Home > Press > Particle size matters for porous building blocks: Rice University scientists find porous nanoparticles get tougher under pressure, but not when assembled

|

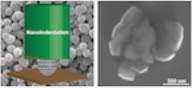

| Rice University materials scientists synthesized spherical, porous nanoparticles of calcium and silicate, formed films and pellets and tested their toughness under pressure from a nanoindenter. They found films made of larger particles approaching 500 nanometers were much tougher and the films and pellets less prone to cracking under pressure. At right, small particles are deformed after nanoindentation. (Credit: Multiscale Materials Laboratory/Rice University) Rice University materials scientists synthesized spherical, porous nanoparticles of calcium and silicate, formed films and pellets and tested their toughness under pressure from a nanoindenter. They found films made of larger particles approaching 500 nanometers were much tougher and the films and pellets less prone to cracking under pressure. At right, small particles are deformed after nanoindentation. (Credit: Multiscale Materials Laboratory/Rice University) |

Abstract:

Porous particles of calcium and silicate show potential as building blocks for a host of applications like self-healing materials, bone-tissue engineering, drug delivery, insulation, ceramics and construction materials, according to Rice University engineers who decided to see how well they perform at the nanoscale.

Particle size matters for porous building blocks: Rice University scientists find porous nanoparticles get tougher under pressure, but not when assembled

Houston, TX | Posted on December 19th, 2017Following previous work on self-healing materials using porous building blocks, Rice materials scientist Rouzbeh Shahsavari and graduate student Sung Hoon Hwang made a wide range of porous particles between 150 and 550 nanometers in diameter -- thousands of times smaller than the thickness of a sheet of paper -- with pores about the width of a strand of DNA.

They then assembled the particles into micron-sized sheets and pellets to see how well the arrays held up under pressure from a nanoindenter, which tests the hardness of a material.

The results of more than 900 tests, reported this month in the American Chemical Society's ACS Applied Materials and Interfaces, showed that bigger individual nanoparticles were 120 percent tougher than smaller ones.

This, Shahsavari said, was clear evidence of an intrinsic size effect where particles between 300 and 500 nanometers went from brittle to ductile, or pliable, even though they all had the same small pores that were 2 to 4 nanometers. But they were surprised to find that when the same big particles were stacked, the size effect didn't carry over entirely to the larger structures.

The principles revealed should be important to scientists and engineers studying nanoparticles as building blocks in all kinds of bottom-up fabrication.

“With porous building blocks, controlling the link between porosity, particle size and mechanical properties is essential to the integrity of the system for any application," Shahsavari said. "In this work, we found there is a brittle-to-ductile transition when increasing the particle size while keeping the pore size constant.

"This means that larger submicron calcium-silicate particles are tougher and more flexible compared with smaller ones, making them more damage-tolerant," he said.

The lab tested self-assembled arrays of the tiny spheres as well as arrays compacted under the equivalent of 5 tons inside a cylindrical press.

Four sizes of spheres were allowed to self-assemble into films. When these were subject to nanoindentation, the researchers found the intrinsic size effect largely disappeared as the films showed variable stiffness. Where it was thin, the weakly bonded particles simply made way for the indenter to sink through to the glass substrate. Where it was thick, the film cracked.

“We observed that the stiffness increases as a function of applied indentation forces because as the maximum force is increased, it leads to a greater densification of the particles under load," Shahsavari said. "By the time the peak load is reached, the particles are quite densely packed and start behaving collectively as a single film."

Pellets made of compacted nanospheres of various diameters deformed under pressure from the nanoindenter but showed no evidence of getting tougher under pressure, they reported.

"As a next step, we're interested in fabricating self-assembled superstructures with tunable particle size that better enable their intended functionalities, like loading and unloading with stimuli-sensitive sealants, while offering the best mechanical integrity," Shahsavari said.

The National Science Foundation supported the research.

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,879 undergraduates and 2,861 graduate students, Rice’s undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for quality of life and for lots of race/class interaction and No. 2 for happiest students by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance. To read “What they’re saying about Rice,” go to http://tinyurl.com/RiceUniversityoverview .

Follow Rice News and Media Relations via Twitter @RiceUNews

For more information, please click here

Contacts:

David Ruth

713-348-6327

Mike Williams

713-348-6728

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Multiscale Materials Laboratory (Shahsavari Lab):

Multiscale Materials Laboratory (Shahsavari Lab):

![]() George R. Brown School of Engineering:

George R. Brown School of Engineering:

![]() Rice Department of Civil and Environmental Engineering:

Rice Department of Civil and Environmental Engineering:

![]() Rice Department of Materials Science and NanoEngineering:

Rice Department of Materials Science and NanoEngineering:

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Self Assembly

![]() Diamond glitter: A play of colors with artificial DNA crystals May 17th, 2024

Diamond glitter: A play of colors with artificial DNA crystals May 17th, 2024

![]() Liquid crystal templated chiral nanomaterials October 14th, 2022

Liquid crystal templated chiral nanomaterials October 14th, 2022

![]() Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

Nanoclusters self-organize into centimeter-scale hierarchical assemblies April 22nd, 2022

![]() Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

Atom by atom: building precise smaller nanoparticles with templates March 4th, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||