Home > Press > Russian scientists improve 3D printing technology for aerospace composites using oil waste

|

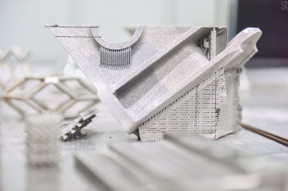

| Aviation parts printed on a 3D printer from new metal powders CREDIT Sergey Gnuskov/NUST MISIS |

Abstract:

Scientists from NUST MISIS have improved the technology of 3D printing from aluminum, having achieved an increase in the hardness of products by 1,5 times. The nanocarbon additive to aluminum powder, which they have developed, obtained from the products of processing associated petroleum gas, will improve the quality of 3D printed aerospace composites. The research results are published in the international scientific journal Composites Communications

Russian scientists improve 3D printing technology for aerospace composites using oil waste

Moscow, Russia | Posted on November 27th, 2020Today, the main field of application for aluminum 3D printing is the creation of high-tech parts for the aviation and space industries. The presence of even the slightest defects in printed structures is critical to the safety of the technology being created. According to NUST MISIS scientists, the main risk of such defects is the high porosity of the material, caused, among other reasons, by the qualities of the original aluminum powder. To ensure a uniform and dense microstructure of printed products, scientists from the MISIS Catalis Lab proposed adding carbon nanofibers to the aluminum powder. The use of this modifying additive makes it possible to ensure a low porosity of the material and an increase in its hardness by 1.5 times.

"Changing the chemical and phase composition of the powder for printing by introducing additional components into the main matrix allows improving its properties. In particular, carbon nanofibers have high thermal conductivity, which helps to minimize temperature gradients between printed layers during product synthesis, at the stage of selective laser melting. Thanks to this, the microstructure of the material can be almost completely eliminated from inhomogeneities," said the head of the laboratory, professor at NUST MISIS, Ph.D. Alexander Gromov.

The technology for the synthesis of nanocarbon additives developed by the research team includes methods of chemical deposition, ultrasonic treatment, and IR heat treatment. The used carbon nanofibers must be a by-product of associated petroleum gas processing. During its catalytic decomposition, carbon accumulates in the form of nanofibers on dispersed metal particles of the catalyst. Usually, at present, associated gases are simply burned in the fields, which harms the environment. Therefore, the application of the new method also has a serious environmental significance, -- said Professor Gromov. The study has been carried out jointly with specialists from the Boreskov Institute of Catalysis SB RAS. In the future, the research team plans to determine the optimal conditions for selective laser melting of new composite powders, as well as to develop a technology for post-processing and industrial use of synthesized products.

####

For more information, please click here

Contacts:

Lyudmila Dozhdikova

892-504-31990

Copyright © National University of Science and Technology MISIS

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Possible Futures

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Discoveries

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Aerospace/Space

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

![]() The National Space Society Congratulates SpaceX on Starship’s 7th Test Flight: Latest Test of the Megarocket Hoped to Demonstrate a Number of New Technologies and Systems January 17th, 2025

The National Space Society Congratulates SpaceX on Starship’s 7th Test Flight: Latest Test of the Megarocket Hoped to Demonstrate a Number of New Technologies and Systems January 17th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||