Home > Press > Crucial Clue to Nanofiber Fabrication Technique

Fingerprints Provide Crucial Clue to New Nanofiber Fabrication Technique

University Park, PA | Posted on January 26, 2006

Fingerprints are usually used to identify people but, this time, they gave Penn State chemical engineers the crucial clue needed to discover an easy, versatile new method for making nanofibers that have potential uses in advanced filtration as well as wound care, drug delivery, bioassays and other medical applications.

The new technique is based on the way forensic scientists develop fingerprints from a crime scene and is easier and more versatile than either of the current methods, templates or electrospinning, used commercially to make nanofibers.

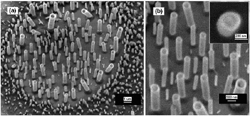

The first nanofibers generated by the technique are made from the basic ingredient of Super Glue, cyanoacrylate, which is a biologically-compatible material already used in liquid sutures, spheres for drug delivery and in experimental cancer treatment. However, the researchers say that other materials, like cyanoacrylate, that form solid polymers when nudged by a catalyst could potentially also be used in the process.

Dr. Henry C. Foley, professor of chemical engineering who directed the project, says, "The new technique is so versatile that it allows us not only to make nano-scale fibers but also nano-sized flat sheets, spheres and even wrinkled sheets that look tortellini-like."

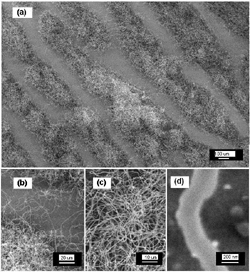

The researchers can also generate patterned surfaces and say that the process could conceivably be used in an ink jet printer.

The research is detailed in a paper, "Facile Catalytic Growth of Cyanoacrylate Nanofibers," published online today (Jan. 26) in the British journal, The Royal Society of Chemistry, Chemical Communications. The authors are Pratik J. Mankidy, doctoral candidate in chemical engineering; Ramakrishnan Rajagopalan, research associate at Penn State's Materials Research Laboratory, and Foley, who is also associate vice president for research at the University. The journal is available here.

Foley explains that forensic scientists develop latent fingerprints via a process known as cyanoacrylate fuming. Fingerprints left on a surface are exposed to fumes of cyanoacrylate, which form a white polymer residue that makes the ridges of the fingerprint visible.

One of the researchers, Pratik Mankidy, had accidentally left his fingerprints on a piece of research equipment that had been secured with Super Glue and nanofibers appeared. Putting two and two together, the researchers set out to discover what constituents of fingerprints trigger the cyanoacrylate polymerization on the ridges of fingerprints.

They made synthetic fingerprints from a mixture of a known polymer initiator, common table salt in water, and a non-initiator, linoleic acid, found on fingers. Then they exposed the fake prints to cyanoacrylate fuming. Sure enough, they got nanofibers similar to the ones Mankidy’s fingerprints had generated accidentally. They also fumed cyanoacrylate on single initiators and found that sodium hydroxide, potassium hydroxide and potassium acetate produced tortellini-like films of the polymer. When ammonium hydroxide was fumed with cyanoacrylate, it produced nano-sized spheres.

The researchers note that the role played by the presence of the non-initiating components in the fingerprint mixture is not completely understood. They are continuing their experiments to understand the process more completely.

A majority of the fibers produced by the new process have diameters in the 200-250 nanometer range and are hundreds of microns long. Typically, nanofibers that are currently commercially available are in this same range.

Foley notes, "Our findings open up a whole new world of opportunity for control of nanoscale structures through chemistry via catalysis."

The research was supported by a grant from the National Science Foundation.

Barbara Hale

(814) 865-9481

bah@psu.edu

A'ndrea Elyse Messer

Science & Research Information Officer

Penn State

814-865-9481

814-865-9421

aem1@psu.edu

Copyright © Penn State

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Possible Futures

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

With VECSELs towards the quantum internet Fraunhofer: IAF achieves record output power with VECSEL for quantum frequency converters April 5th, 2024

Nanomedicine

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

Good as gold - improving infectious disease testing with gold nanoparticles April 5th, 2024

![]() Researchers develop artificial building blocks of life March 8th, 2024

Researchers develop artificial building blocks of life March 8th, 2024

Materials/Metamaterials/Magnetoresistance

![]() Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

Nanoscale CL thermometry with lanthanide-doped heavy-metal oxide in TEM March 8th, 2024

![]() Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Focused ion beam technology: A single tool for a wide range of applications January 12th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||