Home > Press > Tough tubes -- Carbon nanotubes endure heavy wear and tear

|

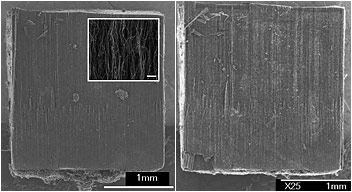

| A block of carbon nanotubes before (left) and after (right) being compressed more than 500,000 times. There is virtually no difference in shape, mechanical integrity or electrical conductivity. This resistance to wear and tear is similar to the behavior of soft tissues such as a shoulder muscle or stomach wall. Photo Credit: Victor Pushparaj |

Abstract:

Study suggests nanotube structures hold potential for creating synthetic tissue, muscles

Tough tubes -- Carbon nanotubes endure heavy wear and tear

Troy, NY | Posted on July 2nd, 2007The ability of carbon nanotubes to withstand repeated stress yet retain their structural and mechanical integrity is similar to the behavior of soft tissue, according to a new study from Rensselaer Polytechnic Institute.

When paired with the strong electrical conductivity of carbon nanotubes, this ability to endure wear and tear, or fatigue, suggests the materials could be used to create structures that mimic artificial muscles or interesting electro-mechanical systems, researchers said.

The report, "Fatigue resistance of aligned carbon nanotube arrays under cyclic compression," appears in the July issue of Nature Nanotechnology. Despite extensive research over the past decade into the mechanical properties of carbon nanotube structures, this study is the first to explore and document their fatigue behavior, said co-author Victor Pushparaj, a senior research specialist in Rensselaer's department of materials science and engineering.

"The idea was to show how fatigue affects nanotube structures over the lifetime of a device that incorporates carbon nanotubes," Pushparaj said. "Even when exposed to high levels of stress, the nanotubes held up extremely well. The behavior is reminiscent of the mechanics of soft tissues, such as a shoulder muscle or stomach wall, which expand and contract millions of times over a human lifetime."

Pushparaj and his team created a free-standing, macroscopic, two-millimeter square block of carbon nanotubes, made up of millions of individual, vertically aligned, multiwalled nanotubes. The researchers then compressed the block between two steels plates in a vice-like machine.

The team repeated this process more than 500,000 times, recording precisely how much force was required to compress the nanotube block down to about 25 percent of its original height.

Even after 500,000 compressions, the nanotube block retained its original shape and mechanical properties. Similarly, the nanotube block also retained its original electrical conductance.

n the initial stages of the experiment, the force needed to compress the nanotube block decreased slightly, but soon stabilized to a constant value, said Jonghwan Suhr, an assistant professor of mechanical engineering at the University of Nevada in Reno, who received his doctorate from Rensselaer in 2005, and with Pushparaj contributed equally to this report.

As the researchers continued to compress the block, the individual nanotube arrays collectively and gradually adjusted to getting squeezed, showing very little fatigue. This "shape memory," or viscoelastic-like behavior (although the individual nanotubes are not themselves viscoelastic), is often observed in soft-tissue materials.

While more promising than polymers and other engineered materials that exhibit shape memory, carbon nanotubes by themselves do not perform well enough to be used as a synthetic biomaterial. But Pushparaj and his fellow researchers are combining carbon nanotubes with different polymers to create a material they anticipate will perform as well as soft tissue. The team is also using results from this study to develop mechanically compliant electrical probes and interconnects.

n addition to Pushparaj and Suhr, other contributing authors of the paper include Pulickel Ajayan, the Henry Burlage Professor of Materials Science and Engineering at Rensselaer; Omkaram Nalamasu, professor of chemistry and materials science and engineering at Rensselaer; Lijie Ci, Rensselaer research associate; Subbalakshmi Sreekala, a research associate in the department of mechanical and aerospace engineering at Princeton University; and X. Zhang, research associate in the school of materials science and engineering at Shanghai Jiao Tong University.

Funding for the project was provided by the Focus Center New York for Interconnects.

####

About Rensselaer Polytechnic Institute

Rensselaer Polytechnic Institute, founded in 1824, is the nationís oldest technological university. The university offers bachelorís, masterís, and doctoral degrees in engineering, the sciences, information technology, architecture, management, and the humanities and social sciences. Institute programs serve undergraduates, graduate students, and working professionals around the world. Rensselaer faculty are known for pre-eminence in research conducted in a wide range of fields, with particular emphasis in biotechnology, nanotechnology, information technology, and the media arts and technology. The Institute is well known for its success in the transfer of technology from the laboratory to the marketplace so that new discoveries and inventions benefit human life, protect the environment, and strengthen economic development.

For more information, please click here

Contacts:

Michael Mullaney

518-276-6161

518.698.6336 (cell)

Copyright © Rensselaer Polytechnic Institute

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings

![]() Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

Tests find no free-standing nanotubes released from tire tread wear September 8th, 2023

![]() Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Detection of bacteria and viruses with fluorescent nanotubes July 21st, 2023

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navyís quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navyís quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||