

Copyright © Argonne National Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Automotive/Transportation

![]() Researchers’ approach may protect quantum computers from attacks March 8th, 2024

Researchers’ approach may protect quantum computers from attacks March 8th, 2024

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||