Home > Press > UV-sensors from the oven: cientists at Kiel University revolutionize the nanostructure production process

|

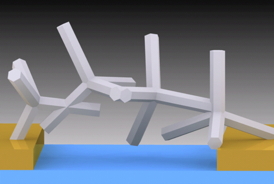

| Schematic represenation of zinc oxide nanostructures, which were produced by burner-flame transport synthesis, bridging two contacts. Photo/Copyright: Mishra/Advanced Materials |

Abstract:

Placed in fire detectors and water treatment units UV-sensors can save lives; also in many areas of industry and environment the demand for these devices is rising steadily. Scientists of Kiel University have been able to "bake" nanostructures within seconds, in order to fabricate very fast UV-sensors. This new technique totally diminishes the need to use sophisticated equipments and toxic chemicals. It will therefore be highly interesting for companies. The scientists have published their results today (November 19) in Advanced Materials, a very renowned scientific magazine.

UV-sensors from the oven: cientists at Kiel University revolutionize the nanostructure production process

Kiel, Germany | Posted on November 20th, 2013When building a sensor device from nanostructures, one of the biggest challenges is how to interconnect them into electrical contacts in chips because of their extremely small dimensions in nanoscale range, says Dawit Gedamu, the first author of the paper. Most of the existing synthesis methods, such as Chemical Vapour Deposition or Vapor-Liquid-Solid (VLS) growth allow synthesis of different nanostructures only under specific conditions. For instance, the presence of catalytic particles, particular substrates, complex temperature, atmospheric conditions and many more factors must be met. Furthermore, to integrate the synthesized nanostructures with these techniques in the chips requires another very sophisticated step. There are silicon or gallium nitride based UV detectors already available in the market but they lack a certain level of selectivity and also they cannot function in harsh environments. High production costs, multistep processes and the requirement of specific operating conditions limit the field of application for these sensors.

"Extremely promising" for various applications are the sensors that are based on zinc oxide, says Dr. Yogendra Kumar Mishra, scientific assistant with the work group "Functional Nanomaterials" at Kiel University and main author of the study. "Nanostructures made from zinc oxide are highly interesting for multifunctional applications, due to their sensibility to UV light and their electrical and mechanical properties", says Mishra. Also, the material is relatively inexpensive and easy to synthesize. Since up to a certain level zinc is necessary for human organisms, these zinc oxide nano-microstructures could be of potential interest for biomedical engineering.

The scientists have fabricated a network of interconnected zinc oxide nano-tetrapods as a bridge between electrodes on a chip by a new single step flame transport synthesis process: In a simple oven or airbrush gun-type burner it only needs high temperature to convert zinc microparticles into nano-micro tetrapods. This process takes place in normal air environment and the necessary amount of oxygen is regulated by the flame itself. "This burner-flame transport synthesis method allows us to grow the zinc oxide nano-microstructures directly on the chip - and that only takes a few seconds, it is just a matter of driving the chip through the flame while the nano tetrapods assemble themselves onto it!" Mishra is excited to report. The high temperature of the flame ensures contacts of good quality between chip and the nanostructures, which is highly desirable for a better performance of the device.

The result: the sensor produced by the Kiel University scientists reacts to UV light within milliseconds of its exposure. Additionally, it also works in rather rough environments. These simple and inexpensive manufacturing conditions as well as the usage of pure zinc microparticles make this production method at the laboratories at Kiel University highly attractive for manufacturing companies. "We already had regional companies inquiring about our work. It shows that our basic research can be transferred into concrete applications", Professor Rainer Adelung, head of the research team, explains. The next logical step for the material scientists is therefore to find the ways to produce these nano-tetrapods on a larger scale.

One curious fact: Zinc oxide nanostructures started their career as waste from conventional VLS growth experiments for zinc oxide. One day, Yogendra Mishra examined the crystals that looked like artificial snow under the microscope: "Their particular intertwining structure and their ability to detect light implied an enormous potential", says the scientist, who was holding a fellowship from the Alexander von Humboldt Foundation while developing the new method in the years following this discovery. To successfully produce the nano-tetrapods, the right combination of temperature and mixing ratio of zinc particles and sacrificial polymer as well as other parameters had to be investigated.

Nano science is strong at Kiel University. Two big Collaborative Research Centres (CRC) provided Mishra with necessary resources and expertise. There, almost 200 scientists work meticulously on molecules, which can be switched on and off by light in order to take over certain functions (CRC 677 "Function by Switching"), and on new materials, which are capable of measuring tiny magnetic fields in the human brain and heart (CRC 855 "Magnetoelectric Composites - Future Biomagnetic Interfaces"). Developing new diagnostic methods and devices is their goal. The German Research Foundation (DFG) supports their research.

Full bibliographic information

Rapid fabrication technique for interpenetrated ZnO nanotetrapod networks for fast UV-sensors; Dawit Gedamu, Ingo Paulowicz, Sören Kaps, Oleg Lupan, Sebastian Wille, Galina Haidarschin, Yogendra Kumar Mishra, Rainer Adelung; Advanced Materials; DOI: 10.1002/adma.201304363

####

About Christian-Albrechts-Universitaet zu Kiel

When Duke Christian Albrecht of Holstein-Gottorp decided to found a university in 1665, the Thirty Years' War was over. The State required well-educated young men for service to government, who were to graduate from the new university. 140 students enrolled in the initially established faculties of Theology, Law, Medicine and Philosophy.

The University currently teaches over 24,000 women and men and the range of subjects on offer is spread over eight faculties. In addition to the original faculties, the faculties of Agricultural and Nutritional Science, Mathematics and Natural Sciences, Business, Economics and Social Sciences and, the newest faculty, the Faculty of Engineering are integrated into the university. Where once Max Planck and Heinrich Hertz worked, around 700 academics now pass on their knowledge to students from Germany and across the Globe.

For more information, please click here

Contacts:

Dr. Yogendra Kumar Mishra

Funktionale Nanomaterialien

Institut für Materialwissenschaft

Christian-Albrechts-Universität zu Kiel

Tel.: +40 (0)431/880 6195

Prof. Dr. Rainer Adelung

Funktionale Nanomaterialien

Institut für Materialwissenschaft

Christian-Albrechts-Universität zu Kiel

Tel.: +49 (0)431/880 6116

Christian-Albrechts-Universität zu Kiel

Press

communication and marketing

Dr. Boris Pawlowski

text: Denis Schimmelpfennig

translation: Ann-Christin Wimber

Address: D-24098 Kiel

telephone: +49 (0)431 880-2104

fax: +49 (0)431 880-1355

Copyright © AlphaGalileo

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Sensors

Discoveries

![]() Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

Chemical reactions can scramble quantum information as well as black holes April 5th, 2024

![]() New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

New micromaterial releases nanoparticles that selectively destroy cancer cells April 5th, 2024

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Announcements

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

Simulating magnetization in a Heisenberg quantum spin chain April 5th, 2024

![]() Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Discovery points path to flash-like memory for storing qubits: Rice find could hasten development of nonvolatile quantum memory April 5th, 2024

Water

![]() Taking salt out of the water equation October 7th, 2022

Taking salt out of the water equation October 7th, 2022

Industrial

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

![]() Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

Nanotubes: a promising solution for advanced rubber cables with 60% less conductive filler June 1st, 2022

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

OCSiAl receives the green light for Luxembourg graphene nanotube facility project to power the next generation of electric vehicles in Europe March 4th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||